TRISO Compacts

In this tutorial, you will learn how to:

Couple OpenMC via temperature and heat source feedback to MOOSE for Tri-Structural Isotropic (TRISO) fuels

Establish coupling between OpenMC and MOOSE for nested universe OpenMC models

Apply homogenized temperature feedback to heterogeneous OpenMC cells

To access this tutorial,

cd cardinal/tutorials/gas_compactCardinal contains convenient features for applying multiphysics feedback to heterogeneous domains, when a coupled physics application (such as the MOOSE heat transfer module) might not also resolve the heterogeneities. For instance, the fuel pebble model in Pronghorn Novak et al. (2021) uses the Heat Source Decomposition method to predict pebble interior temperatures, which does not explicitly resolve the TRISO particles in the pebble. However, it is usually important to explicitly resolve the particles for Monte Carlo simulations, to correctly capture self-shielding. Cardinal allows temperatures to be applied to OpenMC cells that contain nested universes or lattices by recursing through all the cells filling the given cell and setting the temperature of all contained cells. This tutorial describes how to use this feature for coupling of OpenMC to MOOSE for a TRISO fuel compact. This example only considers coupling of OpenMC via temperature feedback - in a later tutorial, we extend this example to consider density feedback as well.

This tutorial was developed with support from the NEAMS Thermal Fluids Center of Excellence. A journal article Novak et al. (2022) describing the physics models, mesh refinement studies, and auxiliary analyses provides additional context and application examples beyond the scope of this tutorial.

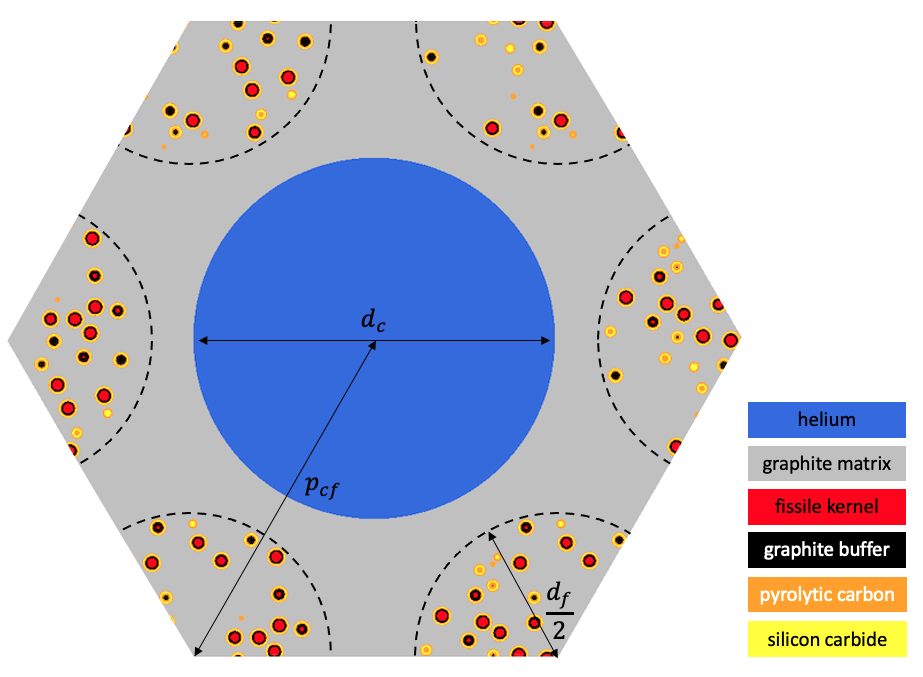

Geometry and Computational Model

The geometry consists of a unit cell of a TRISO-fueled gas reactor compact INL (2016). A top-down view of the geometry is shown in Figure 1. The fuel is cooled by helium flowing in a cylindrical channel of diameter dc. Cylindrical fuel compacts containing randomly-dispersed TRISO particles at 15% packing fraction are arranged around the coolant channel in a triangular lattice; the distance between the compact and coolant channel centers is pcf. The diameter of the fuel compact cylinders is df. The TRISO particles use a conventional design that consists of a central fissile uranium oxycarbide kernel enclosed in a carbon buffer, an inner Pyrolitic Carbon (PyC) layer, a silicon carbide layer, and finally an outer PyC layer. The geometric specifications are summarized in Table 1. Heat is produced in the TRISO particles to yield a total power of 30 kW.

Figure 1: TRISO-fueled gas reactor compact unit cell

Table 1: Geometric specifications for a TRISO-fueled gas reactor compact

| Parameter | Value (cm) |

|---|---|

| Coolant channel diameter | 1.6 |

| Fuel compact diameter | 1.27 |

| Fuel-to-coolant center distance | 1.628 |

| Height | 160 |

| TRISO kernel radius | 214.85e-4 |

| Buffer layer radius | 314.85e-4 |

| Inner PyC layer radius | 354.85e-4 |

| Silicon carbide layer radius | 389.85e-4 |

| Outer PyC layer radius | 429.85e-4 |

Heat Conduction Model

The MOOSE heat transfer module is used to solve for steady-state heat conduction,

−∇⋅(ks∇Ts)=q˙s(1)

where ks is the solid thermal conductivity, Ts is the solid temperature, and q˙s is a volumetric heat source in the solid.

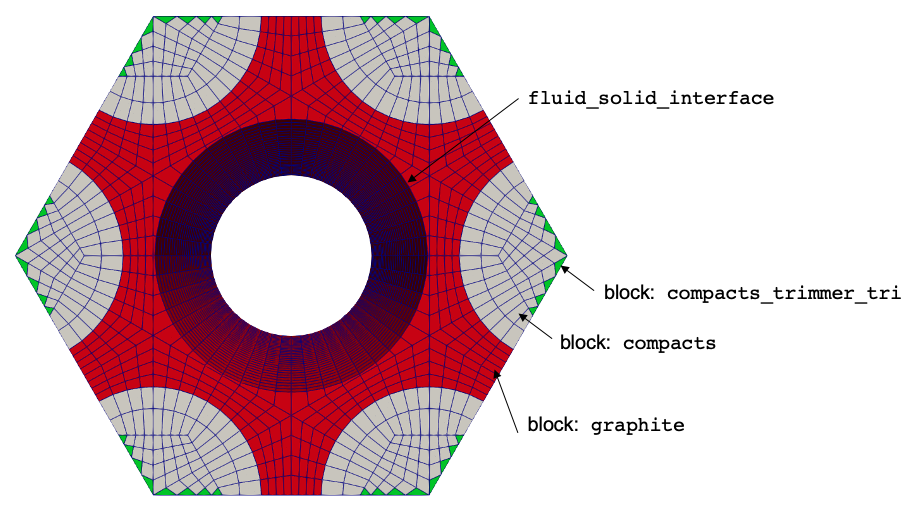

The solid mesh is shown in Figure 2; the only sideset defined in the domain is the coolant channel surface. The solid geometry uses a length unit of meters.

Figure 2: Mesh for the solid heat conduction model

This mesh is generated using MOOSE mesh generators in the mesh.i file.

[Mesh]

[fuel_pin]

type = PolygonConcentricCircleMeshGenerator

num_sides = 6

polygon_size = '${fparse fuel_to_coolant_distance / 2.0}'

ring_radii = '${fparse 0.8 * compact_diameter / 2.0} ${fparse compact_diameter / 2.0}'

ring_intervals = '1 1'

num_sectors_per_side = '${ns} ${ns} ${ns} ${ns} ${ns} ${ns}'

ring_block_ids = '2 2'

ring_block_names = 'compacts compacts'

background_block_names = 'graphite'

background_intervals = 4

[]

[coolant_pin]

type = PolygonConcentricCircleMeshGenerator

num_sides = 6

polygon_size = '${fparse fuel_to_coolant_distance / 2.0}'

ring_radii = '${fparse channel_diameter / 2.0}'

ring_intervals = '2'

num_sectors_per_side = '${ns} ${ns} ${ns} ${ns} ${ns} ${ns}'

ring_block_ids = '101 101'

ring_block_names = 'coolant coolant'

background_block_names = 'graphite'

interface_boundary_id_shift = 100

background_intervals = 1

[]

[bundle]

type = PatternedHexMeshGenerator

inputs = 'fuel_pin coolant_pin'

hexagon_size = '${fparse 2.0 * fuel_to_coolant_distance}'

pattern = '0 0;

0 1 0;

0 0'

[]

[trim]

type = HexagonMeshTrimmer

input = bundle

trim_peripheral_region = '1 1 1 1 1 1'

peripheral_trimming_section_boundary = peripheral_section

[]

[rotate]

type = TransformGenerator

input = trim

transform = rotate

vector_value = '30.0 0.0 0.0'

[]

[extrude]

type = AdvancedExtruderGenerator

input = rotate

heights = ${height}

num_layers = ${n_layers}

direction = '0 0 1'

[]

[fluid_solid_interface]

type = SideSetsBetweenSubdomainsGenerator

input = extrude

primary_block = 'graphite'

paired_block = 'coolant'

new_boundary = 'fluid_solid_interface'

[]

[delete_coolant]

type = BlockDeletionGenerator

input = fluid_solid_interface

block = 'coolant'

[]

[]We first create a full 7-pin bundle, and then apply a trimming operation to split the compacts. Because MOOSE does not support multiple element types (e.g. tets, hexes) on the same block ID, the trimmer automatically creates an additional block (compacts_trimmer_tri) to represent the triangular prism elements formed in the compacts. You can generate this mesh by running

cardinal-opt -i mesh.i --mesh-onlywhich will create the mesh, named mesh_in.e.

