Solid and Fluid Coupling of OpenMC and MOOSE

In this tutorial, you will learn how to:

Couple OpenMC to 2 separate MOOSE applications solving for the solid and fluid thermal-fluids

Couple OpenMC to mixed-dimension feedback with 3-D heat conduction and 1-D fluid flow

Establish coupling between OpenMC and MOOSE for nested universe OpenMC models

Apply homogenized temperature feedback to heterogeneous OpenMC cells

To access this tutorial:

cd cardinal/tutorials/gas_assembly

This tutorial also requires you to download an OpenMC XML file from Box. Please download the files from the gas_assembly folder here and place these files within the same directory structure in tutorials/gas_assembly.

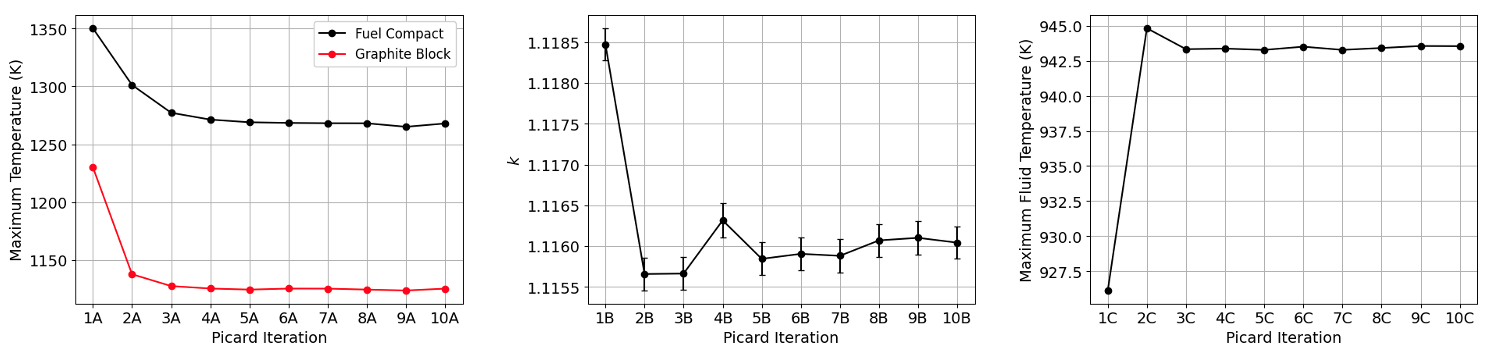

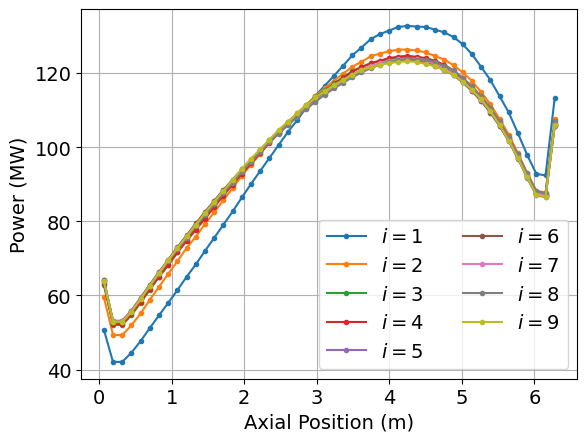

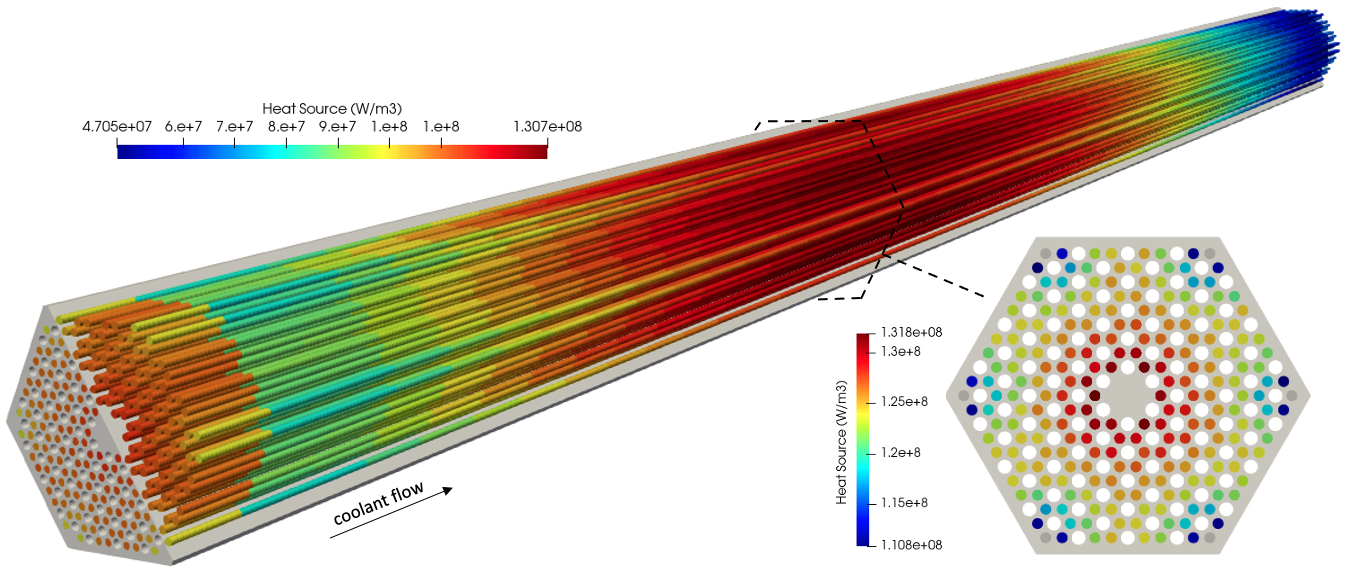

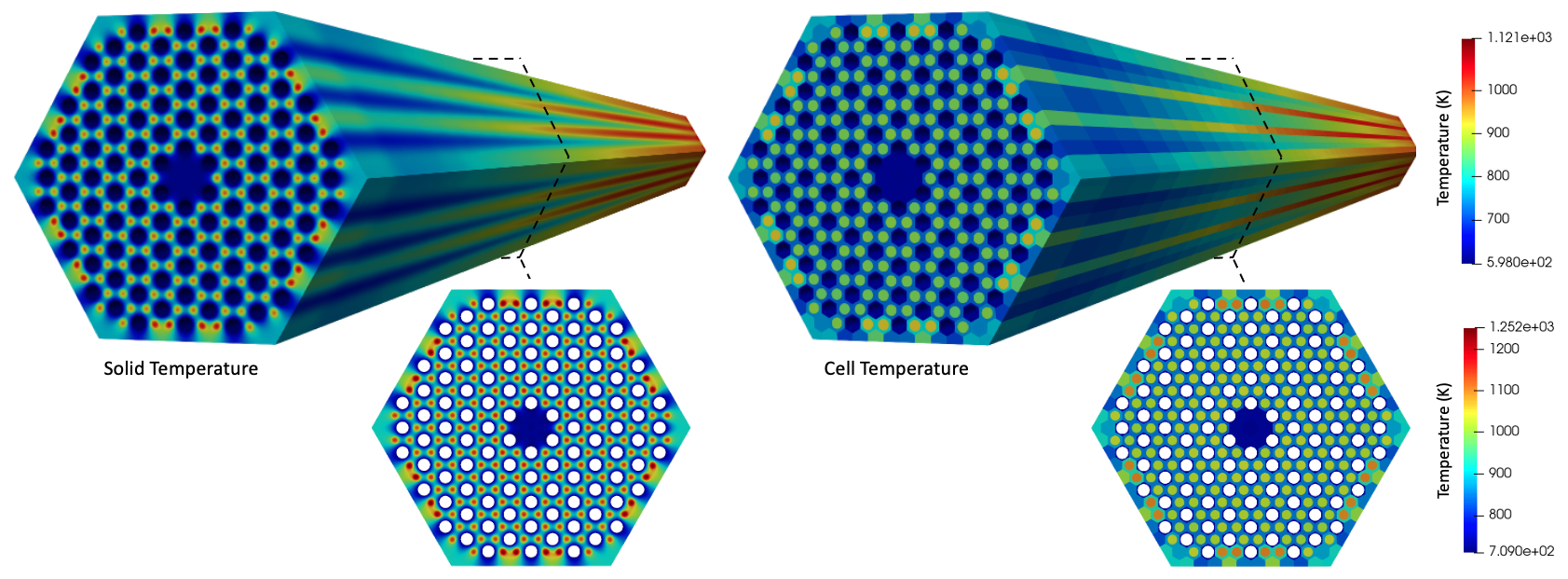

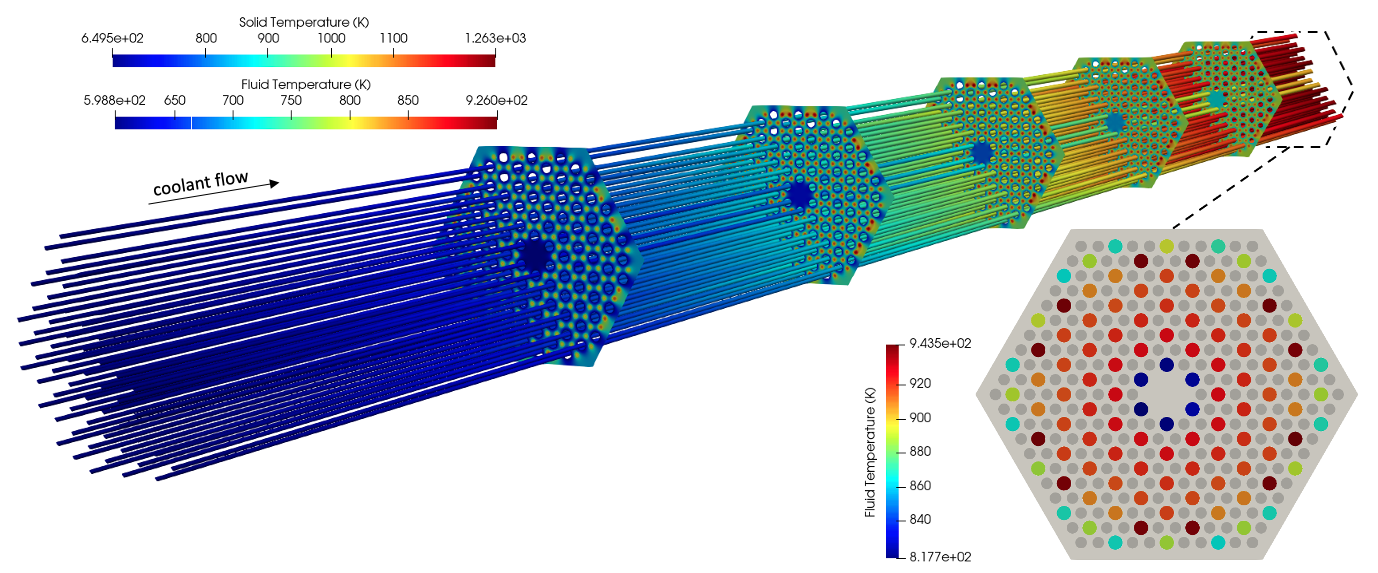

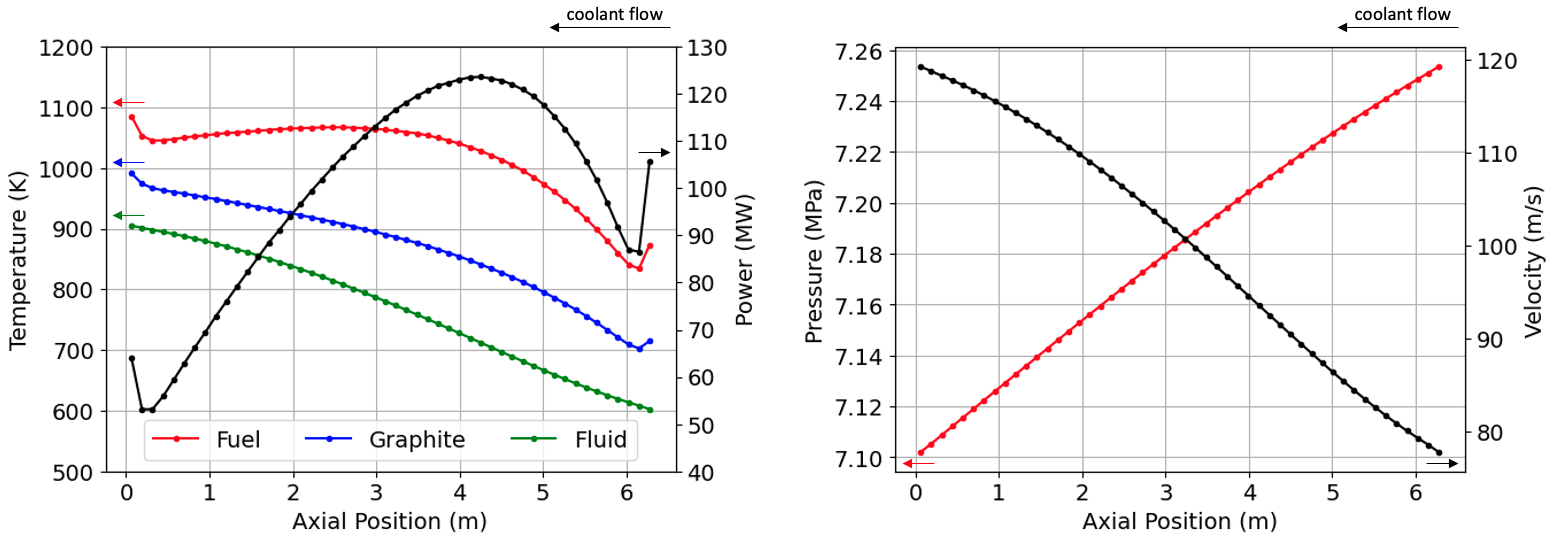

In this tutorial, we couple OpenMC to the MOOSE heat transfer module and the Thermal Hydraulics Module (THM) , a set of 1-D systems-level thermal-hydraulics kernels. OpenMC will receive temperature feedback from both the MOOSE heat transfer module (for the solid regions) and from THM (for the fluid regions). Density feedback will be provided by THM for the fluid regions. This tutorial models a full-height Tri-Structural Isotropic (TRISO)-fueled prismatic gas reactor fuel assembly, and is an extension of an earlier tutorial which coupled OpenMC and MOOSE heat conduction (i.e. without an application providing fluid feedback) for a unit cell version of the same geometry. In this tutorial, we add fluid feedback and also describe several nuances associated with setting up feedback in OpenMC lattices.

This tutorial was developed with support from the NEAMS Thermal Fluids Center of Excellence. A paper Novak et al. (2021) describing the physics models and mesh refinement studies provides additional context beyond the scope of this tutorial.

Due to the tall height of the full assembly (about 6 meters), the converged results shown in Novak et al. (2021) and in the figures in this tutorial used a finer mesh and more particles than in the input files we set up for this tutorial - the input files in this tutorial still require parallel resources to run, but should be faster-running. Parameters that have been set to coarser values are noted where applicable.

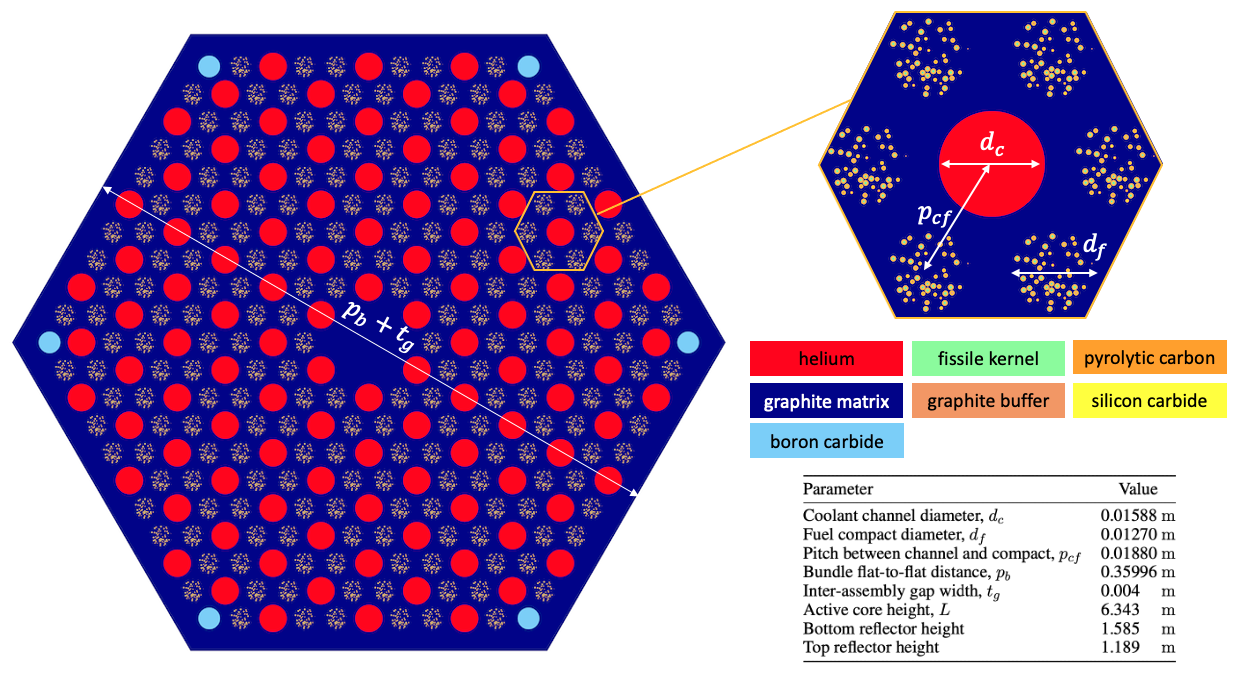

Geometry and Computational Model

