DAGMC pincell

In this tutorial, you will learn how to:

Couple CAD Monte Carlo models via temperature and heat source feedback to MOOSE

To access this tutorial,

To run this tutorial, you need to have built Cardinal with DAGMC support enabled, by setting export ENABLE_DAGMC=true.

Geometry and Computational Models

This model consists of a pincell, taken directly from an OpenMC DAGMC tutorial. Direct Accelerated Geometry Monte Carlo (DAGMC) is a package for Monte Carlo transport on Computer Aided Design (CAD) geometry. We will not go into detail on how the DAGMC model was generated, but instead refer you to the DAGMC documentation.

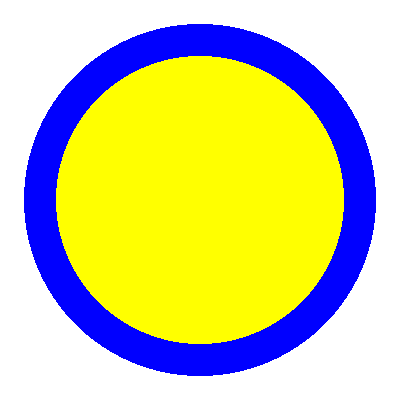

The geometry consists of a U-235 cylinder enclosed in an annulus of water. The height is 40 cm, and the outer diameter of the fuel cylinder is 18 cm. The total power is set to 1000 W. An image of the geometry is shown on the - plane in Figure 1.

Figure 1: OpenMC DAGMC geometry colored by material, on the - plane.

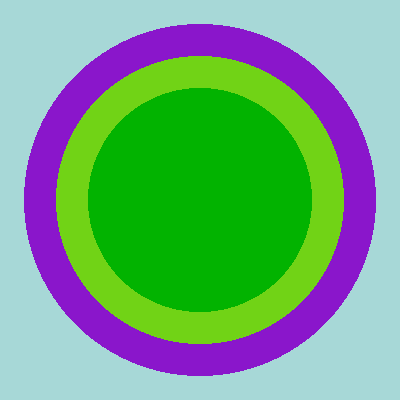

Figure 2 shows the same DAGMC model, colored instead by cell. The two green regions are both U-235, while the purple is water. There is no particular reason why the model is built this way, since we are just fetching it from an existing OpenMC tutorial.

Figure 2: OpenMC DAGMC geometry colored by cell, on the - plane.

MOOSE Heat Conduction Model

The MOOSE heat transfer module is used to solve for steady-state heat conduction,

(1)

where is the solid thermal conductivity, is the solid temperature, and is a volumetric heat source in the solid.

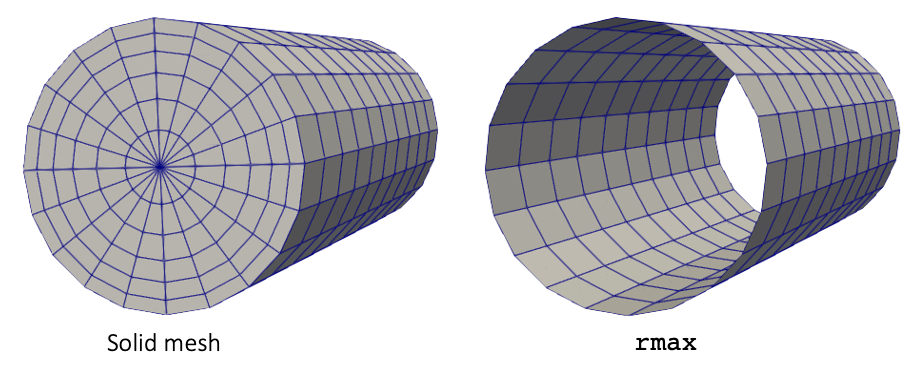

MeshGenerators are used to construct the solid mesh. Figure 3 shows the solid mesh with block IDs and sidesets. We will not model any heat transfer in the water region, for simplicity. Different block IDs are used for the hexahedral and prism elements in the pellet region because libMesh does not allow different element types to exist on the same block ID. To generate the mesh,

Figure 3: Mesh for the solid portions of a pincell

The surface of the pincell is simply set to a constant value, . Because heat transfer and fluid flow in the borated water is not modeled in this example, The top and bottom of the solid pincell are assumed insulated. In this example, the MOOSE heat transfer module will run first. The initial solid temperature is 500°C and the initial power is zero.