Because this tutorial only considers temperature coupling, no fluid flow and heat transfer in the helium is modeled. Therefore, heat removal by the fluid is approximated by setting the coolant channel surface to a Dirichlet temperature condition of Ts=Tf, where Tf is given as

2π4dc2∫0zq(l)dl=m˙Cp,f(Tf(z)−Tinlet)(2)

where q is the fission volumetric power density, m˙ is the mass flowrate, Cp,f is the fluid isobaric specific heat capacity, Tf is the fluid temperature, and Tinlet is the fluid inlet temperature. Although we will be computing power with OpenMC, just for the sake of applying a fluid temperature boundary condition, we assume the axial power distribution is sinusoidal,

q(z)=q0sin(Hπz)(3)

where H is the compact height and q0 is a constant to obtain the total specified power of 30 kW. The nominal fluid mass flowrate is 0.011 kg/s and the inlet temperature is 325°C. All other boundaries in the solid domain are insulated. We will run the OpenMC model first, so the only initial condition required for the solid model is an initial temperature of 325°C.

OpenMC Model

The OpenMC model is built using Constructive Solid Geometry (CSG). The TRISO positions are sampled using the Random Sequential Addition (RSA) algorithm in OpenMC. OpenMC's Python API is used to create the model with the script shown below. First, we define materials for the various regions. Next, we create a single TRISO particle universe consisting of the five layers of the particle and an infinite extent of graphite filling all other space. We then pack pack uniform-radius spheres into a cylindrical region representing a fuel compact, setting each sphere to be filled with the TRISO universe.

#!/bin/env python

from argparse import ArgumentParser

import math

import numpy as np

import matplotlib.pyplot as plt

import openmc

outlet_P = 7.1e6 # fluid outlet pressure (Pa)

inlet_T = 598.0 # inlet fluid temperature (K)

power = 30e3 # unit cell power (W)

mdot = 0.011 # fluid mass flowrate (kg/s)

fluid_Cp = 5189.0 # fluid isobaric specific heat (J/kg/K)

channel_diameter = 0.016 # diameter of the coolant channels (m)

compact_diameter = 0.0127 # diameter of fuel compacts (m)

fuel_to_coolant_distance = 0.01628 # distance between center of fuel compact and coolant channel (m)

height = 1.60 # height of the unit cell (m)

triso_pf = 0.15 # TRISO packing fraction (%)

kernel_radius = 214.85e-6 # fissile kernel outer radius (m)

buffer_radius = 314.85e-6 # buffer outer radius (m)

iPyC_radius = 354.85e-6 # inner PyC outer radius (m)

SiC_radius = 389.85e-6 # SiC outer radius (m)

oPyC_radius = 429.85e-6 # outer PyC outer radius (m)

enrichment = 0.155 # fuel enrichment (weight percent)

kernel_density = 10820 # fissile kernel density (kg/m3)

buffer_density = 1050 # buffer density (kg/m3)

PyC_density = 1900 # PyC density (kg/m3)

SiC_density = 3203 # SiC density (kg/m3)

matrix_density = 1700 # graphite matrix density (kg/m3)

def coolant_temp(t_in, t_out, l, z):

"""

THIS IS ONLY USED FOR SETTING AN INITIAL CONDITION IN OPENMC's XML FILES -

the coolant temperature will be applied from MOOSE, we just set an initial

value here in case you want to run these files in standalone mode (i.e. with

the "openmc" executable).

Computes the coolant temperature based on an expected cosine power distribution

for a specified temperature rise. The total core temperature rise is governed

by energy conservation as dT = Q / m / Cp, where dT is the total core temperature

rise, Q is the total core power, m is the mass flowrate, and Cp is the fluid

isobaric specific heat. If you neglect axial heat conduction and assume steady

state, then the temperature rise in a layer of fluid i can be related to the

ratio of the power in that layer to the total power,

dT_i / dT = Q_i / Q. We assume here a sinusoidal power distribution to get

a reasonable estimate of an initial coolant temperature distribution.

Parameters

----------

t_in : float

Inlet temperature of the channel

t_out : float

Outlet temperature of the channel

l : float

Length of the channel

z : float or 1-D numpy.array

Axial position where the temperature will be computed

Returns

-------

float or 1-D numpy array of float depending on z

"""

dT = t_out - t_in

Q = 2 * l / math.pi

Qi = (l - l * np.cos(math.pi * z / l)) / math.pi

t = t_in + Qi / Q * dT

return t

def coolant_density(t):

"""

THIS IS ONLY USED FOR SETTING AN INITIAL CONDITION IN OPENMC's XML FILES -

the coolant density will be applied from MOOSE, we just set an initial

value here in case you want to run these files in standalone mode (i.e. with

the "openmc" executable).

Computes the helium density (kg/m3) from temperature assuming a fixed operating pressure.

Parameters

----------

t : float

Fluid temperature

Returns

_______

float or 1-D numpy array of float depending on t

"""

p_in_bar = outlet_P * 1.0e-5

return 48.14 * p_in_bar / (t + 0.4446 * p_in_bar / math.pow(t, 0.2))

# -------------- Unit Conversions: OpenMC requires cm -----------

m = 100.0

# -------------------------------------------

### RADIANT UNIT CELL SPECS (INFERRED FROM REPORTS) ###

# estimate the outlet temperature using bulk energy conservation for steady state

coolant_outlet_temp = power / mdot / fluid_Cp + inlet_T

# geometry

coolant_channel_diam = channel_diameter * m

reactor_bottom = 0.0

reactor_height = height * m

reactor_top = reactor_bottom + reactor_height

### ARBITRARILY DETERMINED PARAMETERS ###

cell_pitch = fuel_to_coolant_distance * m

fuel_channel_diam = compact_diameter * m

hex_orientation = 'x'

def unit_cell(n_ax_zones, n_inactive, n_active, add_entropy_mesh=False):

axial_section_height = reactor_height / n_ax_zones

# superimposed search lattice

triso_lattice_shape = (4, 4, int(axial_section_height / 0.125))

lattice_orientation = 'x'

cell_edge_length = cell_pitch

model = openmc.model.Model()

### Materials ###

enrichment_234 = 2e-3

# TRISO Materials

m_fuel = openmc.Material(name='fuel')

enrichment_uranium = enrichment

mass_234 = openmc.data.atomic_mass('U234')

mass_235 = openmc.data.atomic_mass('U235')

mass_238 = openmc.data.atomic_mass('U238')

# number of atoms in one gram of uranium mixture

n_234 = enrichment_234 / mass_234

n_235 = enrichment_uranium / mass_235

n_238 = (1.0 - enrichment_uranium - enrichment_234) / mass_238

total_n = n_234 + n_235 + n_238

m_fuel.add_nuclide('U234', n_234 / total_n)

m_fuel.add_nuclide('U235', n_235 / total_n)

m_fuel.add_nuclide('U238', n_238 / total_n)

m_fuel.add_element('C' , 1.50)

m_fuel.add_element('O' , 0.50)

m_fuel.set_density('kg/m3', kernel_density)

#

m_graphite_c_buffer = openmc.Material(name='buffer')

m_graphite_c_buffer.add_element('C', 1.0)

m_graphite_c_buffer.add_s_alpha_beta('c_Graphite')

m_graphite_c_buffer.set_density('kg/m3', buffer_density)

#

m_graphite_pyc = openmc.Material(name='pyc')

m_graphite_pyc.add_element('C', 1.0)

m_graphite_pyc.add_s_alpha_beta('c_Graphite')

m_graphite_pyc.set_density('kg/m3', PyC_density)

#

m_sic = openmc.Material(name='sic')

m_sic.add_element('C' , 1.0)

m_sic.add_element('Si', 1.0)

m_sic.set_density('kg/m3', SiC_density)

# Graphite moderator

m_graphite_matrix = openmc.Material(name='graphite moderator')

m_graphite_matrix.add_element('C', 1.0)

m_graphite_matrix.add_s_alpha_beta('c_Graphite')

m_graphite_matrix.set_density('kg/m3', matrix_density)

# Coolant

m_coolant = openmc.Material(name='Helium coolant')

m_coolant.add_element('He', 1.0, 'ao')

### Geometry ###

# TRISO particle

radius_pyc_outer = oPyC_radius * m

s_fuel = openmc.Sphere(r=kernel_radius*m)

s_c_buffer = openmc.Sphere(r=buffer_radius*m)

s_pyc_inner = openmc.Sphere(r=iPyC_radius*m)

s_sic = openmc.Sphere(r=SiC_radius*m)

s_pyc_outer = openmc.Sphere(r=radius_pyc_outer)

c_triso_fuel = openmc.Cell(name='c_triso_fuel' , fill=m_fuel, region=-s_fuel)

c_triso_c_buffer = openmc.Cell(name='c_triso_c_buffer' , fill=m_graphite_c_buffer, region=+s_fuel & -s_c_buffer)

c_triso_pyc_inner = openmc.Cell(name='c_triso_pyc_inner', fill=m_graphite_pyc, region=+s_c_buffer & -s_pyc_inner)

c_triso_sic = openmc.Cell(name='c_triso_sic' , fill=m_sic, region=+s_pyc_inner & -s_sic)

c_triso_pyc_outer = openmc.Cell(name='c_triso_pyc_outer', fill=m_graphite_pyc, region=+s_sic & -s_pyc_outer)

c_triso_matrix = openmc.Cell(name='c_triso_matrix' , fill=m_graphite_matrix, region=+s_pyc_outer)

u_triso = openmc.Universe(cells=[c_triso_fuel, c_triso_c_buffer, c_triso_pyc_inner, c_triso_sic, c_triso_pyc_outer, c_triso_matrix])