The geometry consists of a TRISO-fueled gas reactor assembly INL (2016). A top-down view of the geometry is shown in Figure 1. The assembly is a graphite prismatic hexagonal block with 108 helium coolant channels, 210 fuel compacts, and 6 poison compacts. Each fuel compact contains TRISO particles dispersed in a graphite matrix with a packing fraction of 15%. All channels and compacts are ordered in a triangular lattice with pitch . Due to irradiation- and temperature-induced swelling of graphite, small helium gaps exist between assemblies. In this tutorial, rather than explicitly model the inter-assembly flow, we treat the gap regions as solid graphite. There are also graphite reflectors above and below the assembly.

Figure 1: TRISO-fueled gas reactor fuel assembly

The TRISO particles use a conventional design that consists of a central fissile uranium oxycarbide kernel enclosed in a carbon buffer, an inner Pyrolitic Carbon (PyC) layer, a silicon carbide layer, and finally an outer PyC layer. The geometric specifications for the assembly dimensions are shown in Figure 1, while dimensions for the TRISO particles are summarized in Table 1.

Table 1: Geometric specifications for the TRISO particles

| Parameter | Value (cm) |

|---|---|

| TRISO kernel radius | 214.85e-4 |

| Buffer layer radius | 314.85e-4 |

| Inner PyC layer radius | 354.85e-4 |

| Silicon carbide layer radius | 389.85e-4 |

| Outer PyC layer radius | 429.85e-4 |

Heat is produced in the TRISO particles to yield a total power of 16.7 MWth. This heat is removed by helium flowing downwards through the coolant channels with a total mass flowrate of 9.775 kg/s, which is assumed to be uniformly distributed among the coolant channels. The outlet pressure is 7.1 MPa.

Heat Conduction Model

The MOOSE heat transfer module is used to solve for steady-state heat conduction,

(1)

where is the solid thermal conductivity, is the solid temperature, and is a volumetric heat source in the solid.

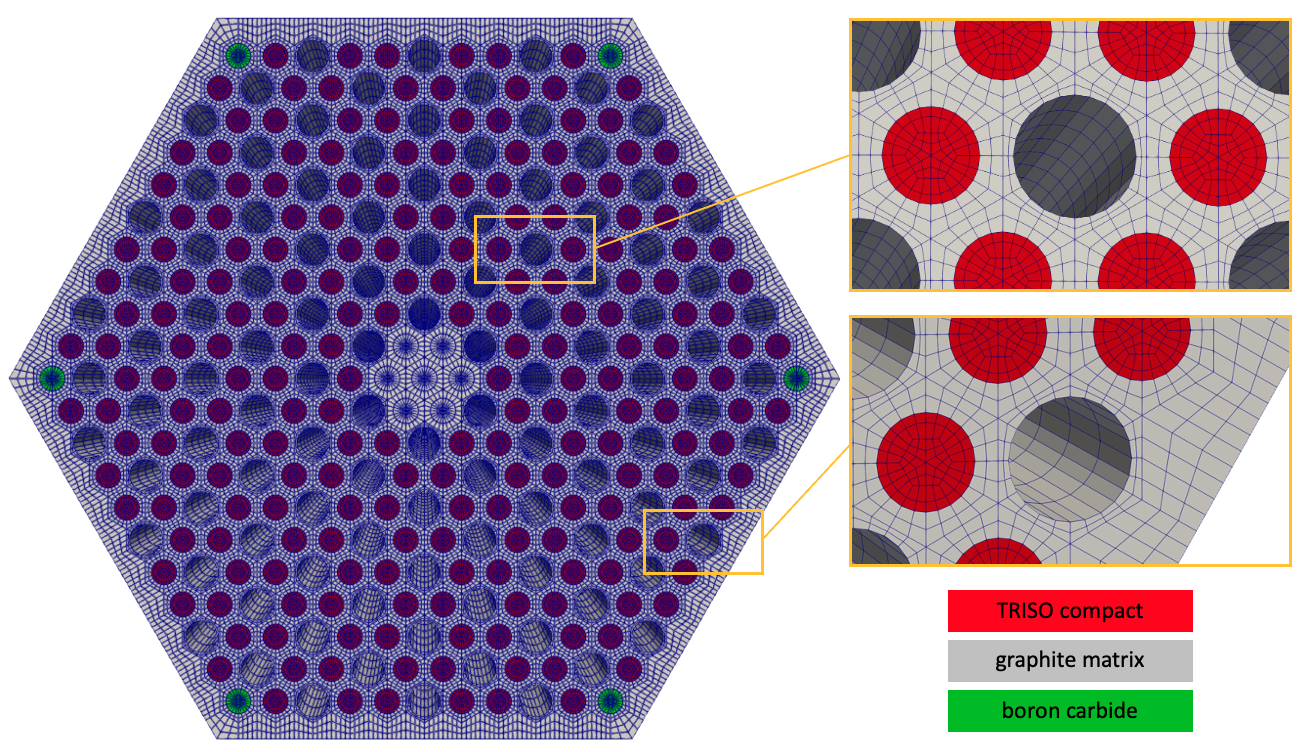

To greatly reduce meshing requirements, the TRISO particles are homogenized into the compact regions by volume-averaging material properties. The solid mesh is shown in Figure 2. The only sideset in the domain is the coolant channel surface, which is named fluid_solid_interface. The solid geometry uses a length unit of meters. The solid mesh is created using the MOOSE reactor module Shemon et al. (2021), which provides easy-to-use mesh generators to programmatically construct reactor core meshes as building blocks of bundle and pincell meshes.

Figure 2: Converged mesh for the solid heat conduction model (with 300 axial layers); to make the tutorial run faster, our mesh will only use 100 axial layers

The file used to generate the solid mesh is shown below. The mesh is created by first building pincell meshes for a fuel pin, a coolant pin, a poison pin, and a graphite "pin" (to represent the central graphite region). The pin meshes are then combined together into a bundle pattern and extruded.