OpenMC Model

The OpenMC model is built using DAGMC. Particles move through space with surface-to-surface tracking between triangle surface meshes. Cells are the regions of space enclosed by these surfaces. After building the DAGMC model with Cubit, we set up the OpenMC input files using the Python API. First, we define materials, then fetch the geometry from the DAGMC geometry file (dagmc.h5m). Then, we set up the settings, for numbers of batches and particles, and how we would like to have temperature feedback applied to OpenMC.

To generate the XML files needed to run OpenMC, you can run the following:

or simply use the XML files checked in to the tutorials/dagmc directory.

Multiphysics Coupling

In this section, OpenMC and MOOSE are coupled for heat source and temperature feedback for a DAGMC pincell. The following sub-sections describe these files.

Solid Input Files

The solid phase is solved with the MOOSE heat transfer module, and is described in the solid.i input. The solid mesh is created using mesh generators in the mesh.i input:

We generate the mesh by running cardinal-opt -i mesh.i --mesh-only to create the mesh_in.e file, which we then use in the solid input file.

The heat transfer module will solve for temperature, with the heat equation. The variables, kernels, and boundary conditions are shown below.

(tutorials/dagmc/solid.i)The Transfer system in MOOSE is used to communicate variables across applications; a heat source will be computed by OpenMC and applied as a source term in MOOSE. In the opposite direction, MOOSE will compute a temperature that will be applied to the OpenMC geometry. The heat_source auxiliary variable will simply receive the heat source from OpenMC. The MultiApps and Transfers blocks describe the interaction between Cardinal and MOOSE. The MOOSE heat conduction application is run as the main application, with OpenMC run as the sub-application. We specify that MOOSE will run first on each time step.

Two transfers are required to couple OpenMC and MOOSE for heat source and temperature feedback. The first is a transfer of heat source from Cardinal to MOOSE. The second is transfer of temperature from MOOSE to Cardinal.

(tutorials/dagmc/solid.i)For the heat source transfer from OpenMC, we ensure conservation by requiring that the integral of heat source computed by OpenMC (in the heat_source postprocessor) matches the integral of the heat source received by MOOSE (in the source_integral postprocessor). We also add a postprocessor to evaluate the maximum solid temperature.

Because we did not specify sub-cycling in the [MultiApps] block, this means that OpenMC will run for exactly the same number of time steps (but the actual time step size used by the OpenMC wrapping is of no consequence because OpenMC is run in -eigenvalue mode). By setting a fixed number of time steps, this example will simply run a fixed number of Picard iterations.

Neutronics Input Files

The neutronics physics is solved over the entire domain using OpenMC. The OpenMC wrapping is described in the openmc.i input file. We begin by defining a mesh on which OpenMC will receive temperature from the coupled MOOSE application, and on which OpenMC will write the fission heat source. In this example, we use exactly the same solid mesh as the coupled MOOSE application; this is not a requirement, and is relaxed in other tutorials.

Next, the Problem and Tallies blocks describe all objects necessary for the actual neutronics solve. To replace MOOSE finite element calculations with OpenMC particle transport calculations, the OpenMCCellAverageProblem class is used.

(tutorials/dagmc/openmc.i)For this example, we specify the total fission power by which to normalize OpenMC's tally results (because OpenMC's tally results are in units of eV/source particle). Next, we indicate which blocks in the [Mesh] should be considered for temperature feedback using temperature_blocks. Here, we specify temperature feedback for the pellet (blocks 2 and 3). During the initialization, OpenMCCellAverageProblem will automatically map from MOOSE elements to OpenMC cells, and store which MOOSE elements are providing temperature feedback. Then when temperature is sent into OpenMC, that mapping is used to compute a volume-average temperature to apply to each OpenMC cell.