# Channel surfaces

fuel_cyl = openmc.ZCylinder(r=0.5 * fuel_channel_diam)

coolant_cyl = openmc.ZCylinder(r=0.5 * coolant_channel_diam)

# create a TRISO lattice for one axial section (to be used in the rest of the axial zones)

# center the TRISO region on the origin so it fills lattice cells appropriately

min_z = openmc.ZPlane(z0=-0.5 * axial_section_height)

max_z = openmc.ZPlane(z0=0.5 * axial_section_height)

# region in which TRISOs are generated

r_triso = -fuel_cyl & +min_z & -max_z

rand_spheres = openmc.model.pack_spheres(radius=radius_pyc_outer, region=r_triso, pf=triso_pf, seed=1.0)

random_trisos = [openmc.model.TRISO(radius_pyc_outer, u_triso, i) for i in rand_spheres]

llc, urc = r_triso.bounding_box

pitch = (urc - llc) / triso_lattice_shape

# insert TRISOs into a lattice to accelerate point location queries

triso_lattice = openmc.model.create_triso_lattice(random_trisos, llc, pitch, triso_lattice_shape, m_graphite_matrix)

# create a hexagonal lattice for the coolant and fuel channels

fuel_univ = openmc.Universe(cells=[openmc.Cell(region=-fuel_cyl, fill=triso_lattice),

openmc.Cell(region=+fuel_cyl, fill=m_graphite_matrix)])

# extract the coolant cell and set temperatures based on the axial profile

coolant_cell = openmc.Cell(region=-coolant_cyl, fill=m_coolant)

# set the coolant temperature on the cell to approximately match the expected

# temperature profile

axial_coords = np.linspace(reactor_bottom, reactor_top, n_ax_zones + 1)

lattice_univs = []

fuel_ch_cells = []

i = 0

for z_min, z_max in zip(axial_coords[0:-1], axial_coords[1:]):

# create a new coolant universe for each axial zone in the coolant channel;

# this generates a new material as well (we only need to do this for all

# cells except the first cell)

if (i == 0):

c_cell = coolant_cell

else:

c_cell = coolant_cell.clone()

i += 1

# use the middle of the axial section to compute the temperature and density

ax_pos = 0.5 * (z_min + z_max)

t = coolant_temp(inlet_T, coolant_outlet_temp, reactor_height, ax_pos)

c_cell.temperature = t

coolant_cell.fill.set_density('kg/m3', coolant_density(t))

# set the solid cells and their temperatures

graphite_cell = openmc.Cell(region=+coolant_cyl, fill=m_graphite_matrix)

fuel_ch_cell = openmc.Cell(region=-fuel_cyl, fill=triso_lattice)

fuel_ch_matrix_cell = openmc.Cell(region=+fuel_cyl, fill=m_graphite_matrix)

graphite_cell.temperature = t

fuel_ch_cell.temperature = t

fuel_ch_matrix_cell.temperature = t

fuel_ch_cells.append(fuel_ch_cell)

fuel_u = openmc.Universe(cells=[fuel_ch_cell, fuel_ch_matrix_cell])

coolant_u = openmc.Universe(cells=[c_cell, graphite_cell])

lattice_univs.append([[fuel_u] * 6, [coolant_u]])

# create a hexagonal lattice used in each axial zone to represent the cell

hex_lattice = openmc.HexLattice(name="Unit cell lattice")

hex_lattice.orientation = lattice_orientation

hex_lattice.center = (0.0, 0.0, 0.5 * (reactor_bottom + reactor_top))

hex_lattice.pitch = (cell_pitch, axial_section_height)

hex_lattice.universes = lattice_univs

graphite_outer_cell = openmc.Cell(fill=m_graphite_matrix)

graphite_outer_cell.temperature = t

inf_graphite_univ = openmc.Universe(cells=[graphite_outer_cell])

hex_lattice.outer = inf_graphite_univ

# hexagonal bounding cell

hex = openmc.model.HexagonalPrism(cell_edge_length, hex_orientation, boundary_type='periodic')

hex_cell_vol = 6.0 * (math.sqrt(3) / 4.0) * cell_edge_length**2 * reactor_height

# create additional axial regions

axial_planes = [openmc.ZPlane(z0=coord) for coord in axial_coords]

# axial planes

min_z = axial_planes[0]

min_z.boundary_type = 'vacuum'

max_z = axial_planes[-1]

max_z.boundary_type = 'vacuum'

# fill the unit cell with the hex lattice

hex_cell = openmc.Cell(region=-hex & +min_z & -max_z, fill=hex_lattice)

model.geometry = openmc.Geometry([hex_cell])

### Settings ###

settings = openmc.Settings()

settings.particles = 10000

settings.inactive = n_inactive

settings.batches = settings.inactive + n_active

# the only reason we use 'nearest' here is to be sure we have a robust test for CI;

# otherwise, 1e-16 differences in temperature (due to numerical roundoff when using

# different MPI ranks) do change the tracking do to the stochastic interpolation

settings.temperature['method'] = 'nearest'

settings.temperature['range'] = (294.0, 1500.0)

settings.temperature['tolerance'] = 200.0

hexagon_half_flat = math.sqrt(3.0) / 2.0 * cell_edge_length

lower_left = (-cell_edge_length, -hexagon_half_flat, reactor_bottom)

upper_right = (cell_edge_length, hexagon_half_flat, reactor_top)

source_dist = openmc.stats.Box(lower_left, upper_right)

source = openmc.IndependentSource(space=source_dist)

settings.source = source

if (add_entropy_mesh):

entropy_mesh = openmc.RegularMesh()

entropy_mesh.lower_left = lower_left

entropy_mesh.upper_right = upper_right

entropy_mesh.dimension = (5, 5, 20)

settings.entropy_mesh = entropy_mesh

model.settings = settings

m_colors = {m_coolant: 'royalblue', m_fuel: 'red', m_graphite_c_buffer: 'black', m_graphite_pyc: 'orange', m_sic: 'yellow', m_graphite_matrix: 'silver'}

plot1 = openmc.Plot()

plot1.filename = 'plot1'

plot1.width = (2 * cell_pitch, 4 * axial_section_height)

plot1.basis = 'xz'

plot1.origin = (0.0, 0.0, reactor_height/2.0)

plot1.pixels = (int(800 * 2 * cell_pitch), int(800 * 4 * axial_section_height))

plot1.color_by = 'cell'

plot2 = openmc.Plot()

plot2.filename = 'plot2'

plot2.width = (3 * cell_pitch, 3 * cell_pitch)

plot2.basis = 'xy'

plot2.origin = (0.0, 0.0, axial_section_height / 2.0)

plot2.pixels = (int(800 * cell_pitch), int(800 * cell_pitch))

plot2.color_by = 'material'

plot2.colors = m_colors

plot3 = openmc.Plot()

plot3.filename = 'plot3'

plot3.width = plot2.width

plot3.basis = plot2.basis

plot3.origin = plot2.origin

plot3.pixels = plot2.pixels

plot3.color_by = 'cell'

model.plots = openmc.Plots([plot1, plot2, plot3])

return model

def main():

ap = ArgumentParser()

ap.add_argument('-n', dest='n_axial', type=int, default=30,

help='Number of axial cell divisions (defaults to value in common_input.i)')

ap.add_argument('-s', '--entropy', action='store_true',

help='Whether to add a Shannon entropy mesh')

ap.add_argument('-i', dest='n_inactive', type=int, default=25,

help='Number of inactive cycles')

ap.add_argument('-a', dest='n_active', type=int, default=200,

help='Number of active cycles')

args = ap.parse_args()

model = unit_cell(args.n_axial, args.n_inactive, args.n_active, args.entropy)

model.export_to_xml()

if __name__ == "__main__":

main()Finally, we loop over nl axial layers and create unique cells for each of the six compacts, the graphite block, and the coolant. The level on which we will apply feedback from MOOSE is set to 1 because each layer is a component in a lattice nested once with respect to the highest level. To accelerate the particle tracking, we:

Repeat the same TRISO universe in each axial layer and within each compact

Superimpose a Cartesian search lattice in the fuel channel regions.