!include common_input.i

n_layers = 100 # number of axial extrusion layers; for the converged case,

# we set this to 300 to get a finer mesh

[GlobalParams]

quad_center_elements = true

[]

[Mesh]

[fuel_pin]

type = PolygonConcentricCircleMeshGenerator

num_sides = 6

polygon_size = ${fparse fuel_to_coolant_distance / 2.0}

ring_radii = '${fparse 0.8 * compact_diameter / 2.0} ${fparse compact_diameter / 2.0}'

ring_intervals = '1 1'

num_sectors_per_side = '4 4 4 4 4 4'

ring_block_ids = '2 2'

ring_block_names = 'compacts compacts'

background_block_ids = '1'

background_block_names = 'graphite'

background_intervals = 2

[]

[coolant_pin]

type = PolygonConcentricCircleMeshGenerator

num_sides = 6

polygon_size = ${fparse fuel_to_coolant_distance / 2.0}

ring_radii = '${fparse channel_diameter / 2.0}'

ring_intervals = '2'

num_sectors_per_side = '4 4 4 4 4 4'

ring_block_ids = '101 101'

ring_block_names = 'coolant coolant'

background_block_ids = '1'

background_block_names = 'graphite'

interface_boundary_id_shift = 100

create_inward_interface_boundaries = true

background_intervals = 2

[]

[poison_pin]

type = PolygonConcentricCircleMeshGenerator

num_sides = 6

polygon_size = ${fparse fuel_to_coolant_distance / 2.0}

ring_radii = '${fparse compact_diameter / 2.0}'

ring_intervals = '2'

num_sectors_per_side = '4 4 4 4 4 4'

ring_block_ids = '4 4'

ring_block_names = 'poison poison'

background_block_ids = '1'

background_block_names = 'graphite'

background_intervals = 2

[]

[graphite_pin]

type = PolygonConcentricCircleMeshGenerator

num_sides = 6

polygon_size = ${fparse fuel_to_coolant_distance / 2.0}

ring_radii = '${fparse compact_diameter / 2.0}'

ring_intervals = '2'

num_sectors_per_side = '4 4 4 4 4 4'

ring_block_ids = '1 1'

ring_block_names = 'graphite graphite'

background_block_ids = '1'

background_block_names = 'graphite'

[]

[bundle]

type = PatternedHexMeshGenerator

inputs = 'fuel_pin coolant_pin poison_pin graphite_pin'

hexagon_size = ${fparse bundle_flat_to_flat / 2.0 + bundle_gap_width / 2.0}

pattern = '2 0 1 0 0 1 0 0 1 0 2;

0 1 0 0 1 0 0 1 0 0 1 0;

1 0 0 1 0 0 1 0 0 1 0 0 1;

0 0 1 0 0 1 0 0 1 0 0 1 0 0;

0 1 0 0 1 0 0 1 0 0 1 0 0 1 0;

1 0 0 1 0 0 1 0 0 1 0 0 1 0 0 1;

0 0 1 0 0 1 0 0 1 0 0 1 0 0 1 0 0;

0 1 0 0 1 0 0 1 0 0 1 0 0 1 0 0 1 0;

1 0 0 1 0 0 1 0 0 1 0 0 1 0 0 1 0 0 1;

0 0 1 0 0 1 0 0 1 3 3 1 0 0 1 0 0 1 0 0;

2 1 0 0 1 0 0 1 0 3 3 3 0 1 0 0 1 0 0 1 2;

0 0 1 0 0 1 0 0 1 3 3 1 0 0 1 0 0 1 0 0;

1 0 0 1 0 0 1 0 0 1 0 0 1 0 0 1 0 0 1;

0 1 0 0 1 0 0 1 0 0 1 0 0 1 0 0 1 0;

0 0 1 0 0 1 0 0 1 0 0 1 0 0 1 0 0;

1 0 0 1 0 0 1 0 0 1 0 0 1 0 0 1;

0 1 0 0 1 0 0 1 0 0 1 0 0 1 0;

0 0 1 0 0 1 0 0 1 0 0 1 0 0;

1 0 0 1 0 0 1 0 0 1 0 0 1;

0 1 0 0 1 0 0 1 0 0 1 0;

2 0 1 0 0 1 0 0 1 0 2'

rotate_angle = 0

background_block_id = '1'

[]

[extrude]

type = AdvancedExtruderGenerator

input = bundle

heights = ${height}

num_layers = ${n_layers}

direction = '0 0 1'

[]

[delete_coolant]

type = BlockDeletionGenerator

input = extrude

block = '101'

[]

[rename_coolant_sideset]

type = RenameBoundaryGenerator

input = delete_coolant

old_boundary = 102

new_boundary = 'fluid_solid_interface'

[]

construct_side_list_from_node_list = true

[]

# The following content is adding postprocessor(s) to check sideset areas.

# The reactor module is unfortunately quite brittle in its assignment of sideset

# IDs, so we want to be extra sure that any changes to sideset numbering are detected

# in our test suite.

You can create this mesh by running:

cardinal-opt -i solid_mesh.i --mesh-only

which will create a mesh named solid_mesh_in.e. Note that the above command takes advantage of a MOOSE feature for combining input files together by placing some common parameters used by the other applications into a file named common_input.i.

The temperature on the fluid-solid interface is provided by Thermal Hydraulics Module (THM), while the heat source is provided by OpenMC. Because MOOSE heat conduction will run first in the coupled case, the initial fluid temperature is set to an axial distribution given by bulk energy conservation () given the inlet temperature , mass flowrate , and fluid isobaric specific heat . The initial heat source distribution is assumed uniform in the radial direction with a sinusoidal dependence in the axial direction.

OpenMC Model

The OpenMC model is built using Constructive Solid Geometry (CSG). The TRISO positions are sampled using the Random Sequential Addition (RSA) algorithm in OpenMC. OpenMC's Python API is used to create the model with the script shown below. First, we define materials for the various regions. Next, we create a single TRISO particle universe consisting of the five layers of the particle and an infinite extent of graphite filling all other space. We then pack uniform-radius spheres into a cylindrical region representing a fuel compact, setting each sphere to be filled with the TRISO universe.

Next, we loop over 50 axial layers and create a unique hexagonal lattice for each layer. This hexagonal lattice defines the fuel assembly structure, and consists of four different universes:

A fuel pin plus surronding matrix (

f),A coolant channel plus surrounding matrix (

c),A boron carbide poision pin plus surrounding matrix (

p), andA homogeneous graphite hexagonal pincell to fill the "boundaries" and centermost region (

g).

In each layer we set up the lattice structure by listing the universes in each "ring" of the lattice, with ring0 being the centermost ring and ring11 being the outermost ring.

Recall that temperatures in OpenMC can be set directly on the cell, but that fluid densities can only be set on materials. For this reason, we need to create 108 unique coolant materials for each axial plane if we want to be able to set unique densities in each coolant channel region. Rather than creating 108 materials in a loop, we use the clone() feature in OpenMC to clone an existing coolant material 108 times per layer. This duplicates the material properties (densities and isotopic composition), but assigns a new ID that allows individual tracking of density. The Python script used to create the OpenMC model is shown below.

#!/bin/env python

from argparse import ArgumentParser

import math

import numpy as np

import matplotlib.pyplot as plt

import openmc

import sys

import os

# Get common input parameters shared by other physics

script_dir = os.path.dirname(__file__)

sys.path.append(script_dir)

import common_input as specs

def coolant_temp(t_in, t_out, l, z):

"""

Computes the coolant temperature based on an expected cosine power distribution

for a specified temperature rise. The total core temperature rise is governed

by energy conservation as dT = Q / m / Cp, where dT is the total core temperature

rise, Q is the total core power, m is the mass flowrate, and Cp is the fluid

isobaric specific heat. If you neglect axial heat conduction and assume steady

state, then the temperature rise in a layer of fluid i can be related to the

ratio of the power in that layer to the total power,

dT_i / dT = Q_i / Q. We assume here a sinusoidal power distribution to get

a reasonable estimate of an initial coolant temperature distribution.

Parameters

----------

t_in : float

Inlet temperature of the channel

t_out : float

Outlet temperature of the channel

l : float

Length of the channel

z : float or 1-D numpy.array

Axial position where the temperature will be computed

Returns

-------

float or 1-D numpy array of float depending on z

"""

dT = t_out - t_in

Q = 2 * l / math.pi

Qi = (l - l * np.cos(math.pi * z / l)) / math.pi

t = t_in + Qi / Q * dT

return t

def coolant_density(t):

"""

Computes the helium density (kg/m3) from temperature assuming a fixed operating pressure.

Parameters

----------

t : float

Fluid temperature

Returns

_______

float or 1-D numpy array of float depending on t

"""

p_in_bar = specs.outlet_P * 1.0e-5

return 48.14 * p_in_bar / (t + 0.4446 * p_in_bar / math.pow(t, 0.2))

# -------------- Unit Conversions: OpenMC requires cm -----------

m = 100.0

# estimate the outlet temperature using bulk energy conservation for steady state

coolant_outlet_temp = specs.power / specs.mdot / specs.fluid_Cp + specs.inlet_T

# geometry parameters

coolant_channel_diam = specs.channel_diameter * m

reactor_bottom = 0.0

reactor_height = specs.height * m

reactor_top = reactor_bottom + reactor_height

bundle_pitch = specs.bundle_flat_to_flat * m + specs.bundle_gap_width * m

cell_pitch = specs.fuel_to_coolant_distance * m

fuel_channel_diam = specs.compact_diameter * m

top_reflector_height = specs.top_reflector_thickness * m

bottom_reflector_height = specs.bottom_reflector_thickness * m

def assembly(n_ax_zones, n_inactive, n_active, add_entropy_mesh=False):

axial_section_height = reactor_height / n_ax_zones

# superimposed search lattice

triso_lattice_shape = (4, 4, int(axial_section_height / 0.05))

model = openmc.model.Model()

enrichment = 0.155 # U-235 enrichment (weight percent)

enrichment_234 = 2e-3 # U-234 enrichment (weight percent)

kernel_density = 10820 # fissile kernel density (kg/m3)

buffer_density = 1050 # buffer density (kg/m3)

PyC_density = 1900 # PyC density (kg/m3)

SiC_density = 3203 # SiC density (kg/m3)

matrix_density = 1700 # graphite matrix density (kg/m3)

# ----- uranium oxycarbide fuel ----- #

m_fuel = openmc.Material(name='fuel')

mass_234 = openmc.data.atomic_mass('U234')

mass_235 = openmc.data.atomic_mass('U235')

mass_238 = openmc.data.atomic_mass('U238')

n_234 = enrichment_234 / mass_234

n_235 = enrichment / mass_235

n_238 = (1.0 - enrichment - enrichment_234) / mass_238

total_n = n_234 + n_235 + n_238

m_fuel.add_nuclide('U234', n_234 / total_n)

m_fuel.add_nuclide('U235', n_235 / total_n)

m_fuel.add_nuclide('U238', n_238 / total_n)

m_fuel.add_element('C' , 1.50)

m_fuel.add_element('O' , 0.50)

m_fuel.set_density('kg/m3', kernel_density)

# ----- graphite buffer ----- #

m_graphite_c_buffer = openmc.Material(name='buffer')

m_graphite_c_buffer.add_element('C', 1.0)

m_graphite_c_buffer.add_s_alpha_beta('c_Graphite')

m_graphite_c_buffer.set_density('kg/m3', buffer_density)

# ----- pyrolitic carbon ----- #

m_graphite_pyc = openmc.Material(name='pyc')

m_graphite_pyc.add_element('C', 1.0)

m_graphite_pyc.add_s_alpha_beta('c_Graphite')

m_graphite_pyc.set_density('kg/m3', PyC_density)

# ----- silicon carbide ----- #

m_sic = openmc.Material(name='sic')

m_sic.add_element('C' , 1.0)

m_sic.add_element('Si', 1.0)

m_sic.set_density('kg/m3', SiC_density)

# ----- matrix graphite ----- #

m_graphite_matrix = openmc.Material(name='graphite moderator')

m_graphite_matrix.add_element('C', 1.0)

m_graphite_matrix.add_s_alpha_beta('c_Graphite')

m_graphite_matrix.set_density('kg/m3', matrix_density)

# ----- helium coolant ----- #

m_coolant = openmc.Material(name='Helium coolant')

m_coolant.add_element('He', 1.0, 'ao')

# we don't set density here because we'll set it as a function of temperature

m_b4c = openmc.Material(name='B4C')

enrichment_10 = specs.B10_enrichment

mass_10 = openmc.data.atomic_mass('B10')

mass_11 = openmc.data.atomic_mass('B11')

# number of atoms in one gram of boron mixture

n_10 = enrichment_10 / mass_10

n_11 = (1.0 - enrichment_10) / mass_11

total_n = n_10 + n_11

grams_10 = n_10 / total_n

grams_11 = n_11 / total_n

# now, figure out how much carbon needs to be in the poison to get

# an overall specified B10 weight percent

total_b10_weight_percent = specs.total_B10_wt_percent

total_mass = grams_10 / total_b10_weight_percent

carbon_mass = total_mass - grams_10 - grams_11

m_b4c.add_nuclide('B10', grams_10 / total_mass, 'wo')

m_b4c.add_nuclide('B11', grams_11 / total_mass, 'wo')

m_b4c.add_element('C', carbon_mass / total_mass, 'wo')

m_b4c.set_density('kg/m3', specs.B4C_density)

# reflector is 40 percent helium by volume (arbitrary assumption), with helium

# at the inlet conditions

rho = coolant_density(specs.inlet_T) # kg/m3

reflector_porosity = 0.40

n_helium = reflector_porosity * rho / 4.002602

n_carbon = (1.0 - reflector_porosity) * matrix_density / 12.0107

combined_density = rho * reflector_porosity + matrix_density * (1.0 - reflector_porosity)

m_reflector = openmc.Material(name='reflector')

m_reflector.add_element('He', n_helium / (n_helium + n_carbon))

m_reflector.add_element('C', n_carbon / (n_helium + n_carbon))

m_reflector.set_density('kg/m3', combined_density)