This example uses mesh tallies, as indicated by the MeshTally in the [Tallies] block. OpenMCCellAverageProblem will then automatically add the OpenMC mesh tally using the information provided. Finally, we specify the level in the geometry on which the cells exist. Because we don't have any lattices or filled universes in our OpenMC model, the cell level is zero.

At this point, it is important to remind ourselves of the problem setup. OpenMC is tracking particles with surface-to-surface tracking for a tetrahedral mesh (the dagmc.h5m geometry). However, the [Mesh] block is just overlaid on the problem, and we tally on this separate mesh. The two meshes (the tally mesh in the [Mesh] block vs. the DAGMC mesh) are completely unrelated to one another.

Next, we add a series of auxiliary variables for solution visualization (these are not requried for coupling). To help with understanding how the OpenMC model maps to the mesh in the [Mesh] block, we add auxiliary variables to visualize OpenMC's cell temperature (CellTemperatureAux). Cardinal will also automatically output a variable named cell_id (CellIDAux) and a variable named cell_instance ( CellInstanceAux) to show the spatial mapping.

Next, we specify an executioner and output settings. Even though OpenMC technically performs a criticality calculation (with no time dependence), we use the transient executioner so that if we wanted to run OpenMC more times than the coupled main application via subcycling, we would have a way to control that.

(tutorials/dagmc/openmc.i)Finally, we add a postprocessor to evaluate the total heat source computed by OpenMC and query other parts of the solution.

(tutorials/dagmc/openmc.i)Execution and Postprocessing

To run the coupled calculation,

This will run both MOOSE and OpenMC with 2 MPI processes and 2 OpenMP threads per rank. To run the simulation faster, you can increase the parallel processes/threads, or simply decrease the number of particles used in OpenMC. When the simulation has completed, you will have created a number of different output files:

solid_out.e, an Exodus output with the solid mesh and solutionsolid_out_openmc0.e, an Exodus output with the OpenMC solution and the data that was ultimately transferred in/out of OpenMC

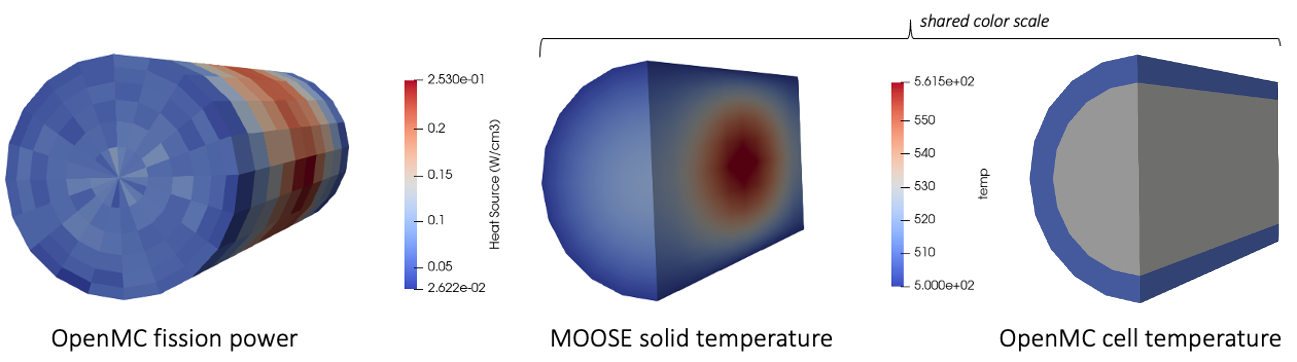

Figure 4 shows the heat source computed by OpenMC (units of W/cm) and mapped to the MOOSE mesh, the solid temperature computed by MOOSE, and the temperature imposed in OpenMC. The two images showing temperature share a color scale, and are depicted as a slice through the pellet. Because the DAGMC model only has two cells to represent the fuel region, the temperature imposed in OpenMC is a volume average over the elements corresponding to each of those two cells. If you want to resolve the solid temperature with more detail in the OpenMC model, simply add OpenMC cells where finer feedback is desired - or, you can adaptively re-generate the OpenMC cells using the MoabSkinner.

Figure 4: Heat source (W/cm) computed by OpenMC (left); MOOSE solid temperature (middle); OpenMC cell temperature (right)