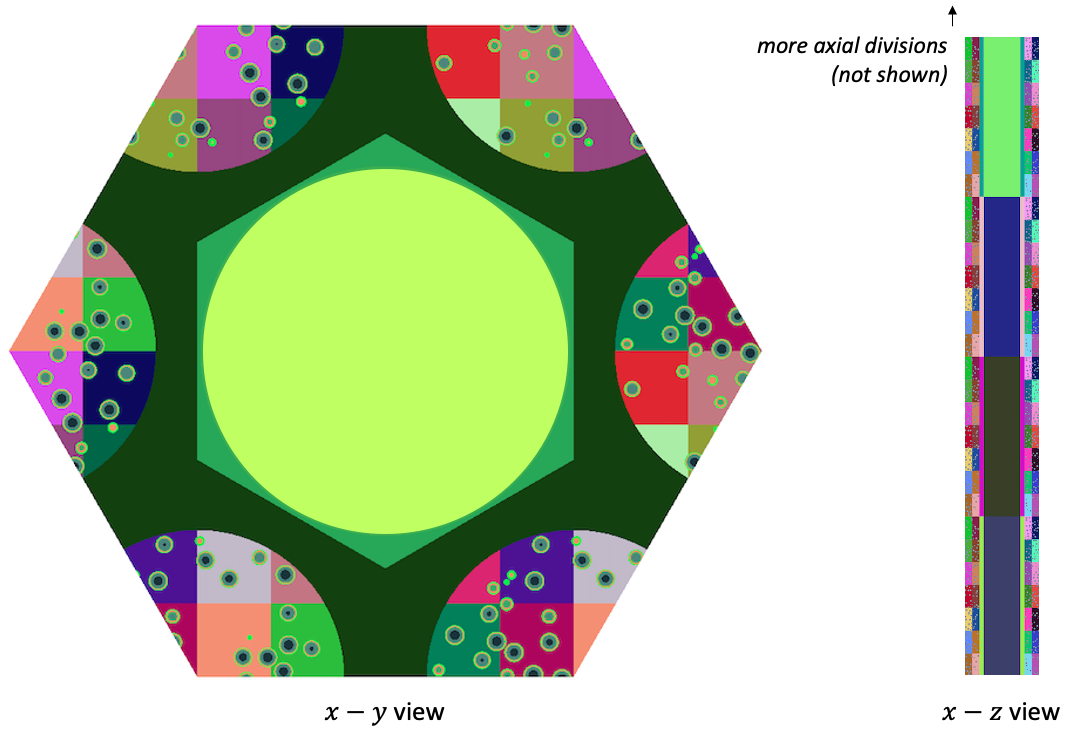

The OpenMC geometry, colored by cell ID, is shown in Figure 3. The lateral faces of the unit cell are periodic, while the top and bottom boundaries are vacuum. The Cartesian search lattice in the fuel compact regions is also visible.

Figure 3: OpenMC model, colored by cell ID

Because we will run OpenMC first, the initial temperature is set to a uniform distribution in the x-y plane with the axial distribution given by Eq. (2). The fluid density is set using a helium correlation at a fixed pressure of 7.1 MPa Petersen (1970) given the imposed temperature, i.e. ρf(P,T).

To create the XML files required to run OpenMC, run the script:

python unit_cell.pyYou can also use the XML files checked in to the tutorials/gas_compact directory.

Multiphysics Coupling

In this section, OpenMC and MOOSE are coupled for heat source and temperature feedback for the solid regions of a TRISO-fueled gas reactor compact. The following sub-sections describe these files.

Solid Input Files

The solid phase is solved with the MOOSE heat transfer module, and is described in the solid.i input. We define a number of constants at the beginning of the file and set up the mesh from a file.

compact_diameter = 0.0127 # diameter of fuel compacts (m)

height = 1.60 # height of the unit cell (m)

triso_pf = 0.15 # TRISO packing fraction (%)

kernel_radius = 214.85e-6 # fissile kernel outer radius (m)

buffer_radius = 314.85e-6 # buffer outer radius (m)

iPyC_radius = 354.85e-6 # inner PyC outer radius (m)

SiC_radius = 389.85e-6 # SiC outer radius (m)

oPyC_radius = 429.85e-6 # outer PyC outer radius (m)

# material parameters

fluid_Cp = 5189.0 # fluid isobaric specific heat (J/kg/K)

buffer_k = 0.5 # buffer thermal conductivity (W/m/K)

PyC_k = 4.0 # PyC thermal conductivity (W/m/K)

SiC_k = 13.9 # SiC thermal conductivity (W/m/K)

kernel_k = 3.5 # fissil kernel thermal conductivity (W/m/K)

matrix_k = 15.0 # graphite matrix thermal conductivity (W/m/K)

# operating conditions

inlet_T = 598.0 # inlet fluid temperature (K)

power = 30e3 # unit cell power (W)

mdot = 0.011 # fluid mass flowrate (kg/s)

# volume of the fuel compacts (six 1/3-compacts)

compact_vol = ${fparse 2 * pi * compact_diameter * compact_diameter / 4.0 * height}

# compute the volume fraction of each TRISO layer in a TRISO particle

# for use in computing average thermophysical properties

kernel_fraction = ${fparse kernel_radius^3 / oPyC_radius^3}

buffer_fraction = ${fparse (buffer_radius^3 - kernel_radius^3) / oPyC_radius^3}

ipyc_fraction = ${fparse (iPyC_radius^3 - buffer_radius^3) / oPyC_radius^3}

sic_fraction = ${fparse (SiC_radius^3 - iPyC_radius^3) / oPyC_radius^3}

opyc_fraction = ${fparse (oPyC_radius^3 - SiC_radius^3) / oPyC_radius^3}

# multiplicative factor on assumed heat source distribution to get correct magnitude

q0 = ${fparse power / (4.0 * height * compact_diameter * compact_diameter / 4.0)}

[Mesh]

[file]

type = FileMeshGenerator

file = mesh_in.e

[]

[]Next, we define the temperature variable, T, and specify the governing equations and boundary conditions we will apply.

[Variables]

[T]

initial_condition = ${inlet_T}

[]

[]

[Kernels]

[diffusion]

type = HeatConduction

variable = T

[]

[source]

type = CoupledForce

variable = T

v = power

block = 'compacts compacts_trimmer_tri'

[]

[]

[BCs]

[pin_outer]

type = MatchedValueBC

variable = T

v = fluid_temp

boundary = 'fluid_solid_interface'

[]

[]The MOOSE heat transfer module will receive power from OpenMC in the form of an AuxVariable, so we define a receiver variable for the fission power, as power. We also define a variable fluid_temp, that we will use a FunctionIC to set to the distribution in Eq. (2).

[AuxVariables]

[fluid_temp]

[]

[power]

family = MONOMIAL

order = CONSTANT

[]

[]

[ICs]

[fluid_temp]

type = FunctionIC

variable = fluid_temp

function = axial_fluid_temp

[]

[]We use functions to define the thermal conductivities and the fluid temperature. The thermal conductivity of the fuel compacts is computed as a volume average of the materials present.

[Functions]

[k_graphite]

type = ParsedFunction

expression = '${matrix_k}'

[]

[k_TRISO]

type = ParsedFunction

expression = '${kernel_fraction} * ${kernel_k} + ${buffer_fraction} * ${buffer_k} + ${fparse ipyc_fraction + opyc_fraction} * ${PyC_k} + ${sic_fraction} * ${SiC_k}'

[]

[k_compacts]

type = ParsedFunction

expression = '${triso_pf} * k_TRISO + ${fparse 1.0 - triso_pf} * k_graphite'

symbol_names = 'k_TRISO k_graphite'

symbol_values = 'k_TRISO k_graphite'

[]

[axial_fluid_temp]

type = ParsedFunction

expression = '${q0} * ${compact_vol} * (${height} - ${height} * cos(pi * z / ${height})) / pi / ${mdot} / ${fluid_Cp} + ${inlet_T}'

[]

[]

[Materials]

[graphite]

type = HeatConductionMaterial

thermal_conductivity_temperature_function = k_graphite

temp = T

block = 'graphite'

[]

[compacts]

type = HeatConductionMaterial

thermal_conductivity_temperature_function = k_compacts

temp = T

block = 'compacts compacts_trimmer_tri'

[]

[]We define a number of postprocessors for querying the solution as well as for normalizing the fission power, to be described at greater length in Neutronics Input Files .

[Postprocessors]

[max_fuel_T]

type = ElementExtremeValue

variable = T

value_type = max

block = 'compacts compacts_trimmer_tri'

[]

[max_block_T]

type = ElementExtremeValue

variable = T

value_type = max

block = 'graphite'

[]

[power]

type = ElementIntegralVariablePostprocessor

variable = power

block = 'compacts compacts_trimmer_tri'

execute_on = transfer

[]

[]Even though there are no time-dependent kernels in Eq. (1), we use a Transient such that each Picard iteration between OpenMC and MOOSE heat conduction is essentially one "pseduo" time step ("pseudo" because neither the OpenMC or solid model have any notion of time derivatives).

[Executioner]

type = Transient

nl_abs_tol = 1e-5

nl_rel_tol = 1e-16

petsc_options_value = 'hypre boomeramg'

petsc_options_iname = '-pc_type -pc_hypre_type'

[]

[Outputs]

exodus = true

csv = true

print_linear_residuals = false

[]Finally, for additional postprocessing we use a NearestPointLayeredAverage user object to perform averages in the x-y plane in 30 equal-size layers oriented in the z direction. We separate the average by blocks in order to compute separate averages for fuel and graphite temperatures. The layer-wise averages are then exported to the CSV output (in vector postprocessor form) by using two SpatialUserObjectVectorPostprocessors. Note that these user objects are strictly for visualization and generating the plot in Figure 6 - temperatures sent to OpenMC will be taken from the T variable.