# TRISO particle

radius_pyc_outer = specs.oPyC_radius * m

s_fuel = openmc.Sphere(r=specs.kernel_radius*m)

s_c_buffer = openmc.Sphere(r=specs.buffer_radius*m)

s_pyc_inner = openmc.Sphere(r=specs.iPyC_radius*m)

s_sic = openmc.Sphere(r=specs.SiC_radius*m)

s_pyc_outer = openmc.Sphere(r=radius_pyc_outer)

c_triso_fuel = openmc.Cell(name='c_triso_fuel' , fill=m_fuel, region=-s_fuel)

c_triso_c_buffer = openmc.Cell(name='c_triso_c_buffer' , fill=m_graphite_c_buffer, region=+s_fuel & -s_c_buffer)

c_triso_pyc_inner = openmc.Cell(name='c_triso_pyc_inner', fill=m_graphite_pyc, region=+s_c_buffer & -s_pyc_inner)

c_triso_sic = openmc.Cell(name='c_triso_sic' , fill=m_sic, region=+s_pyc_inner & -s_sic)

c_triso_pyc_outer = openmc.Cell(name='c_triso_pyc_outer', fill=m_graphite_pyc, region=+s_sic & -s_pyc_outer)

c_triso_matrix = openmc.Cell(name='c_triso_matrix' , fill=m_graphite_matrix, region=+s_pyc_outer)

u_triso = openmc.Universe(cells=[c_triso_fuel, c_triso_c_buffer, c_triso_pyc_inner, c_triso_sic, c_triso_pyc_outer, c_triso_matrix])

# Channel surfaces

fuel_cyl = openmc.ZCylinder(r=0.5 * fuel_channel_diam)

coolant_cyl = openmc.ZCylinder(r=0.5 * coolant_channel_diam)

poison_cyl = openmc.ZCylinder(r=0.5 * fuel_channel_diam)

graphite_cyl = openmc.ZCylinder(r=0.5 * fuel_channel_diam)

# create a TRISO lattice for one axial section (to be used in the rest of the axial zones)

# center the TRISO region on the origin so it fills lattice cells appropriately

min_z = openmc.ZPlane(z0=-0.5 * axial_section_height)

max_z = openmc.ZPlane(z0=0.5 * axial_section_height)

# region in which TRISOs are generated

r_triso = -fuel_cyl & +min_z & -max_z

rand_spheres = openmc.model.pack_spheres(radius=radius_pyc_outer, region=r_triso, pf=specs.triso_pf, seed=1.0)

random_trisos = [openmc.model.TRISO(radius_pyc_outer, u_triso, i) for i in rand_spheres]

llc, urc = r_triso.bounding_box

pitch = (urc - llc) / triso_lattice_shape

# insert TRISOs into a lattice to accelerate point location queries

triso_lattice = openmc.model.create_triso_lattice(random_trisos, llc, pitch, triso_lattice_shape, m_graphite_matrix)

axial_coords = np.linspace(reactor_bottom, reactor_top, n_ax_zones + 1)

lattice_univs = []

bundle_univs = []

m_colors = {}

for z_min, z_max in zip(axial_coords[0:-1], axial_coords[1:]):

# use the middle of the axial section to compute the temperature and density

ax_pos = 0.5 * (z_min + z_max)

T = coolant_temp(specs.inlet_T, coolant_outlet_temp, reactor_height, ax_pos)

# create solid cells, which don't require us to clone materials in order to set temperatures

fuel_ch_cell = openmc.Cell(region=-fuel_cyl, fill=triso_lattice)

fuel_ch_cell.temperature = T

fuel_ch_matrix_cell = openmc.Cell(region=+fuel_cyl, fill=m_graphite_matrix)

fuel_ch_matrix_cell.temperature = T

poison_cell = openmc.Cell(region=-poison_cyl, fill=m_b4c)

poison_cell.temperature = T

poison_matrix_cell = openmc.Cell(region=+poison_cyl, fill=m_graphite_matrix)

poison_matrix_cell.temperature = T

graphite_cell = openmc.Cell(fill=m_graphite_matrix)

graphite_cell.temperature = T

coolant_matrix_cell = openmc.Cell(region=+coolant_cyl, fill=m_graphite_matrix)

coolant_matrix_cell.temperature = T

# create fluid cells, which require us to clone the material in order to be able to

# set unique densities

coolant_cell = openmc.Cell(region=-coolant_cyl, fill=m_coolant)

coolant_cell.fill = [m_coolant.clone() for i in range(specs.n_coolant_channels_per_block)]

for mat in range(len(coolant_cell.fill)):

m_colors[coolant_cell.fill[mat]] = 'red'

# Define a universe for each type of solid-only pin (fuel, poison, and graphite)

f = openmc.Universe(cells=[fuel_ch_cell, fuel_ch_matrix_cell])

p = openmc.Universe(cells=[poison_cell, poison_matrix_cell])

c = openmc.Universe(cells=[coolant_cell, coolant_matrix_cell])

g = openmc.Universe(cells=[graphite_cell])

d = [f] * 2

ring2 = ([f] + [c]) * 6

ring3 = ([c] + d) * 6

ring4 = (d + [c] + [f]) * 6

ring5 = ([f] + [c] + d + [c]) * 6

ring6 = ([c] + d + [c] + d) * 6

ring7 = (d + [c] + d + [c] + [f]) * 6

ring8 = ([f] + [c] + d + [c] + d + [c]) * 6

ring9 = ([c] + d + [c] + d + [c] + d) * 6

ring10 = ([p] + [f] + [c] + d + [c] + d + [c] + [f]) * 6

ring11 = [g] * 66

# inner two rings where there aren't any fuel/compact/poison pins

ring1 = [g] * 6

ring0 = [g]

lattice_univs.append([ring11, ring10, ring9, ring8, ring7, ring6, ring5, ring4, ring3, ring2, ring1, ring0])

# create a hexagonal lattice used in each axial zone to represent the cell

hex_lattice = openmc.HexLattice(name="Bundle cell lattice")

hex_lattice.orientation = 'x'

hex_lattice.center = (0.0, 0.0, 0.5 * (reactor_bottom + reactor_top))

hex_lattice.pitch = (cell_pitch, axial_section_height)

hex_lattice.universes = lattice_univs

hexagon_volume = reactor_height * math.sqrt(3) / 2.0 * bundle_pitch**2

coolant_channel_volume = math.pi * coolant_channel_diam**2 / 4.0 * reactor_height

graphite_outer_cell = openmc.Cell(fill=m_graphite_matrix)

graphite_outer_cell.temperature = T

inf_graphite_univ = openmc.Universe(cells=[graphite_outer_cell])

hex_lattice.outer = inf_graphite_univ

# create additional axial regions

axial_planes = [openmc.ZPlane(z0=coord) for coord in axial_coords]

# axial planes

min_z = axial_planes[0]

max_z = axial_planes[-1]

# fill the unit cell with the hex lattice

hex_prism = openmc.model.HexagonalPrism(bundle_pitch / math.sqrt(3.0), 'x', boundary_type='periodic')

outer_cell = openmc.Cell(region=-hex_prism & +min_z & -max_z, fill=hex_lattice)

# add the top and bottom reflector

top_refl_z = reactor_height + top_reflector_height

top_refl = openmc.ZPlane(z0=top_refl_z, boundary_type='vacuum')

bottom_refl_z = -bottom_reflector_height

bottom_refl = openmc.ZPlane(z0=bottom_refl_z, boundary_type='vacuum')

top_refl_cell = openmc.Cell(region=-hex_prism & +max_z & -top_refl, fill=m_reflector)

bottom_refl_cell = openmc.Cell(region=-hex_prism & -min_z & +bottom_refl, fill=m_reflector)

top_refl_cell.temperature = specs.inlet_T

bottom_refl_cell.temperature = coolant_outlet_temp

model.geometry = openmc.Geometry([outer_cell, top_refl_cell, bottom_refl_cell])

### Settings ###

settings = openmc.Settings()

settings.particles = 10000

settings.inactive = n_inactive

settings.batches = settings.inactive + n_active

settings.temperature['method'] = 'interpolation'

settings.temperature['range'] = (294.0, 1500.0)

l = bundle_pitch / math.sqrt(3.0)

lower_left = (-l, -l, reactor_bottom)

upper_right = (l, l, reactor_top)

source_dist = openmc.stats.Box(lower_left, upper_right, only_fissionable=True)

source = openmc.IndependentSource(space=source_dist)

settings.source = source

if (add_entropy_mesh):

entropy_mesh = openmc.RegularMesh()

entropy_mesh.lower_left = lower_left

entropy_mesh.upper_right = upper_right

entropy_mesh.dimension = (6, 6, 20)

settings.entropy_mesh = entropy_mesh

vol_calc = openmc.VolumeCalculation([outer_cell],

100_000_000, lower_left, upper_right)

settings.volume_calculations = [vol_calc]

model.settings = settings

m_colors[m_fuel] = 'palegreen'

m_colors[m_graphite_c_buffer] = 'sandybrown'

m_colors[m_graphite_pyc] = 'orange'

m_colors[m_sic] = 'yellow'

m_colors[m_graphite_matrix] = 'darkblue'

m_colors[m_b4c] = 'lightskyblue'

bundle_p_rounded = int(bundle_pitch)

plot1 = openmc.Plot()

plot1.filename = 'plot1'

plot1.width = (2 * bundle_pitch, 2 * axial_section_height)

plot1.basis = 'xz'

plot1.origin = (0.0, 0.0, reactor_height / 2.0)

plot1.pixels = (100 * 2 * bundle_p_rounded, int(100 * 3 * axial_section_height))

plot1.color_by = 'cell'

plot2 = openmc.Plot()

plot2.filename = 'plot2'

plot2.width = (1.5 * bundle_pitch, 1.5 * bundle_pitch)

plot2.basis = 'xy'

plot2.origin = (0.0, 0.0, axial_section_height / 4.0)

plot2.pixels = (500 * bundle_p_rounded, 500 * bundle_p_rounded)

plot2.color_by = 'material'

plot2.colors = m_colors

plot3 = openmc.Plot()

plot3.filename = 'plot3'

plot3.width = plot2.width

plot3.basis = plot2.basis

plot3.origin = plot2.origin

plot3.pixels = plot2.pixels

plot3.color_by = 'cell'

model.plots = openmc.Plots([plot1, plot2, plot3])

return model

def main():

ap = ArgumentParser()

ap.add_argument('-n', dest='n_axial', type=int, default=50,

help='Number of axial cell divisions')

ap.add_argument('-s', '--entropy', action='store_true',

help='Whether to add a Shannon entropy mesh')

ap.add_argument('-i', dest='n_inactive', type=int, default=500,

help='Number of inactive cycles')

ap.add_argument('-a', dest='n_active', type=int, default=2000,

help='Number of active cycles')

args = ap.parse_args()

model = assembly(args.n_axial, args.n_inactive, args.n_active, args.entropy)

model.export_to_xml()

if __name__ == "__main__":

main()