[UserObjects]

[avg_power]

type = NearestPointLayeredAverage

variable = heat_source

points = '0.0 0.0 0.0'

num_layers = 30

direction = z

block = 'compacts compacts_trimmer_tri'

[]

[avg_std_dev]

type = NearestPointLayeredAverage

variable = heat_source_std_dev

points = '0.0 0.0 0.0'

num_layers = 30

direction = z

block = 'compacts compacts_trimmer_tri'

[]

[]

[VectorPostprocessors]

[avg_q]

type = SpatialUserObjectVectorPostprocessor

userobject = avg_power

[]

[stdev]

type = SpatialUserObjectVectorPostprocessor

userobject = avg_std_dev

[]

[]Neutronics Input Files

The neutronics physics is solved over the entire domain with OpenMC. The OpenMC wrapping is described in the openmc.i file. We begin by defining a number of constants and by setting up the mesh mirror on which OpenMC will receive temperature from the coupled MOOSE application, and on which OpenMC will write the fission heat source. Because the coupled MOOSE application uses length units of meters, the mesh mirror must also be in units of meters in order to obtain correct data transfers. For simplicity, we just use the same mesh used for solution of the solid heat conduction, though a different mesh could also be used.

height = 1.60 # height of the unit cell (m)

fluid_Cp = 5189.0 # fluid isobaric specific heat (J/kg/K)

inlet_T = 598.0 # inlet fluid temperature (K)

power = 30e3 # unit cell power (W)

mdot = 0.011 # fluid mass flowrate (kg/s)

[Mesh]

[solid]

type = FileMeshGenerator

file = mesh_in.e

[]

[]Next, for visualization purposes we define an auxiliary variable and apply a CellTemperatureAux in order to get the temperature imposed on the OpenMC cells. This auxiliary variable will then display the volume-averaged temperature mapped to the OpenMC cells.

[AuxVariables]

[cell_temperature]

family = MONOMIAL

order = CONSTANT

[]

[]

[AuxKernels]

[cell_temperature]

type = CellTemperatureAux

variable = cell_temperature

[]

[]The [Problem] and [Tallies] blocks are then used to specify settings for the OpenMC wrapping. We define a total power of 30 kW and add a CellTally to the fuel compacts. The cell tally setup in Cardinal will then automatically add a tally for each unique cell ID+instance combination. By setting temperature_blocks to all blocks, OpenMC will then receive temperature from MOOSE for the entire domain (because the mesh mirror consists of these three blocks). Importantly, note that the [Mesh] must always be in units that match the coupled MOOSE application. But because OpenMC solves in units of centimeters, we specify a scaling of 100, i.e. a multiplicative factor to apply to the [Mesh] to get into OpenMC's centimeter units.

[Problem]

type = OpenMCCellAverageProblem

power = ${power}

scaling = 100.0

temperature_blocks = 'graphite compacts compacts_trimmer_tri'

cell_level = 1

[Tallies]

[heat_source]

type = CellTally

name = heat_source

blocks = 'compacts compacts_trimmer_tri'

check_equal_mapped_tally_volumes = true

output = 'unrelaxed_tally_std_dev'

[]

[]

[]Other features we use include an output of the fission tally standard deviation in units of W/m3 to the [Mesh] by setting the output parameter. This is used to obtain the standard deviation of the heat source distribution from OpenMC in the same units as the heat source. We also leverage a helper utility in CellTally by setting check_equal_mapped_tally_volumes to true. This parameter will throw an error if the tallied OpenMC cells map to different volumes in the MOOSE domain. Because we know a priori that the equal-volume OpenMC tally cells should all map to equal volumes, this will help ensure that the volumes used for heat source normalization are also all equal. For further discussion of this setting and a pictorial description of the effect of non-equal mapped volumes, please see the OpenMCCellAverageProblem documentation.

Because the OpenMC model is formed by creating axial layers in a lattice nested one level below the highest universe level, the cell level is set to 1. Because the fuel compacts contain TRISO particles, this indicates that all cells in a fuel compact "underneath" level 1 will be set to the same temperature. Because the fuel compacts are homogenized in the heat conduction model, this multiphysics coupling is just an approximation to the true physics. Cardinal supports resolved TRISO multiphysics coupling, provided the solid mesh explicitly resolves the TRISO particles.

Because OpenMC is coupled by temperature to MOOSE, Cardinal automatically adds a variable named temp that will be an intermediate receiver of temperatures from MOOSE (before volume averaging by cell within OpenMCCellAverageProblem). We set an initial condition for temperature in OpenMC by setting a FunctionIC to temp with the function given by Eq. (2).

[ICs]

[temp]

type = FunctionIC

variable = temp

function = temp_ic

[]

[]

[Functions]

[temp_ic]

type = ParsedFunction

expression = '${inlet_T} + z / ${height} * ${power} / ${mdot} / ${fluid_Cp}'

[]

[]We run OpenMC as the main application, so we next need to define a MultiApp that will run the solid heat conduction model as the sub-application. We also require two transfers. To get the fission power into the solid model, we use a MultiAppShapeEvaluationTransfer and ensure conservation of the total power by specifying postprocessors to be preserved in the OpenMC wrapping (heat_source) and in the sub-application (power). To get the temperature into the OpenMC model, we also use a MultiAppShapeEvaluationTransfer in the reverse direction.

[MultiApps]

[solid]

type = TransientMultiApp

input_files = 'solid.i'

execute_on = timestep_end

[]

[]

[Transfers]

[heat_source_to_solid]

type = MultiAppGeneralFieldShapeEvaluationTransfer

to_multi_app = solid

variable = power

source_variable = heat_source

from_postprocessors_to_be_preserved = heat_source

to_postprocessors_to_be_preserved = power

[]

[temperature_to_openmc]

type = MultiAppGeneralFieldShapeEvaluationTransfer

from_multi_app = solid

variable = temp

source_variable = T

[]

[]We define a number of postprocessors to query the solution. The TallyRelativeError extracts the maximum fission tally relative error for monitoring active cycle convergence. The max_power and min_power ElementExtremeValue postprocessors compute the maximum and minimum fission power. And as already discussed, the heat_source postprocessor computes the total power for normalization purposes.

[Postprocessors]

[heat_source]

type = ElementIntegralVariablePostprocessor

variable = heat_source

execute_on = 'transfer initial timestep_end'

[]

[max_tally_rel_err]

type = TallyRelativeError

value_type = max

[]

[max_power]

type = ElementExtremeValue

variable = heat_source

value_type = max

block = 'compacts compacts_trimmer_tri'

[]

[min_power]

type = ElementExtremeValue

variable = heat_source

value_type = min

block = 'compacts compacts_trimmer_tri'

[]

[]We use a NearestPointLayeredAverage to radially average the OpenMC heat source and its standard deviation in axial layers across the 6 compacts. We output the result to CSV using SpatialUserObjectVectorPostprocessors. Note that this user object is strictly used for visualization purposes to generate the plot in Figure 4 - the heat source applied to the MOOSE heat conduction model is taken from the heat_source variable transferred with the heat_source_to_solid transfer.

[UserObjects]

[avg_power]

type = NearestPointLayeredAverage

variable = heat_source

points = '0.0 0.0 0.0'

num_layers = 30

direction = z

block = 'compacts compacts_trimmer_tri'

[]

[avg_std_dev]

type = NearestPointLayeredAverage

variable = heat_source_std_dev

points = '0.0 0.0 0.0'

num_layers = 30

direction = z

block = 'compacts compacts_trimmer_tri'

[]

[]

[VectorPostprocessors]

[avg_q]

type = SpatialUserObjectVectorPostprocessor

userobject = avg_power

[]

[stdev]

type = SpatialUserObjectVectorPostprocessor

userobject = avg_std_dev

[]

[]This input will run OpenMC and the MOOSE heat conduction model in Picard iterations via pseudo time-stepping. We specify a fixed number of time steps by running OpenMC with a Transient executioner. Finally, we specify Exodus and CSV output formats. Note, only four Picard iterations are shown here, but generally, more will be necessary to converge the physics.

[Executioner]

type = Transient

num_steps = 4

[]

[Outputs]

exodus = true

csv = true

[]Execution and Postprocessing

To run the coupled calculation,

mpiexec -np 2 cardinal-opt -i openmc.i --n-threads=2This will run both MOOSE and OpenMC with 2 MPI processes and 2 OpenMP threads per rank. When the simulation has completed, you will have created a number of different output files:

openmc_out.e, an Exodus file with the OpenMC solution and the data that was ultimately transferred in/out of OpenMCopenmc_out_solid0.e, an Exodus file with the solid solutionopenmc_out.csv, a CSV output with the postprocessors fromopenmc.iopenmc_out_solid0.csv, a CSV output with the postprocessors fromsolid.iopenmc_out_avg_q_<n>.csv, CSV output at time step<n>with the radially-averaged fission poweropenmc_out_stdev_<n>.csv, CSV output at time step<n>with the radially-averaged fission power standard deviationopenmc_out_solid0_block_axial_avg_<n>.csv, CSV output at time step<n>with the radially-average block temperatureopenmc_out_solid0_fuel_axial_avg_<n>.csv, CSV output at time step<n>with the radially-average fuel temperature

First, let's examine how the mapping between OpenMC and MOOSE was established. When we run with verbose = true, you will see the following mapping information displayed:

------------------------------------------------------------------------------------

| Cell | Solid | Fluid | Other | Mapped Vol | Actual Vol |

------------------------------------------------------------------------------------

| 11543, instance 0 (of 1) | 48 | 0 | 0 | 1.443e-06 | |

| 11544, instance 0 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11544, instance 1 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11544, instance 2 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11544, instance 3 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11544, instance 4 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11544, instance 5 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11545, instance 0 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11545, instance 1 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11545, instance 2 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11545, instance 3 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11545, instance 4 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11545, instance 5 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11547, instance 0 (of 1) | 48 | 0 | 0 | 1.443e-06 | |

| 11548, instance 0 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11548, instance 1 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11548, instance 2 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11548, instance 3 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11548, instance 4 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11548, instance 5 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11549, instance 0 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11549, instance 1 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11549, instance 2 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11549, instance 3 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11549, instance 4 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11549, instance 5 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11551, instance 0 (of 1) | 48 | 0 | 0 | 1.443e-06 | |

| 11552, instance 0 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11552, instance 1 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11552, instance 2 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11552, instance 3 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11552, instance 4 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11552, instance 5 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11553, instance 0 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11553, instance 1 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11553, instance 2 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11553, instance 3 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11553, instance 4 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11553, instance 5 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11555, instance 0 (of 1) | 48 | 0 | 0 | 1.443e-06 | |

| 11556, instance 0 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11556, instance 1 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11556, instance 2 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11556, instance 3 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11556, instance 4 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11556, instance 5 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11557, instance 0 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11557, instance 1 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11557, instance 2 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11557, instance 3 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11557, instance 4 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11557, instance 5 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11559, instance 0 (of 1) | 48 | 0 | 0 | 1.443e-06 | |

| 11560, instance 0 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11560, instance 1 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11560, instance 2 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11560, instance 3 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11560, instance 4 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11560, instance 5 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11561, instance 0 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11561, instance 1 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11561, instance 2 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11561, instance 3 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11561, instance 4 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11561, instance 5 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11563, instance 0 (of 1) | 48 | 0 | 0 | 1.443e-06 | |

| 11564, instance 0 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11564, instance 1 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11564, instance 2 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11564, instance 3 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11564, instance 4 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11564, instance 5 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11565, instance 0 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11565, instance 1 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11565, instance 2 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11565, instance 3 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11565, instance 4 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11565, instance 5 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11567, instance 0 (of 1) | 48 | 0 | 0 | 1.443e-06 | |

| 11568, instance 0 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11568, instance 1 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11568, instance 2 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11568, instance 3 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11568, instance 4 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11568, instance 5 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11569, instance 0 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11569, instance 1 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11569, instance 2 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11569, instance 3 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11569, instance 4 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11569, instance 5 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11571, instance 0 (of 1) | 48 | 0 | 0 | 1.443e-06 | |

| 11572, instance 0 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11572, instance 1 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11572, instance 2 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11572, instance 3 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11572, instance 4 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11572, instance 5 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11573, instance 0 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11573, instance 1 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11573, instance 2 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11573, instance 3 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11573, instance 4 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11573, instance 5 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11575, instance 0 (of 1) | 48 | 0 | 0 | 1.443e-06 | |

| 11576, instance 0 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11576, instance 1 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11576, instance 2 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11576, instance 3 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11576, instance 4 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11576, instance 5 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11577, instance 0 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11577, instance 1 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11577, instance 2 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11577, instance 3 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11577, instance 4 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11577, instance 5 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11579, instance 0 (of 1) | 48 | 0 | 0 | 1.443e-06 | |

| 11580, instance 0 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11580, instance 1 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11580, instance 2 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11580, instance 3 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11580, instance 4 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11580, instance 5 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11581, instance 0 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11581, instance 1 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11581, instance 2 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11581, instance 3 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11581, instance 4 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11581, instance 5 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11583, instance 0 (of 1) | 48 | 0 | 0 | 1.443e-06 | |

| 11584, instance 0 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11584, instance 1 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11584, instance 2 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11584, instance 3 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11584, instance 4 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11584, instance 5 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11585, instance 0 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11585, instance 1 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11585, instance 2 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11585, instance 3 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11585, instance 4 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11585, instance 5 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11587, instance 0 (of 1) | 48 | 0 | 0 | 1.443e-06 | |

| 11588, instance 0 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11588, instance 1 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11588, instance 2 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11588, instance 3 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11588, instance 4 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11588, instance 5 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11589, instance 0 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11589, instance 1 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11589, instance 2 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11589, instance 3 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11589, instance 4 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11589, instance 5 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11591, instance 0 (of 1) | 48 | 0 | 0 | 1.443e-06 | |

| 11592, instance 0 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11592, instance 1 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11592, instance 2 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11592, instance 3 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11592, instance 4 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11592, instance 5 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11593, instance 0 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11593, instance 1 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11593, instance 2 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11593, instance 3 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11593, instance 4 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11593, instance 5 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11595, instance 0 (of 1) | 48 | 0 | 0 | 1.443e-06 | |

| 11596, instance 0 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11596, instance 1 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11596, instance 2 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11596, instance 3 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11596, instance 4 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11596, instance 5 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11597, instance 0 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11597, instance 1 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11597, instance 2 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11597, instance 3 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11597, instance 4 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11597, instance 5 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11599, instance 0 (of 1) | 48 | 0 | 0 | 1.443e-06 | |

| 11600, instance 0 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11600, instance 1 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11600, instance 2 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11600, instance 3 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11600, instance 4 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11600, instance 5 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11601, instance 0 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11601, instance 1 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11601, instance 2 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11601, instance 3 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11601, instance 4 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11601, instance 5 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11603, instance 0 (of 1) | 48 | 0 | 0 | 1.443e-06 | |

| 11604, instance 0 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11604, instance 1 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11604, instance 2 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11604, instance 3 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11604, instance 4 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11604, instance 5 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11605, instance 0 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11605, instance 1 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11605, instance 2 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11605, instance 3 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11605, instance 4 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11605, instance 5 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11607, instance 0 (of 1) | 48 | 0 | 0 | 1.443e-06 | |

| 11608, instance 0 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11608, instance 1 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11608, instance 2 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11608, instance 3 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11608, instance 4 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11608, instance 5 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11609, instance 0 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11609, instance 1 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11609, instance 2 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11609, instance 3 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11609, instance 4 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11609, instance 5 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11611, instance 0 (of 1) | 48 | 0 | 0 | 1.443e-06 | |

| 11612, instance 0 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11612, instance 1 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11612, instance 2 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11612, instance 3 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11612, instance 4 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11612, instance 5 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11613, instance 0 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11613, instance 1 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11613, instance 2 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11613, instance 3 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11613, instance 4 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11613, instance 5 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11615, instance 0 (of 1) | 48 | 0 | 0 | 1.443e-06 | |

| 11616, instance 0 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11616, instance 1 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11616, instance 2 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11616, instance 3 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11616, instance 4 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11616, instance 5 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11617, instance 0 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11617, instance 1 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11617, instance 2 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11617, instance 3 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11617, instance 4 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11617, instance 5 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11619, instance 0 (of 1) | 48 | 0 | 0 | 1.443e-06 | |

| 11620, instance 0 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11620, instance 1 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11620, instance 2 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11620, instance 3 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11620, instance 4 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11620, instance 5 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11621, instance 0 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11621, instance 1 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11621, instance 2 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11621, instance 3 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11621, instance 4 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11621, instance 5 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11623, instance 0 (of 1) | 48 | 0 | 0 | 1.443e-06 | |

| 11624, instance 0 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11624, instance 1 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11624, instance 2 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11624, instance 3 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11624, instance 4 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11624, instance 5 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11625, instance 0 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11625, instance 1 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11625, instance 2 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11625, instance 3 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11625, instance 4 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11625, instance 5 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11627, instance 0 (of 1) | 48 | 0 | 0 | 1.443e-06 | |

| 11628, instance 0 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11628, instance 1 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11628, instance 2 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11628, instance 3 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11628, instance 4 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11628, instance 5 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11629, instance 0 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11629, instance 1 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11629, instance 2 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11629, instance 3 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11629, instance 4 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11629, instance 5 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11631, instance 0 (of 1) | 48 | 0 | 0 | 1.443e-06 | |

| 11632, instance 0 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11632, instance 1 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11632, instance 2 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11632, instance 3 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11632, instance 4 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11632, instance 5 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11633, instance 0 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11633, instance 1 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11633, instance 2 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11633, instance 3 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11633, instance 4 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11633, instance 5 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11635, instance 0 (of 1) | 48 | 0 | 0 | 1.443e-06 | |

| 11636, instance 0 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11636, instance 1 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11636, instance 2 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11636, instance 3 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11636, instance 4 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11636, instance 5 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11637, instance 0 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11637, instance 1 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11637, instance 2 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11637, instance 3 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11637, instance 4 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11637, instance 5 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11639, instance 0 (of 1) | 48 | 0 | 0 | 1.443e-06 | |

| 11640, instance 0 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11640, instance 1 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11640, instance 2 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11640, instance 3 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11640, instance 4 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11640, instance 5 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11641, instance 0 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11641, instance 1 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11641, instance 2 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11641, instance 3 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11641, instance 4 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11641, instance 5 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11643, instance 0 (of 1) | 48 | 0 | 0 | 1.443e-06 | |

| 11644, instance 0 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11644, instance 1 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11644, instance 2 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11644, instance 3 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11644, instance 4 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11644, instance 5 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11645, instance 0 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11645, instance 1 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11645, instance 2 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11645, instance 3 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11645, instance 4 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11645, instance 5 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11647, instance 0 (of 1) | 48 | 0 | 0 | 1.443e-06 | |

| 11648, instance 0 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11648, instance 1 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11648, instance 2 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11648, instance 3 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11648, instance 4 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11648, instance 5 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11649, instance 0 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11649, instance 1 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11649, instance 2 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11649, instance 3 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11649, instance 4 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11649, instance 5 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11651, instance 0 (of 1) | 48 | 0 | 0 | 1.443e-06 | |