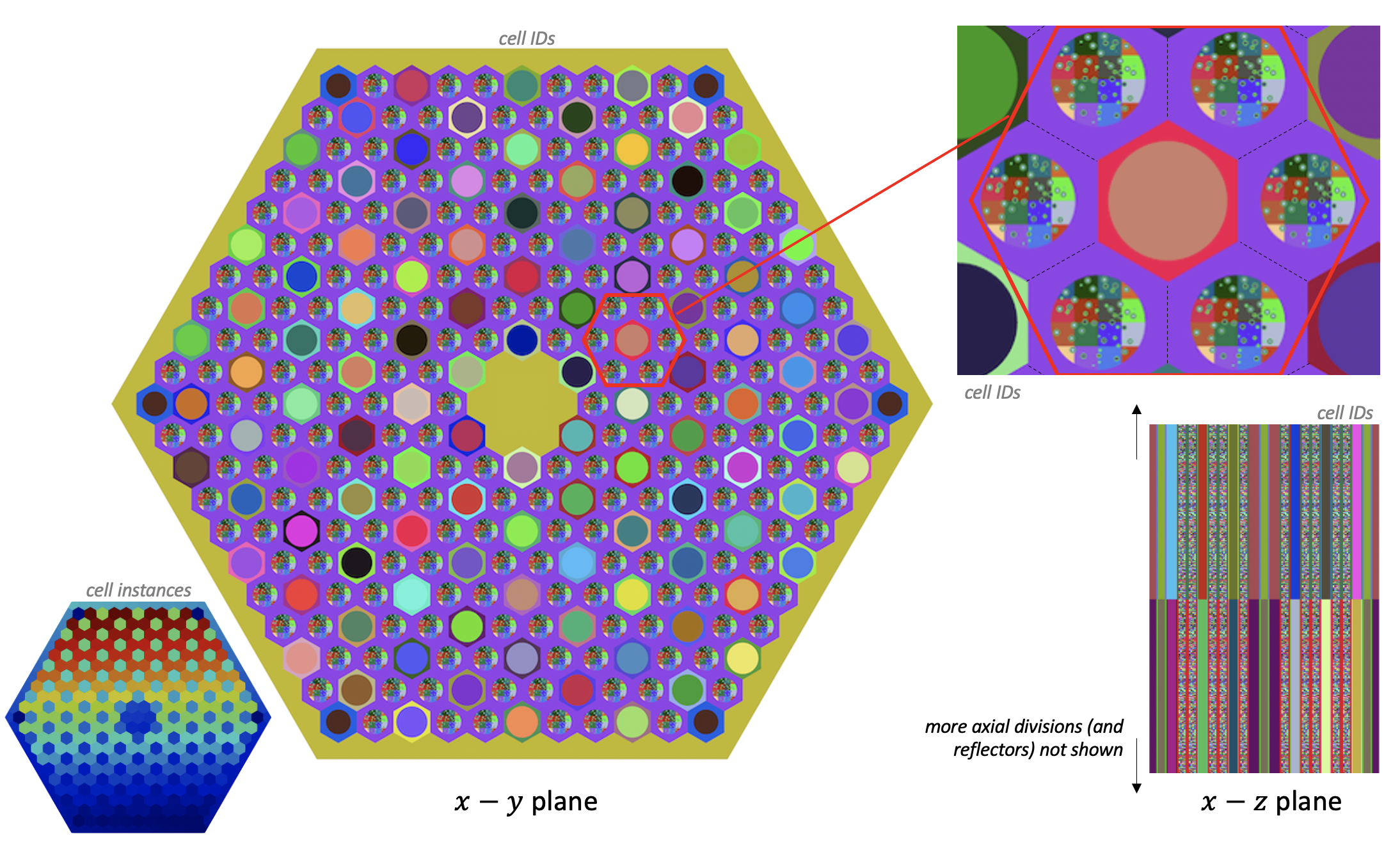

The level on which we will apply feedback from MOOSE is 1, because the geometry consists of a hexagonal lattice (level 0), and we want to apply individual cell feedback within that lattice (level 1). For the solid phase, this selection is equivalent to applying a single temperature (per compact and per layer) for a compact region - all TRISO particles and the surrounding matrix in each compact receives a uniform temperature. Finally, to accelerate the particle tracking, we:

Repeat the same TRISO universe in each axial layer and within each compact

Superimpose a Cartesian search lattice in the fuel channel regions.

The OpenMC geometry, colored by either cell ID or instance, is shown in Figure 3. Not shown are the axial reflectors on the top and bottom of the assembly. The lateral faces are periodic, while the top and bottom boundaries are vacuum. The Cartesian search lattice in the fuel compact regions is also visible in Figure 3.

Figure 3: OpenMC model, colored by cell ID or instance

Cardinal applies uniform temperature and density feedback to OpenMC for each unique cell ID instance combination. For this setup, OpenMC receives on each axial plane a total of 721 temperatures and 108 densities (one density per coolant channel). With references to the colors shown in Figure 3, the 721 cell temperatures correspond to:

The solid temperature is provided by the MOOSE heat transfer module, while the fluid temperature and density are provided by THM. Because we will run OpenMC second, the initial fluid temperature is set to the same initial condition that is imposed in the MOOSE solid model. The fluid density is then set using the ideal gas Equation of State (EOS) at a fixed pressure of 7.1 MPa given the imposed temperature, i.e. .

To create the XML files required to run OpenMC, run the script:

python assembly.py

You can also use the XML files checked in to the tutorials/gas_assembly directory; if you use these already-existing files, you will also need to download the geometry.xml file from Box; this file is large due to the saved TRISO geometry information.

THM Model

The Thermal Hydraulics Module (THM) solves for conservation of mass, momentum, and energy with 1-D area averages of the Navier-Stokes equations,

(2)

(3)

(4)

where is the coordinate along the flow length, is the channel cross-sectional area, is the fluid density, is the -component of velocity, is the average pressure on the curve boundary, is the fluid total energy, is the friction factor, is the wall heat transfer coefficient, is the heat transfer area density, is the wall temperature, and is the area average bulk fluid temperature.

In this tutorial, we use 50 elements for each channel. The mesh is constructed automatically within THM. To simplify the specification of material properties, the fluid geometry uses a length unit of meters. The heat flux imposed in the THM elements is obtained by area averaging the heat flux from the heat conduction model in 50 layers along the fluid-solid interface. For the reverse transfer, the wall temperature sent to MOOSE heat conduction is set to a uniform value along the fluid-solid interface according to a nearest-node mapping to the THM elements.

Because THM will run last in the coupled case, initial conditions are only required for pressure, fluid temperature, and velocity, which are set to uniform distributions.

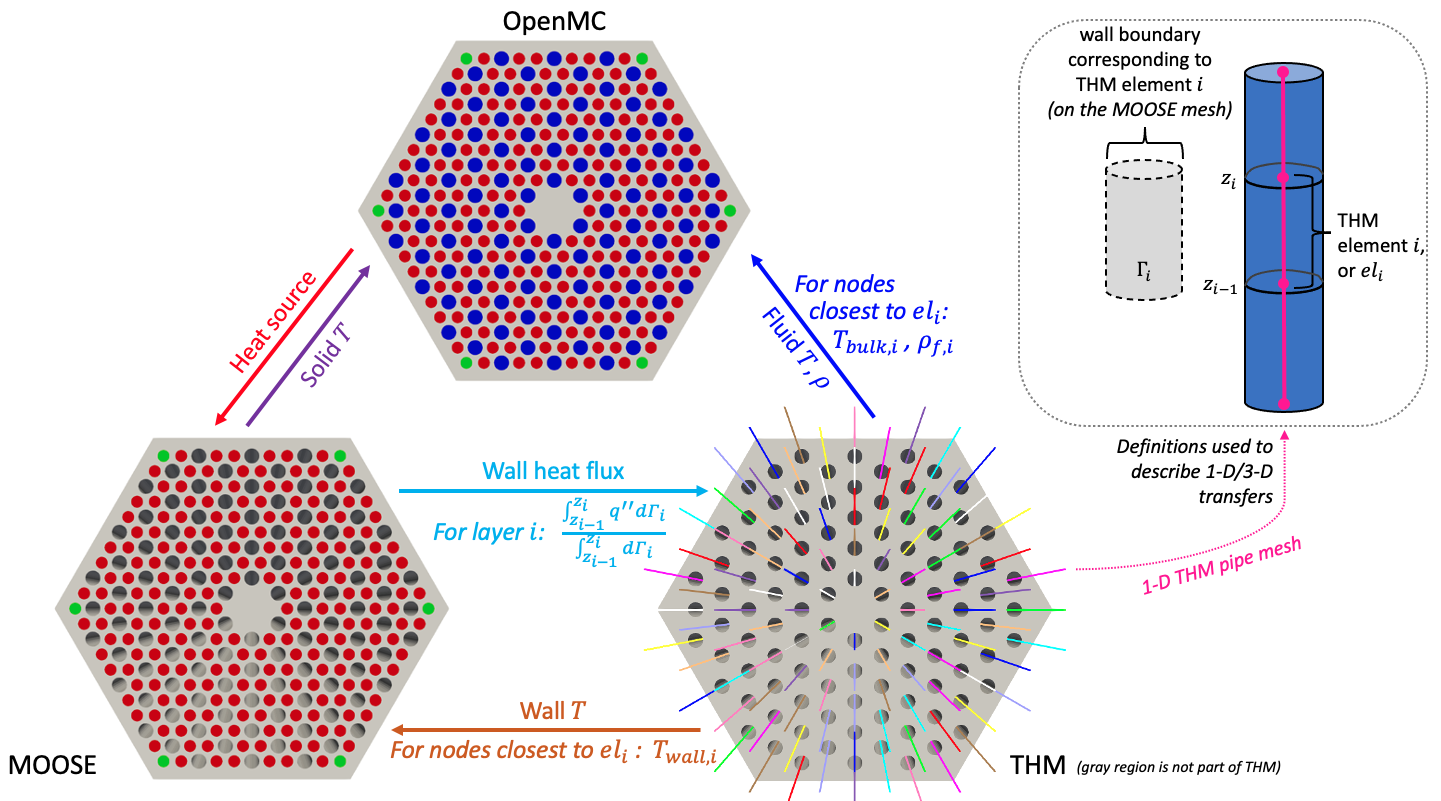

Multiphysics Coupling

A summary of the data transfers between the three applications is shown in Figure 4. The inset describes the 1-D/3-D data transfers with THM.

Figure 4: Summary of data transfers between OpenMC, MOOSE, and THM

Solid Input Files

The solid phase is solved with the MOOSE heat transfer module, and is described in the solid.i input. We define a number of constants at the beginning of the file and set up the mesh from a file.

!include common_input.i

# compute the volume fraction of each TRISO layer in a TRISO particle

# for use in computing average thermophysical properties

kernel_fraction = ${fparse kernel_radius^3 / oPyC_radius^3}

buffer_fraction = ${fparse (buffer_radius^3 - kernel_radius^3) / oPyC_radius^3}

ipyc_fraction = ${fparse (iPyC_radius^3 - buffer_radius^3) / oPyC_radius^3}

sic_fraction = ${fparse (SiC_radius^3 - iPyC_radius^3) / oPyC_radius^3}

opyc_fraction = ${fparse (oPyC_radius^3 - SiC_radius^3) / oPyC_radius^3}

[Mesh]

type = FileMesh

file = solid_mesh_in.e

[]

Next, we define the temperature variable, T, and specify the governing equations and boundary conditions we will apply.

[Variables<<<{"href": "../syntax/Variables/index.html"}>>>]

[T]

initial_condition<<<{"description": "Specifies a constant initial condition for this variable"}>>> = ${inlet_T}

[]

[]

[Kernels<<<{"href": "../syntax/Kernels/index.html"}>>>]

[diffusion]

type = HeatConduction<<<{"description": "Diffusive heat conduction term $-\\nabla\\cdot(k\\nabla T)$ of the thermal energy conservation equation", "href": "../source/kernels/HeatConduction.html"}>>>

variable<<<{"description": "The name of the variable that this residual object operates on"}>>> = T

[]

[source]

type = CoupledForce<<<{"description": "Implements a source term proportional to the value of a coupled variable. Weak form: $(\\psi_i, -\\sigma v)$.", "href": "../source/kernels/CoupledForce.html"}>>>

variable<<<{"description": "The name of the variable that this residual object operates on"}>>> = T

v<<<{"description": "The coupled variable which provides the force"}>>> = power

block<<<{"description": "The list of blocks (ids or names) that this object will be applied"}>>> = 'compacts'

[]

[]

[BCs<<<{"href": "../syntax/BCs/index.html"}>>>]

[pin_outer]

type = MatchedValueBC<<<{"description": "Implements a NodalBC which equates two different Variables' values on a specified boundary.", "href": "../source/bcs/MatchedValueBC.html"}>>>

variable<<<{"description": "The name of the variable that this residual object operates on"}>>> = T

v<<<{"description": "The variable whose value we are to match."}>>> = thm_temp

boundary<<<{"description": "The list of boundary IDs from the mesh where this object applies"}>>> = 'fluid_solid_interface'

[]

[]The MOOSE heat transfer module will receive power from OpenMC in the form of an AuxVariable, so we define a receiver variable for the fission power, as power. The MOOSE heat conduction module will also receive a fluid wall temperature from THM as another AuxVariable which we name thm_temp. Finally, the MOOSE heat transfer module will send the heat flux to THM, so we add a variable named flux that we will use to compute the heat flux using the DiffusionFluxAux auxiliary kernel.

[AuxVariables<<<{"href": "../syntax/AuxVariables/index.html"}>>>]

[thm_temp]

[]

[flux]

family<<<{"description": "Specifies the family of FE shape functions to use for this variable"}>>> = MONOMIAL

order<<<{"description": "Specifies the order of the FE shape function to use for this variable (additional orders not listed are allowed)"}>>> = CONSTANT

[]

[power]

family<<<{"description": "Specifies the family of FE shape functions to use for this variable"}>>> = MONOMIAL

order<<<{"description": "Specifies the order of the FE shape function to use for this variable (additional orders not listed are allowed)"}>>> = CONSTANT

[]

[]

[AuxKernels<<<{"href": "../syntax/AuxKernels/index.html"}>>>]

[flux]

type = DiffusionFluxAux<<<{"description": "Compute components of flux vector for diffusion problems $(\\vec{J} = -D \\nabla C)$.", "href": "../source/auxkernels/DiffusionFluxAux.html"}>>>

diffusion_variable<<<{"description": "The name of the variable"}>>> = T

component<<<{"description": "The desired component of flux."}>>> = normal

diffusivity<<<{"description": "The name of the diffusivity material property that will be used in the flux computation."}>>> = thermal_conductivity

variable<<<{"description": "The name of the variable that this object applies to"}>>> = flux

boundary<<<{"description": "The list of boundaries (ids or names) from the mesh where this object applies"}>>> = 'fluid_solid_interface'

[]

[]We use functions to define the thermal conductivities. The material properties for the TRISO compacts are taken as volume averages of the various constituent materials. We will evaluate the thermal conductivity for the boron carbide as a function of temperature by using t (which usually is interpeted as time) as a variable to represent temperature. This is syntax supported by the HeatConductionMaterials used to apply these functions to the thermal conductivity.

[Functions<<<{"href": "../syntax/Functions/index.html"}>>>]

[k_graphite]

type = ParsedFunction<<<{"description": "Function created by parsing a string", "href": "../source/functions/MooseParsedFunction.html"}>>>

expression<<<{"description": "The user defined function."}>>> = '${matrix_k}'

[]

[k_TRISO]

type = ParsedFunction<<<{"description": "Function created by parsing a string", "href": "../source/functions/MooseParsedFunction.html"}>>>

expression<<<{"description": "The user defined function."}>>> = '${kernel_fraction} * ${kernel_k} + ${buffer_fraction} * ${buffer_k} + ${fparse ipyc_fraction + opyc_fraction} * ${PyC_k} + ${sic_fraction} * ${SiC_k}'

[]

[k_compacts]

type = ParsedFunction<<<{"description": "Function created by parsing a string", "href": "../source/functions/MooseParsedFunction.html"}>>>

expression<<<{"description": "The user defined function."}>>> = '${triso_pf} * k_TRISO + ${fparse 1.0 - triso_pf} * k_graphite'

symbol_names<<<{"description": "Symbols (excluding t,x,y,z) that are bound to the values provided by the corresponding items in the vals vector."}>>> = 'k_TRISO k_graphite'

symbol_values<<<{"description": "Constant numeric values, postprocessor names, function names, and scalar variables corresponding to the symbols in symbol_names."}>>> = 'k_TRISO k_graphite'

[]

[k_b4c]

type = ParsedFunction<<<{"description": "Function created by parsing a string", "href": "../source/functions/MooseParsedFunction.html"}>>>

expression<<<{"description": "The user defined function."}>>> = '5.096154e-6 * t - 1.952360e-2 * t + 2.558435e1'

[]

[]

[Materials<<<{"href": "../syntax/Materials/index.html"}>>>]

[graphite]

type = HeatConductionMaterial<<<{"description": "General-purpose material model for heat conduction", "href": "../source/materials/HeatConductionMaterial.html"}>>>

thermal_conductivity_temperature_function<<<{"description": "Thermal conductivity as a function of temperature."}>>> = k_graphite

temp<<<{"description": "Coupled Temperature"}>>> = T

block<<<{"description": "The list of blocks (ids or names) that this object will be applied"}>>> = 'graphite'

[]

[compacts]

type = HeatConductionMaterial<<<{"description": "General-purpose material model for heat conduction", "href": "../source/materials/HeatConductionMaterial.html"}>>>

thermal_conductivity_temperature_function<<<{"description": "Thermal conductivity as a function of temperature."}>>> = k_compacts

temp<<<{"description": "Coupled Temperature"}>>> = T

block<<<{"description": "The list of blocks (ids or names) that this object will be applied"}>>> = 'compacts'

[]

[poison]

type = HeatConductionMaterial<<<{"description": "General-purpose material model for heat conduction", "href": "../source/materials/HeatConductionMaterial.html"}>>>

thermal_conductivity_temperature_function<<<{"description": "Thermal conductivity as a function of temperature."}>>> = k_b4c

temp<<<{"description": "Coupled Temperature"}>>> = T

block<<<{"description": "The list of blocks (ids or names) that this object will be applied"}>>> = 'poison'

[]

[]We define a number of postprocessors for querying the solution as well as for normalizing the fission power and heat flux, to be described at greater length in Neutronics Input Files .

[Postprocessors<<<{"href": "../syntax/Postprocessors/index.html"}>>>]

[flux_integral]

# evaluate the total heat flux for normalization

type = SideDiffusiveFluxIntegral<<<{"description": "Computes the integral of the diffusive flux over the specified boundary", "href": "../source/postprocessors/SideDiffusiveFluxIntegral.html"}>>>

diffusivity<<<{"description": "The name of the diffusivity material property that will be used in the flux computation. This must be provided if the variable is of finite element type"}>>> = thermal_conductivity

variable<<<{"description": "The name of the variable which this postprocessor integrates"}>>> = T

boundary<<<{"description": "The list of boundary IDs from the mesh where this object applies"}>>> = 'fluid_solid_interface'

[]

[max_fuel_T]

type = ElementExtremeValue<<<{"description": "Finds either the min or max elemental value of a variable over the domain.", "href": "../source/postprocessors/ElementExtremeValue.html"}>>>

variable<<<{"description": "The name of the variable that this postprocessor operates on"}>>> = T

value_type<<<{"description": "Type of extreme value to return. 'max' returns the maximum value. 'min' returns the minimum value. 'max_abs' returns the maximum of the absolute value."}>>> = max

block<<<{"description": "The list of blocks (ids or names) that this object will be applied"}>>> = 'compacts'

[]

[max_block_T]

type = ElementExtremeValue<<<{"description": "Finds either the min or max elemental value of a variable over the domain.", "href": "../source/postprocessors/ElementExtremeValue.html"}>>>

variable<<<{"description": "The name of the variable that this postprocessor operates on"}>>> = T

value_type<<<{"description": "Type of extreme value to return. 'max' returns the maximum value. 'min' returns the minimum value. 'max_abs' returns the maximum of the absolute value."}>>> = max

block<<<{"description": "The list of blocks (ids or names) that this object will be applied"}>>> = 'graphite'

[]

[power]

# evaluate the total power for normalization

type = ElementIntegralVariablePostprocessor<<<{"description": "Computes a volume integral of the specified variable", "href": "../source/postprocessors/ElementIntegralVariablePostprocessor.html"}>>>

variable<<<{"description": "The name of the variable that this object operates on"}>>> = power

block<<<{"description": "The list of blocks (ids or names) that this object will be applied"}>>> = 'compacts'

execute_on<<<{"description": "The list of flag(s) indicating when this object should be executed. For a description of each flag, see https://mooseframework.inl.gov/source/interfaces/SetupInterface.html."}>>> = 'transfer'

[]

[]For visualization purposes only, we add LayeredAverages for the fuel and block temperatures. These will average the temperature in layers oriented in the direction, which we will use for plotting axial temperature distributions. We output the results of these userobjects to CSV using SpatialUserObjectVectorPostprocessors and by setting csv = true in the output.

[UserObjects<<<{"href": "../syntax/UserObjects/index.html"}>>>]

[average_fuel_axial]

type = LayeredAverage<<<{"description": "Computes averages of variables over layers", "href": "../source/userobjects/LayeredAverage.html"}>>>

variable<<<{"description": "The name of the variable that this object operates on"}>>> = T

direction<<<{"description": "The direction of the layers."}>>> = z

num_layers<<<{"description": "The number of layers."}>>> = ${num_layers_for_plots}

block<<<{"description": "The list of block ids (SubdomainID) that this object will be applied"}>>> = 'compacts'

[]

[average_block_axial]

type = LayeredAverage<<<{"description": "Computes averages of variables over layers", "href": "../source/userobjects/LayeredAverage.html"}>>>

variable<<<{"description": "The name of the variable that this object operates on"}>>> = T

direction<<<{"description": "The direction of the layers."}>>> = z

num_layers<<<{"description": "The number of layers."}>>> = ${num_layers_for_plots}

block<<<{"description": "The list of block ids (SubdomainID) that this object will be applied"}>>> = 'graphite'

[]

[]

[VectorPostprocessors<<<{"href": "../syntax/VectorPostprocessors/index.html"}>>>]

[fuel_axial_avg]

type = SpatialUserObjectVectorPostprocessor<<<{"description": "Outputs the values of a spatial user object in the order of the specified spatial points", "href": "../source/vectorpostprocessors/SpatialUserObjectVectorPostprocessor.html"}>>>

userobject<<<{"description": "The userobject whose values are to be reported"}>>> = average_fuel_axial

[]

[block_axial_avg]

type = SpatialUserObjectVectorPostprocessor<<<{"description": "Outputs the values of a spatial user object in the order of the specified spatial points", "href": "../source/vectorpostprocessors/SpatialUserObjectVectorPostprocessor.html"}>>>

userobject<<<{"description": "The userobject whose values are to be reported"}>>> = average_block_axial

[]

[]

[Outputs<<<{"href": "../syntax/Outputs/index.html"}>>>]

exodus<<<{"description": "Output the results using the default settings for Exodus output."}>>> = true

csv<<<{"description": "Output the scalar variable and postprocessors to a *.csv file using the default CSV output."}>>> = true

print_linear_residuals<<<{"description": "Enable printing of linear residuals to the screen (Console)"}>>> = false

[]Finally, we specify a Transient executioner. Because there are no time-dependent kernels in this input file, this is equivalent in practice to using a Steady executioner, but allows you to potentially sub-cycle the MOOSE heat conduction solve relative to the OpenMC solve (such as if you wanted to converge the CHT fully inbetween data exchanges with OpenMC).

[Executioner<<<{"href": "../syntax/Executioner/index.html"}>>>]

type = Transient

nl_abs_tol = 1e-5

nl_rel_tol = 1e-16

petsc_options_value = 'hypre boomeramg'

petsc_options_iname = '-pc_type -pc_hypre_type'

[]Fluid Input Files

The fluid phase is solved with THM, and is described in the thm.i input. This input file is built using syntax specific to THM - we will only briefly cover this syntax, and instead refer users to the THM documentation for more information. First we define a number of constants at the beginning of the file and apply some global settings. We set the initial conditions for pressure, velocity, and temperature and indicate the fluid EOS object using IdealGasFluidProperties.

!include common_input.i

mdot_single_channel = ${fparse 117.3 / 12 / 108} # individual coolant channel fluid mass flowrate (kg/s)

num_layers_for_THM = 50 # number of elements in the THM model; for the converged case,

# we set this to 150

[GlobalParams]

initial_p = ${outlet_P}

initial_T = ${inlet_T}

initial_vel = ${fparse mdot_single_channel / outlet_P / 8.3144598 * 4.0e-3 / inlet_T / (pi * channel_diameter * channel_diameter / 4.0)}

rdg_slope_reconstruction = full

closures = none

fp = helium

[]

[Closures]

[none]

type = WallTemperature1PhaseClosures

[]

[]

[FluidProperties]

[helium]

type = IdealGasFluidProperties

molar_mass = 4e-3

gamma = 1.668282 # should correspond to Cp = 5189 J/kg/K

k = 0.2556

mu = 3.22639e-5

[]

[]

Next, we define the "components" in the domain. These components essentially consist of the physics equations and boundary conditions solved by THM, but expressed in THM-specific syntax. These components define single-phase flow in a pipe, an inlet mass flowrate boundary condition, an outlet pressure boundary condition, and heat transfer to the pipe wall.

[Components<<<{"href": "../syntax/Components/index.html"}>>>]

[channel]

type = FlowChannel1Phase<<<{"description": "1-phase 1D flow channel", "href": "../source/components/FlowChannel1Phase.html"}>>>

position<<<{"description": "Start position of axis in 3-D space [m]"}>>> = '0 0 ${height}'

orientation<<<{"description": "Direction of flow channel from start position to end position (no need to normalize). For curved flow channels, it is the (tangent) direction at the start position."}>>> = '0 0 -1'

A<<<{"description": "Area of the flow channel, can be a constant or a function"}>>> = '${fparse pi * channel_diameter * channel_diameter / 4}'

D_h<<<{"description": "Hydraulic diameter [m]"}>>> = ${channel_diameter}

length<<<{"description": "Length of each axial section [m]"}>>> = ${height}

n_elems<<<{"description": "Number of elements in each axial section"}>>> = ${num_layers_for_THM}

[]

[inlet]

type = InletMassFlowRateTemperature1Phase<<<{"description": "Boundary condition with prescribed mass flow rate and temperature for 1-phase flow channels.", "href": "../source/components/InletMassFlowRateTemperature1Phase.html"}>>>

input<<<{"description": "Name of the input"}>>> = 'channel:in'

m_dot<<<{"description": "Prescribed mass flow rate [kg/s]"}>>> = ${mdot_single_channel}

T<<<{"description": "Prescribed temperature [K]"}>>> = ${inlet_T}

[]

[outlet]

type = Outlet1Phase<<<{"description": "Boundary condition with prescribed pressure for 1-phase flow channels.", "href": "../source/components/Outlet1Phase.html"}>>>

input<<<{"description": "Name of the input"}>>> = 'channel:out'

p<<<{"description": "Prescribed pressure [Pa]"}>>> = ${outlet_P}

[]

[ht_ext]

type = HeatTransferFromExternalAppHeatFlux1Phase<<<{"description": "Heat transfer specified by heat flux provided by an external application going into 1-phase flow channel.", "href": "../source/components/HeatTransferFromExternalAppHeatFlux1Phase.html"}>>>

flow_channel<<<{"description": "Name of flow channel component to connect to"}>>> = channel

P_hf<<<{"description": "Heat flux perimeter [m]"}>>> = '${fparse channel_diameter * pi}'

[]

[]Associated with these components are a number of closures, defined as materials. We set up the Churchill correlation for the friction factor and the Dittus-Boelter correlation for the convective heat transfer coefficient. Additional materials are created to represent dimensionless numbers and other auxiliary terms, such as the wall temperature. As can be seen here, the Material system is not always used to represent quantities traditionally thought of as "material properties."