| 11652, instance 0 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11652, instance 1 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11652, instance 2 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11652, instance 3 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11652, instance 4 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11652, instance 5 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11653, instance 0 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11653, instance 1 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11653, instance 2 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11653, instance 3 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11653, instance 4 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11653, instance 5 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11655, instance 0 (of 1) | 48 | 0 | 0 | 1.443e-06 | |

| 11656, instance 0 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11656, instance 1 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11656, instance 2 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11656, instance 3 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11656, instance 4 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11656, instance 5 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11657, instance 0 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11657, instance 1 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11657, instance 2 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11657, instance 3 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11657, instance 4 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11657, instance 5 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11659, instance 0 (of 1) | 48 | 0 | 0 | 1.443e-06 | |

| 11660, instance 0 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11660, instance 1 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11660, instance 2 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11660, instance 3 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11660, instance 4 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11660, instance 5 (of 6) | 68 | 0 | 0 | 2.252e-06 | |

| 11661, instance 0 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11661, instance 1 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11661, instance 2 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11661, instance 3 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11661, instance 4 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

| 11661, instance 5 (of 6) | 64 | 0 | 0 | 1.803e-06 | |

------------------------------------------------------------------------------------The cells with instances ranging from 0 to 5 represent the six fuel compacts and the graphite surrounding the fuel compacts (in those hex lattice positions). The other cells represent the single pure-graphite cell immediately hugging the coolant channel (the 0, 0 position in the hex lattice). Figure 4 shows the heat source computed by OpenMC on the mesh mirror (left) and radially averaged as a function of axial position (right). The error bars on the heat source are smaller than the marker size, so are not shown. Due to the negative temperature coefficient, the power distribution is shifted slightly downwards towards regions of lower temperature.

Figure 4: Heat source computed by OpenMC on the mesh mirror (left) and radially averaged as a function of axial position (right)

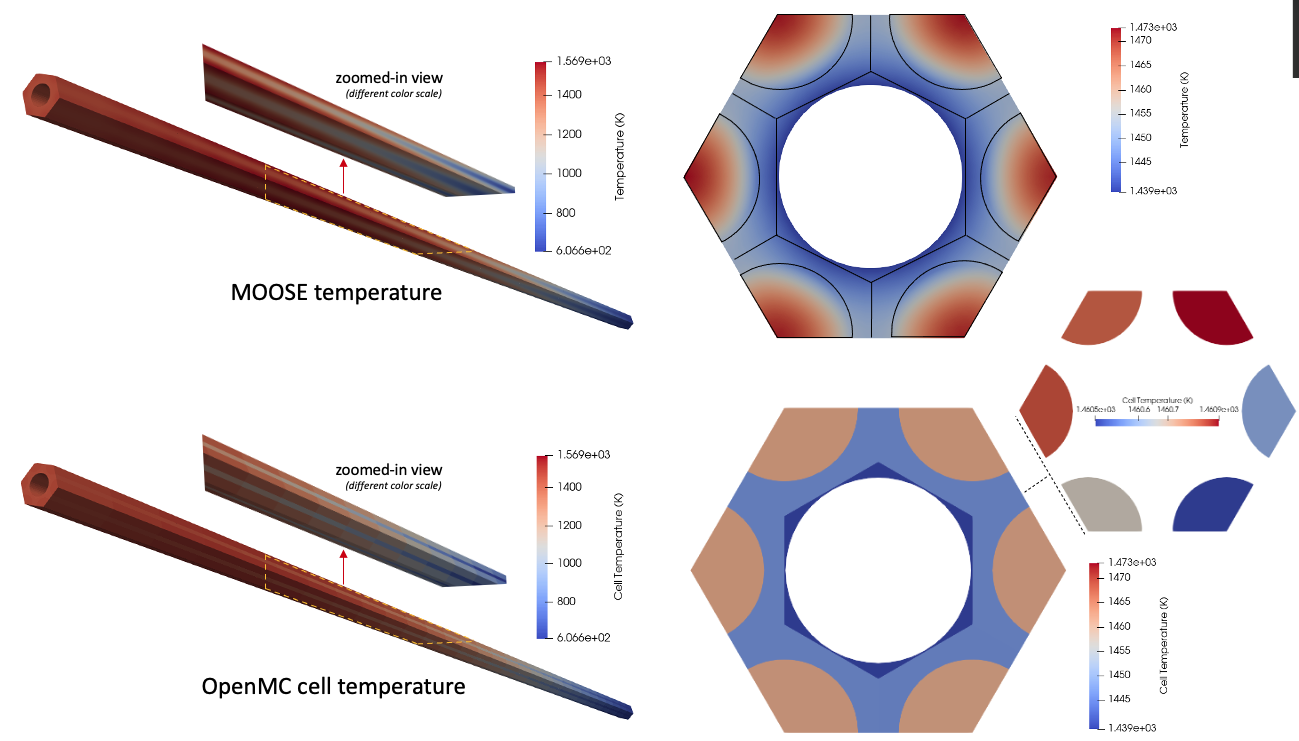

Figure 5 shows the temperature computed by MOOSE and the temperature applied to the OpenMC cells both as volume plots (left) and as slices at the top of the unit cell (right). In the volume plots, a zoomed-in view of the temperature near the midplane is shown on a different color scale to better illustrate the high temperatures in the compacts and the lower temperatures in the surrounding graphite block.

In the right image, black lines denote the boundaries of the OpenMC cells mapped to the solid domain. The inner hexagon enclosing the coolant channel is shown as the sage green color in Figure 3. For each unique cell ID+instance combination, a unique volume-average temperature is performed of the MOOSE solution according to the mapping of element centroids to the OpenMC cells. Therefore, on any given x-y plane, 38 temperatures are applied to the OpenMC model

one temperature for each of the fuel compacts (6)

one temperature for the graphite surrounding each fuel compact (6)

one temperature for the graphite surrounding the coolant channel (1)

The inset in the bottom right image in Figure 5 shows the temperatures imposed in each fuel compact, on a different color scale. Although the geometry contains several planes of symmetry, because we created unique tallies for each fuel compact (which have a small uncertainty of less than 1%), there are small asymmetries less than 0.4 K in magnitude in the temperature in the six compacts.

Figure 5: Temperature computed by MOOSE and applied to the OpenMC cells as volumes (left) and as slices at the top of the unit cell (right).

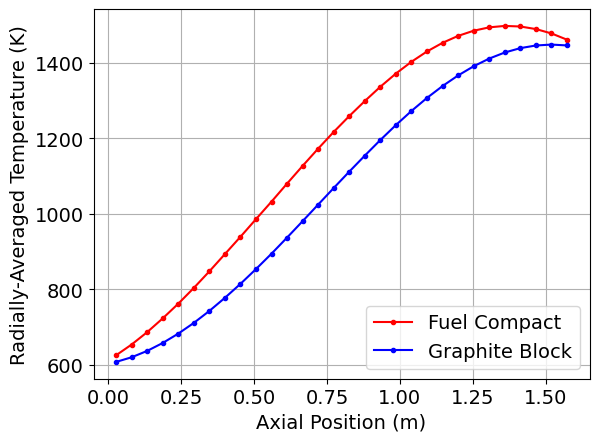

Figure 6 shows the fuel and graphite block temperatures as a function of axial position; each point is obtained by averaging over a slice parallel to the x-y plane. The graphite block temperature largely follows the imposed fluid temperature distribution, while the fuel compact temperature reaches a peak below the outlet because the fission power distribution is highest just slightly below the core mid-plane, as shown in Figure 4.

Figure 6: Radially-averaged fuel and graphite block temperatures in 30 axial layers

References

- INL.

High-Temperature Gas-Cooled Test Reactor Point Design.

Technical Report INL/EXT-16-38296, Idaho National Laboratory, 2016.

URL: https://tinyurl.com/v9a4hym5.[BibTeX]

@TechReport{sterbentz, author = "INL", title = "{High-Temperature Gas-Cooled Test Reactor Point Design}", institution = "Idaho National Laboratory", year = "2016", number = "INL/EXT-16-38296", url = "https://tinyurl.com/v9a4hym5" } - A.J. Novak, D. Andrs, P. Shriwise, J. Fang, H. Yuan, D. Shaver, E. Merzari, P.K. Romano, and R.C. Martineau.

Coupled Monte Carlo and Thermal-Fluid Modeling of High Temperature Gas Reactors Using Cardinal.

Annals of Nuclear Energy, 177:109310, 2022.

doi:10.1016/j.anucene.2022.109310.[BibTeX]

@Article{novak2022_cardinal, author = "Novak, A.J. and Andrs, D. and Shriwise, P. and Fang, J. and Yuan, H. and Shaver, D. and Merzari, E. and Romano, P.K. and Martineau, R.C.", title = "{Coupled {Monte} {Carlo} and Thermal-Fluid Modeling of High Temperature Gas Reactors Using {Cardinal}}", journal = "Annals of Nuclear Energy", year = "2022", volume = "177", pages = "109310", DOI = "10.1016/j.anucene.2022.109310" } - A.J. Novak, R.W. Carlsen, S. Schunert, P. Balestra, D. Reger, R.N. Slaybaugh, and R.C. Martineau.

Pronghorn: A Multidimensional Coarse-Mesh Application for Advanced Reactor Thermal Hydraulics.