[Materials<<<{"href": "../syntax/Materials/index.html"}>>>]

# wall friction closure

[f_mat]

type = ADWallFrictionChurchillMaterial<<<{"description": "Computes the Darcy friction factor using the Churchill correlation.", "href": "../source/materials/ADWallFrictionChurchillMaterial.html"}>>>

block<<<{"description": "The list of blocks (ids or names) that this object will be applied"}>>> = channel

D_h<<<{"description": "hydraulic diameter"}>>> = D_h

f_D<<<{"description": "Darcy friction factor material property"}>>> = f_D

vel<<<{"description": "x-component of the velocity"}>>> = vel

rho<<<{"description": "Density"}>>> = rho

mu<<<{"description": "Dynamic viscosity material property"}>>> = mu

[]

# Wall heat transfer closure (all important is in Nu_mat)

[Re_mat]

type = ADReynoldsNumberMaterial<<<{"description": "Computes Reynolds number as a material property", "href": "../source/materials/ADReynoldsNumberMaterial.html"}>>>

block<<<{"description": "The list of blocks (ids or names) that this object will be applied"}>>> = channel

Re<<<{"description": "Reynolds number property name"}>>> = Re

D_h<<<{"description": "Hydraulic diameter"}>>> = D_h

mu<<<{"description": "Dynamic viscosity of the phase"}>>> = mu

vel<<<{"description": "Velocity of the phase"}>>> = vel

rho<<<{"description": "Density of the phase"}>>> = rho

[]

[Pr_mat]

type = ADPrandtlNumberMaterial<<<{"description": "Computes Prandtl number as material property", "href": "../source/materials/ADPrandtlNumberMaterial.html"}>>>

block<<<{"description": "The list of blocks (ids or names) that this object will be applied"}>>> = channel

cp<<<{"description": "Constant-pressure specific heat"}>>> = cp

mu<<<{"description": "Dynamic viscosity"}>>> = mu

k<<<{"description": "Thermal conductivity"}>>> = k

[]

[Nu_mat]

type = ADParsedMaterial<<<{"description": "Parsed expression Material.", "href": "../source/materials/ParsedMaterial.html"}>>>

block<<<{"description": "The list of blocks (ids or names) that this object will be applied"}>>> = channel

# Dittus-Boelter

expression<<<{"description": "Parsed function (see FParser) expression for the parsed material"}>>> = '0.022 * pow(Re, 0.8) * pow(Pr, 0.4)'

property_name<<<{"description": "Name of the parsed material property"}>>> = 'Nu'

material_property_names<<<{"description": "Vector of material properties used in the parsed function"}>>> = 'Re Pr'

[]

[Hw_mat]

type = ADConvectiveHeatTransferCoefficientMaterial<<<{"description": "Computes convective heat transfer coefficient from Nusselt number", "href": "../source/materials/ADConvectiveHeatTransferCoefficientMaterial.html"}>>>

block<<<{"description": "The list of blocks (ids or names) that this object will be applied"}>>> = channel

D_h<<<{"description": "Hydraulic diameter"}>>> = D_h

Nu<<<{"description": "Nusselt number"}>>> = Nu

k<<<{"description": "Thermal conductivity"}>>> = k

[]

[T_wall]

type = ADTemperatureWall3EqnMaterial<<<{"description": "Computes the wall temperature from the fluid temperature, the heat flux and the heat transfer coefficient", "href": "../source/materials/ADTemperatureWall3EqnMaterial.html"}>>>

Hw<<<{"description": "Heat transfer coefficient"}>>> = Hw

T<<<{"description": "Fluid temperature"}>>> = T

q_wall<<<{"description": "Wall heat flux"}>>> = q_wall

[]

[]THM computes the wall temperature to apply a boundary condition in the MOOSE heat transfer module. To convert the T_wall material into an auxiliary variable, we use the ADMaterialRealAux.

[AuxVariables<<<{"href": "../syntax/AuxVariables/index.html"}>>>]

[T_wall]

family<<<{"description": "Specifies the family of FE shape functions to use for this variable"}>>> = MONOMIAL

order<<<{"description": "Specifies the order of the FE shape function to use for this variable (additional orders not listed are allowed)"}>>> = CONSTANT

[]

[]

[AuxKernels<<<{"href": "../syntax/AuxKernels/index.html"}>>>]

[Tw_aux]

type = ADMaterialRealAux<<<{"description": "Outputs element volume-averaged material properties", "href": "../source/auxkernels/MaterialRealAux.html"}>>>

block<<<{"description": "The list of blocks (ids or names) that this object will be applied"}>>> = channel

variable<<<{"description": "The name of the variable that this object applies to"}>>> = T_wall

property<<<{"description": "The material property name."}>>> = T_wall

[]

[]Finally, we set the preconditioner, a Transient executioner, and set an Exodus output. The steady_state_detection and steady_state_tolerance parameters will automatically terminate the THM solution once the relative change in the solution is less than .

[Preconditioning<<<{"href": "../syntax/Preconditioning/index.html"}>>>]

[pc]

type = SMP<<<{"description": "Single matrix preconditioner (SMP) builds a preconditioner using user defined off-diagonal parts of the Jacobian.", "href": "../source/preconditioners/SingleMatrixPreconditioner.html"}>>>

full<<<{"description": "Set to true if you want the full set of couplings between variables simply for convenience so you don't have to set every off_diag_row and off_diag_column combination."}>>> = true

[]

[]

[Executioner<<<{"href": "../syntax/Executioner/index.html"}>>>]

type = Transient

dt = 0.1

start_time = 0

steady_state_detection = true

steady_state_tolerance = 1e-08

nl_rel_tol = 1e-5

nl_abs_tol = 1e-6

petsc_options_iname = '-pc_type'

petsc_options_value = 'lu'

solve_type = NEWTON

line_search = basic

[]

[Outputs<<<{"href": "../syntax/Outputs/index.html"}>>>]

exodus<<<{"description": "Output the results using the default settings for Exodus output."}>>> = true

print_linear_residuals<<<{"description": "Enable printing of linear residuals to the screen (Console)"}>>> = false

[console]

type = Console<<<{"description": "Object for screen output.", "href": "../source/outputs/Console.html"}>>>

outlier_variable_norms<<<{"description": "If true, outlier variable norms will be printed after each solve"}>>> = false

[]

[]As you may notice, this THM input file only models a single coolant flow channel. We will leverage a feature in MOOSE that allows a single application to be repeated multiple times throughout a main application without having to merge input files or perform other transformations. We will run OpenMC as the main application; the syntax needed to achieve this setup is covered next.

Neutronics Input Files

The neutronics physics is solved with OpenMC over the entire domain. The OpenMC wrapping is described in the openmc.i file. We begin by defining a number of constants and by setting up the mesh mirror on which OpenMC will receive temperature and density from the coupled applications, and on which OpenMC will write the fission heat source. Because the coupled MOOSE applications use length units of meters, the mesh mirror must also be in units of meters in order to obtain correct data transfers. For simplicity, we use the same solid mesh as used by the solid heat conduction solution, but this is not required. For the fluid region, we use MOOSE mesh generators to construct a mesh for a single coolant channel, and then repeat it for the 108 coolant channels.

!include common_input.i

num_layers_for_THM = 50 # number of elements in the THM model; for the converged

# case, we set this to 150

[Mesh]

# mesh mirror for the solid regions

[solid]

type = FileMeshGenerator

file = solid_mesh_in.e

[]

# create a mesh for a single coolant channel; because we will receive uniform

# temperatures and densities from THM on each x-y plane, we can use a very coarse

# mesh in the radial direction

[coolant_face]

type = AnnularMeshGenerator

nr = 1

nt = 8

rmin = 0.0

rmax = ${fparse channel_diameter / 2.0}

[]

[extrude]

type = AdvancedExtruderGenerator

input = coolant_face

num_layers = ${num_layers_for_THM}

direction = '0 0 1'

heights = '${height}'

top_boundary = '300' # inlet

bottom_boundary = '400' # outlet

[]

[rename]

type = RenameBlockGenerator

input = extrude

old_block = '1'

new_block = '101'

[]

# repeat the coolant channels and then combine together to get a combined mesh mirror

[repeat]

type = CombinerGenerator

inputs = rename

positions_file = coolant_channel_positions.txt

[]

[add]

type = CombinerGenerator

inputs = 'solid repeat'

[]

[]

Before progressing further, we first need to describe the multiapp structure connecting OpenMC, MOOSE heat conduction, and THM. We set the main application to OpenMC, and will have both MOOSE heat conduction and THM as "sibling" sub-applications.

At the time of writing, the MOOSE framework does not support "sibling" multiapp transfers, meaning that the data to be communicated between MOOSE heat conduction and THM (the heat flux and wall temperature data transfers in Figure 4) must go "up a level" to their common main application. This has since been relaxed.

Therefore, we will see in the OpenMC input file information related to data transfers between MOOSE heat conduction and THM. The auxiliary variables defined for the OpenMC model are shown below.

[AuxVariables<<<{"href": "../syntax/AuxVariables/index.html"}>>>]

[material_id]

family<<<{"description": "Specifies the family of FE shape functions to use for this variable"}>>> = MONOMIAL

order<<<{"description": "Specifies the order of the FE shape function to use for this variable (additional orders not listed are allowed)"}>>> = CONSTANT

[]

[cell_temperature]

family<<<{"description": "Specifies the family of FE shape functions to use for this variable"}>>> = MONOMIAL

order<<<{"description": "Specifies the order of the FE shape function to use for this variable (additional orders not listed are allowed)"}>>> = CONSTANT

[]

[cell_density]

family<<<{"description": "Specifies the family of FE shape functions to use for this variable"}>>> = MONOMIAL

order<<<{"description": "Specifies the order of the FE shape function to use for this variable (additional orders not listed are allowed)"}>>> = CONSTANT

[]

[thm_temp_wall]

block = '101'

[]

[flux]

[]

# just for postprocessing purposes

[thm_pressure]

block = '101'

[]

[thm_velocity]

block = '101'

[]

[z]

family<<<{"description": "Specifies the family of FE shape functions to use for this variable"}>>> = MONOMIAL

order<<<{"description": "Specifies the order of the FE shape function to use for this variable (additional orders not listed are allowed)"}>>> = CONSTANT

block = 'compacts'

[]

[]

[AuxKernels<<<{"href": "../syntax/AuxKernels/index.html"}>>>]

[material_id]

type = CellMaterialIDAux<<<{"description": "OpenMC fluid material ID, mapped to each MOOSE element", "href": "../source/auxkernels/CellMaterialIDAux.html"}>>>

variable<<<{"description": "The name of the variable that this object applies to"}>>> = material_id

[]

[cell_temperature]

type = CellTemperatureAux<<<{"description": "OpenMC cell temperature (K), mapped to each MOOSE element", "href": "../source/auxkernels/CellTemperatureAux.html"}>>>

variable<<<{"description": "The name of the variable that this object applies to"}>>> = cell_temperature

[]

[cell_density]

type = CellDensityAux<<<{"description": "OpenMC fluid density (kg/m$^3$), mapped to each MOOSE element", "href": "../source/auxkernels/CellDensityAux.html"}>>>

variable<<<{"description": "The name of the variable that this object applies to"}>>> = cell_density

[]

[density]

type = FluidDensityAux<<<{"description": "Computes density from pressure and temperature", "href": "../source/auxkernels/FluidDensityAux.html"}>>>

variable<<<{"description": "The name of the variable that this object applies to"}>>> = density

p<<<{"description": "Pressure"}>>> = ${outlet_P}

T<<<{"description": "Temperature"}>>> = thm_temp

fp<<<{"description": "The name of the user object for fluid properties"}>>> = helium

execute_on<<<{"description": "The list of flag(s) indicating when this object should be executed. For a description of each flag, see https://mooseframework.inl.gov/source/interfaces/SetupInterface.html."}>>> = 'timestep_begin linear'

[]

[z]

type = ParsedAux<<<{"description": "Sets a field variable value to the evaluation of a parsed expression.", "href": "../source/auxkernels/ParsedAux.html"}>>>

variable<<<{"description": "The name of the variable that this object applies to"}>>> = z

use_xyzt<<<{"description": "Make coordinate (x,y,z) and time (t) variables available in the function expression."}>>> = true

expression<<<{"description": "Parsed function expression to compute"}>>> = 'z'

[]

[]For visualization purposes, we use a CellTemperatureAux to view the temperature set in each OpenMC cell and a CellDensityAux to view the density set in each fluid OpenMC cell. To understand how the OpenMC model maps to the [Mesh], we also include CellMaterialIDAux. Cardinal will also automatically output a variable named cell_id (CellIDAux) and a variable named cell_instance ( CellInstanceAux) to show the spatial mapping. Next, we add a receiver flux variable that will hold the heat flux received from MOOSE (and sent to THM) and another receiver variable thm_temp_wall that will hold the wall temperature received from THM (and sent to MOOSE).