Nuclear Technology, 2021.[BibTeX]

@Article{novak2021b, author = "Novak, A.J. and Carlsen, R.W. and Schunert, S. and Balestra, P. and Reger, D. and Slaybaugh, R.N. and Martineau, R.C.", title = "{Pronghorn: A Multidimensional Coarse-Mesh Application for Advanced Reactor Thermal Hydraulics}", journal = "Nuclear Technology", year = "2021" } - H. Petersen.

The Properties of Helium: Density, Specific Heats, Viscosity, and Thermal Conductivity at Pressures from 1 to 100 bar and from Room Temperature to about 1800 K.

Technical Report, Danish Atomic Energy Commission, 1970.[BibTeX]

@TechReport{petersen, author = "Petersen, H.", title = "{The Properties of Helium: Density, Specific Heats, Viscosity, and Thermal Conductivity at Pressures from 1 to 100 bar and from Room Temperature to about 1800 {K}}", institution = "Danish Atomic Energy Commission", year = "1970" }

(tutorials/gas_compact/mesh.i)

fuel_to_coolant_distance = 1.623e-2

compact_diameter = 1.27e-2

channel_diameter = 1.6e-2

height = 160e-2

n_layers = 30

ns = 8

[GlobalParams]

quad_center_elements = true

[]

[Mesh]

[fuel_pin]

type = PolygonConcentricCircleMeshGenerator

num_sides = 6

polygon_size = ${fparse fuel_to_coolant_distance / 2.0}

ring_radii = '${fparse 0.8 * compact_diameter / 2.0} ${fparse compact_diameter / 2.0}'

ring_intervals = '1 1'

num_sectors_per_side = '${ns} ${ns} ${ns} ${ns} ${ns} ${ns}'

ring_block_ids = '2 2'

ring_block_names = 'compacts compacts'

background_block_names = 'graphite'

background_intervals = 4

[]

[coolant_pin]

type = PolygonConcentricCircleMeshGenerator

num_sides = 6

polygon_size = ${fparse fuel_to_coolant_distance / 2.0}

ring_radii = '${fparse channel_diameter / 2.0}'

ring_intervals = '2'

num_sectors_per_side = '${ns} ${ns} ${ns} ${ns} ${ns} ${ns}'

ring_block_ids = '101 101'

ring_block_names = 'coolant coolant'

background_block_names = 'graphite'

interface_boundary_id_shift = 100

background_intervals = 1

[]

[bundle]

type = PatternedHexMeshGenerator

inputs = 'fuel_pin coolant_pin'

hexagon_size = ${fparse 2.0 * fuel_to_coolant_distance}

pattern = '0 0;

0 1 0;

0 0'

[]

[trim]

type = HexagonMeshTrimmer

input = bundle

trim_peripheral_region = '1 1 1 1 1 1'

peripheral_trimming_section_boundary = peripheral_section

[]

[rotate]

type = TransformGenerator

input = trim

transform = rotate

vector_value = '30.0 0.0 0.0'

[]

[extrude]

type = AdvancedExtruderGenerator

input = rotate

heights = ${height}

num_layers = ${n_layers}

direction = '0 0 1'

[]

[fluid_solid_interface]

type = SideSetsBetweenSubdomainsGenerator

input = extrude

primary_block = 'graphite'

paired_block = 'coolant'

new_boundary = 'fluid_solid_interface'

[]

[delete_coolant]

type = BlockDeletionGenerator

input = fluid_solid_interface

block = 'coolant'

[]

[]

# The following content is adding postprocessor(s) to check sideset areas.

# The reactor module is unfortunately quite brittle in its assignment of sideset

# IDs, so we want to be extra sure that any changes to sideset numbering are detected

# in our test suite.

[Problem]

type = FEProblem

solve = false

[]

[Postprocessors]

[area_walls] # should approximate 0.08042477193189872

type = AreaPostprocessor

boundary = 'fluid_solid_interface'

[]

[volume_fuel] # should approximate 0.0004053659832779982

type = VolumePostprocessor

block = 'compacts compacts_trimmer_tri'

[]

[]

[Executioner]

type = Steady

[]

[Outputs]

csv = true

[](tutorials/gas_compact/unit_cell.py)

#!/bin/env python

#********************************************************************/

#* SOFTWARE COPYRIGHT NOTIFICATION */

#* Cardinal */

#* */

#* (c) 2021 UChicago Argonne, LLC */

#* ALL RIGHTS RESERVED */

#* */

#* Prepared by UChicago Argonne, LLC */

#* Under Contract No. DE-AC02-06CH11357 */

#* With the U. S. Department of Energy */

#* */

#* Prepared by Battelle Energy Alliance, LLC */

#* Under Contract No. DE-AC07-05ID14517 */

#* With the U. S. Department of Energy */

#* */

#* See LICENSE for full restrictions */

#********************************************************************/

from argparse import ArgumentParser

import math

import numpy as np

import matplotlib.pyplot as plt

import openmc

outlet_P = 7.1e6 # fluid outlet pressure (Pa)

inlet_T = 598.0 # inlet fluid temperature (K)

power = 30e3 # unit cell power (W)

mdot = 0.011 # fluid mass flowrate (kg/s)

fluid_Cp = 5189.0 # fluid isobaric specific heat (J/kg/K)

channel_diameter = 0.016 # diameter of the coolant channels (m)

compact_diameter = 0.0127 # diameter of fuel compacts (m)

fuel_to_coolant_distance = 0.01628 # distance between center of fuel compact and coolant channel (m)

height = 1.60 # height of the unit cell (m)

triso_pf = 0.15 # TRISO packing fraction (%)

kernel_radius = 214.85e-6 # fissile kernel outer radius (m)

buffer_radius = 314.85e-6 # buffer outer radius (m)

iPyC_radius = 354.85e-6 # inner PyC outer radius (m)

SiC_radius = 389.85e-6 # SiC outer radius (m)

oPyC_radius = 429.85e-6 # outer PyC outer radius (m)

enrichment = 0.155 # fuel enrichment (weight percent)

kernel_density = 10820 # fissile kernel density (kg/m3)

buffer_density = 1050 # buffer density (kg/m3)

PyC_density = 1900 # PyC density (kg/m3)

SiC_density = 3203 # SiC density (kg/m3)

matrix_density = 1700 # graphite matrix density (kg/m3)

def coolant_temp(t_in, t_out, l, z):

"""

THIS IS ONLY USED FOR SETTING AN INITIAL CONDITION IN OPENMC's XML FILES -

the coolant temperature will be applied from MOOSE, we just set an initial

value here in case you want to run these files in standalone mode (i.e. with

the "openmc" executable).

Computes the coolant temperature based on an expected cosine power distribution

for a specified temperature rise. The total core temperature rise is governed

by energy conservation as dT = Q / m / Cp, where dT is the total core temperature

rise, Q is the total core power, m is the mass flowrate, and Cp is the fluid

isobaric specific heat. If you neglect axial heat conduction and assume steady

state, then the temperature rise in a layer of fluid i can be related to the

ratio of the power in that layer to the total power,

dT_i / dT = Q_i / Q. We assume here a sinusoidal power distribution to get

a reasonable estimate of an initial coolant temperature distribution.

Parameters

----------

t_in : float

Inlet temperature of the channel

t_out : float

Outlet temperature of the channel

l : float

Length of the channel

z : float or 1-D numpy.array

Axial position where the temperature will be computed

Returns

-------

float or 1-D numpy array of float depending on z

"""

dT = t_out - t_in

Q = 2 * l / math.pi

Qi = (l - l * np.cos(math.pi * z / l)) / math.pi

t = t_in + Qi / Q * dT

return t

def coolant_density(t):

"""

THIS IS ONLY USED FOR SETTING AN INITIAL CONDITION IN OPENMC's XML FILES -

the coolant density will be applied from MOOSE, we just set an initial

value here in case you want to run these files in standalone mode (i.e. with

the "openmc" executable).

Computes the helium density (kg/m3) from temperature assuming a fixed operating pressure.

Parameters

----------

t : float

Fluid temperature

Returns

_______

float or 1-D numpy array of float depending on t

"""

p_in_bar = outlet_P * 1.0e-5

return 48.14 * p_in_bar / (t + 0.4446 * p_in_bar / math.pow(t, 0.2))

# -------------- Unit Conversions: OpenMC requires cm -----------

m = 100.0

# -------------------------------------------

### RADIANT UNIT CELL SPECS (INFERRED FROM REPORTS) ###

# estimate the outlet temperature using bulk energy conservation for steady state

coolant_outlet_temp = power / mdot / fluid_Cp + inlet_T

# geometry

coolant_channel_diam = channel_diameter * m

reactor_bottom = 0.0

reactor_height = height * m

reactor_top = reactor_bottom + reactor_height

### ARBITRARILY DETERMINED PARAMETERS ###

cell_pitch = fuel_to_coolant_distance * m

fuel_channel_diam = compact_diameter * m

hex_orientation = 'x'

def unit_cell(n_ax_zones, n_inactive, n_active, add_entropy_mesh=False):

axial_section_height = reactor_height / n_ax_zones

# superimposed search lattice

triso_lattice_shape = (4, 4, int(axial_section_height / 0.125))

lattice_orientation = 'x'

cell_edge_length = cell_pitch

model = openmc.model.Model()

### Materials ###

enrichment_234 = 2e-3

# TRISO Materials