Finally, to reduce the number of transfers from THM, we will receive fluid temperature from THM, but re-compute the density locally in the OpenMC wrapping using a FluidDensityAux with the same EOS as used in the THM input files.

[FluidProperties<<<{"href": "../syntax/FluidProperties/index.html"}>>>]

[helium]

type = IdealGasFluidProperties<<<{"description": "Fluid properties for an ideal gas", "href": "../source/fluidproperties/IdealGasFluidProperties.html"}>>>

molar_mass<<<{"description": "Constant molar mass of the fluid (kg/mol)"}>>> = 4e-3

gamma<<<{"description": "gamma value (cp/cv)"}>>> = 1.668282 # should correspond to Cp = 5189 J/kg/K

k<<<{"description": "Thermal conductivity, W/(m-K)"}>>> = 0.2556

mu<<<{"description": "Dynamic viscosity, Pa.s"}>>> = 3.22639e-5

[]

[]Next, we set initial conditions for the fluid wall temperature, the fluid bulk temperature, and the heat source. We set these initial conditions in the OpenMC wrapper because the very first time that the transfers to the MOOSE heat conduction module and to THM occur, these initial conditions will be passed.

[ICs<<<{"href": "../syntax/Cardinal/ICs/index.html"}>>>]

[fluid_temp_wall]

type = FunctionIC<<<{"description": "An initial condition that uses a normal function of x, y, z to produce values (and optionally gradients) for a field variable.", "href": "../source/ics/FunctionIC.html"}>>>

variable<<<{"description": "The variable this initial condition is supposed to provide values for."}>>> = thm_temp_wall

function<<<{"description": "The initial condition function."}>>> = temp_ic

[]

[fluid_temp]

type = FunctionIC<<<{"description": "An initial condition that uses a normal function of x, y, z to produce values (and optionally gradients) for a field variable.", "href": "../source/ics/FunctionIC.html"}>>>

variable<<<{"description": "The variable this initial condition is supposed to provide values for."}>>> = thm_temp

function<<<{"description": "The initial condition function."}>>> = temp_ic

[]

[heat_source]

type = ConstantIC<<<{"description": "Sets a constant field value.", "href": "../source/ics/ConstantIC.html"}>>>

variable<<<{"description": "The variable this initial condition is supposed to provide values for."}>>> = heat_source

block<<<{"description": "The list of blocks (ids or names) that this object will be applied"}>>> = 'compacts'

value<<<{"description": "The value to be set in IC"}>>> = ${fparse power / (n_bundles * n_fuel_compacts_per_block) / (pi * compact_diameter * compact_diameter / 4.0 * height)}

[]

[]

[Functions<<<{"href": "../syntax/Functions/index.html"}>>>]

[temp_ic]

type = ParsedFunction<<<{"description": "Function created by parsing a string", "href": "../source/functions/MooseParsedFunction.html"}>>>

expression<<<{"description": "The user defined function."}>>> = '${inlet_T} + (${height} - z) / ${height} * ${power} / ${mdot} / ${fluid_Cp}'

[]

[]The [Problem] and [Tallies] blocks are then used to specify settings for the OpenMC wrapping. We define the total power for normalization, indicate that blocks 1, 2, and 4 are solid (graphite, compacts, and poison) while block 101 is fluid. We add a CellTally to block 2, the fuel compacts. Because OpenMC solves in units of centimeters, we specify a scaling of 100, i.e. a multiplicative factor to apply to the [Mesh] to get into OpenMC's centimeter units.

[Problem<<<{"href": "../syntax/Problem/index.html"}>>>]

type = OpenMCCellAverageProblem

identical_cell_fills = '2'

power = '${fparse power / n_bundles}'

scaling = 100.0

cell_level = 1

relaxation = constant

relaxation_factor = 0.5

# to get a faster-running tutorial, we use only 1000 particles per batch; converged

# results are instead obtained by increasing this parameter to 10000. We also use fewer

# batches to speed things up; the converged results were obtained with 500 inactive batches

# and 2000 active batches

particles = 1000

inactive_batches = 200

batches = 1000

# we will read temperature from THM (for the fluid) and MOOSE (for the solid)

# into variables we name as 'solid_temp' and 'thm_temp'. This syntax will automatically

# create those variabes for us

temperature_variables = 'solid_temp; thm_temp'

temperature_blocks = '1 2 4; 101'

density_blocks = '101'

[Tallies<<<{"href": "../syntax/Problem/Tallies/index.html"}>>>]

[heat_source]

type = CellTally<<<{"description": "A class which implements distributed cell tallies.", "href": "../source/tallies/CellTally.html"}>>>

block<<<{"description": "Subdomains for which to add tallies in OpenMC. If not provided, cell tallies will be applied over the entire mesh."}>>> = '2'

name<<<{"description": "Auxiliary variable name(s) to use for OpenMC tallies. If not specified, defaults to the names of the scores"}>>> = heat_source

check_equal_mapped_tally_volumes<<<{"description": "Whether to check if the tallied cells map to regions in the mesh of equal volume. This can be helpful to ensure that the volume normalization of OpenMC's tallies doesn't introduce any unintentional distortion just because the mapped volumes are different. You should only set this to true if your OpenMC tally cells are all the same volume!"}>>> = true

output<<<{"description": "UNRELAXED field(s) to output from OpenMC for each tally score. unrelaxed_tally_std_dev will write the standard deviation of each tally into auxiliary variables named *_std_dev. unrelaxed_tally_rel_error will write the relative standard deviation (unrelaxed_tally_std_dev / unrelaxed_tally) of each tally into auxiliary variables named *_rel_error. unrelaxed_tally will write the raw unrelaxed tally into auxiliary variables named *_raw (replace * with 'name')."}>>> = 'unrelaxed_tally_std_dev'

[]

[]

[]Other features we use include an output of the fission tally standard deviation in units of W/m to the [Mesh] by setting output = 'unrelaxed_tally_std_dev'. This is used to obtain uncertainty estimates of the heat source distribution from OpenMC in the same units as the heat source. We also leverage a helper utility in CellTally by setting check_equal_mapped_tally_volumes = true. This parameter will throw an error if the tallied OpenMC cells map to different volumes in the MOOSE domain. Because we know a priori that the equal-volume OpenMC tally cells should all map to equal volumes, this will help ensure that the volumes used for heat source normalization are also all equal. For further discussion of this setting and a pictorial description of the possible effect of non-equal mapped vlumes, please see the OpenMCCellAverageProblem documentation.

We also set identical_cell_fills to the set of subdomains for which OpenMC's cells have identical fills. This is an optimization that greatly reduces the initialization time for large TRISO problems. During setup of an OpenMC wrapping, we need to cache all the cells contained within the TRISO compacts so that we know all the contained cells to set the temperatures for. This process can be quite time-consuming if the search needs to be repeated for every single TRISO compact cell (210 compacts times 50 axial layers = 10,500 contained cell searches). The identical_cell_fills option is used to indicate whether your problem can leverage a speedup that applies to models where every lattice/universe-filled tally cell has exactly the same filling lattice/universe. In other words, we set up our problem to use the same TRISO universe in each layer of each fuel compact. This means that the cells filling each TRISO compact can be deduced by following a pattern based on the first two fuel compacts, letting us omit 10,498 of the contained cell searches.

When first using this optimization for a new problem, we recommend setting check_identical_cell_fills = true so that you can do an exact comparison against the "rigorous" approach to be sure that your problem setup has the necessary prerequisites to use this feature. After you verify that no errors are thrown during setup, set check_identical_cell_fills to false (the default) to use this initialization speedup feature.

Because the blocks in the OpenMC mesh mirror receive temperatures from different applications, we use the temperature_variables and temperature_blocks parameters of OpenMCCellAverageProblem to automatically create separate variables for OpenMC to read temperature from in different parts of the domain. The temperature_blocks and temperature_variables parameters allow you to customize exactly the variable names from which to read temperature.

Finally, we apply a constant relaxation model to the heat source. A constant relaxation will compute the heat source in iteration as an average of the heat source from iteration and the most-recently-computed heat source, indicated here as a generic operator which represents the Monte Carlo solve:

(5)

In Eq. (5), is the relaxation factor, which we set here to 0.5. In other words, the heat source in iteration is an average of the most recent Monte Carlo solution and the previous iterate. This is necessary to accelerate the fixed point iterations and achieve convergence in a reasonable time - otherwise oscillations can occur in the coupled physics.

We run OpenMC as the main application, so we next need to define MultiApps to run the solid heat conduction model and the THM fluid model as the sub-applications. We also require a number of transfers both for 1) sending necessary coupling data between the three applications and 2) visualizing the combined THM output. To couple OpenMC to MOOSE heat conduction, we use four transfers:

MultiAppShapeEvaluationTransfer to transfer:

power from OpenMC to MOOSE (with conservation of total power)

MultiAppGeometricInterpolationTransfer to transfer:

solid temperature from MOOSE to OpenMC

wall temperature from OpenMC (which doesn't directly compute the wall temperature, but instead receives it from THM through a separate transfer) to MOOSE

MultiAppGeneralFieldNearestLocationTransfer to transfer and conserve heat flux from MOOSE to OpenMC (which isn't used directly in OpenMC, but instead gets sent later to THM through a separate transfer)

To couple OpenMC to THM, we require three transfers:

MultiAppGeneralFieldUserObjectTransfer to send the layer-averaged wall heat flux from OpenMC (which computes the layered-average heat flux from the heat flux received from MOOSE heat conduction) to THM

MultiAppGeneralFieldNearestLocationTransfer to transfer:

fluid wall temperature from THM to OpenMC (which isn't used directly in OpenMC, but instead gets sent to MOOSE heat conduction in a separate transfer)

fluid bulk temperature from THM to OpenMC

For visualization purposes, we also send the pressure and velocity computed by THM to the OpenMC mesh mirror.

[MultiApps<<<{"href": "../syntax/MultiApps/index.html"}>>>]

[bison]

type = TransientMultiApp<<<{"description": "MultiApp for performing coupled simulations with the parent and sub-application both progressing in time.", "href": "../source/multiapps/TransientMultiApp.html"}>>>

input_files<<<{"description": "The input file for each App. If this parameter only contains one input file it will be used for all of the Apps. When using 'positions_from_file' it is also admissable to provide one input_file per file."}>>> = 'solid.i'

execute_on<<<{"description": "The list of flag(s) indicating when this object should be executed. For a description of each flag, see https://mooseframework.inl.gov/source/interfaces/SetupInterface.html."}>>> = timestep_begin

[]

[thm]

type = FullSolveMultiApp<<<{"description": "Performs a complete simulation during each execution.", "href": "../source/multiapps/FullSolveMultiApp.html"}>>>

input_files<<<{"description": "The input file for each App. If this parameter only contains one input file it will be used for all of the Apps. When using 'positions_from_file' it is also admissable to provide one input_file per file."}>>> = 'thm.i'

execute_on<<<{"description": "The list of flag(s) indicating when this object should be executed. For a description of each flag, see https://mooseframework.inl.gov/source/interfaces/SetupInterface.html."}>>> = timestep_end

max_procs_per_app<<<{"description": "Maximum number of processors to give to each App in this MultiApp. Useful for restricting small solves to just a few procs so they don't get spread out"}>>> = 1

bounding_box_padding<<<{"description": "Additional padding added to the dimensions of the bounding box. The values are added to the x, y and z dimension respectively."}>>> = '0.1 0.1 0'

positions_file<<<{"description": "Filename(s) that should be looked in for positions. Each set of 3 values in that file will represent a Point. This and 'positions(_objects)' cannot be both supplied"}>>> = coolant_channel_positions.txt

output_in_position<<<{"description": "If true this will cause the output from the MultiApp to be 'moved' by its position vector"}>>> = true

[]

[]

[Transfers<<<{"href": "../syntax/Transfers/index.html"}>>>]

[solid_temp_to_openmc]