Adaptive Mesh Refinement on Mesh Tallies

In this tutorial, you will learn how to:

Couple OpenMC to MOOSE (via a heat source) for a single assembly in the C5G7 LWR reactor physics benchmark

Generate assembly meshes using the MOOSE Reactor module

Enable Adaptive Mesh Refinement (AMR) on an unstructured mesh tally to automatically refine the heat source

To access this tutorial,

The full assembly case requires HPC due to the number of elements in the tally mesh, both before and after the application of AMR. You can run the OpenMC problem with a reduced number of particles, however the mesh may not refine due to the large tally relative errors caused by poor stastistics. We include a section on running AMR on a single pin of the assembly mesh if you don't have access to HPC resources - this example can be found in Single Pincell.

Geometry and Computational Models

This model consists of a single UO assembly from the 3D C5G7 extension case in Smith et al. (2006), where control rods are fully inserted in the assembly to induce strong axial and radial gradients. Instead of using the multi-group cross sections from the C5G7 benchmark specifications, the material properties in Cathalau et al. (1996) are used. At a high level the geometry consists of the following lattice elements in a 17x17 grid:

264 fuel pins composed of UO pellets clad in zirconium with a helium gap;

24 control rods composed of BC pellets clad in aluminum, with no gap, occupying the assembly guide tubes;

A single fission chamber in the central guide tube composed of borated water, with a trace amount of U-235, clad in aluminum with no gap.

The remainder of the assembly not filled with these pincells is composed of borated water. Above the top of the fuel, there is a reflector region which is penetrated by the inserted control rods. The relevant dimensions can be found in Table 1.

Table 1: Geometric specifications for a rodded LWR assembly

| Parameter | Value (cm) |

|---|---|

| Fuel pellet outer radius | 0.4095 |

| Fuel clad inner radius | 0.418 |

| Fuel clad outer radius | 0.475 |

| Control rod outer radius | 0.3400 |

| Fission chamber outer radius | 0.3400 |

| Guide tube clad outer radius | 0.54 |

| Pin pitch | 1.26 |

| Fuel height | 192.78 |

| Reflector thickness | 21.42 |

A total core power of 3000 MWth is assumed uniformly distributed among 273 rodded fuel assemblies, each with 264 pins (which do not have a uniform power distribution due to the control rods). The unstructured mesh tallies added by Cardinal will therefore be normalized according to the per-assembly power:

(1)

where is the number of fuel assemblies in the core.

OpenMC Model

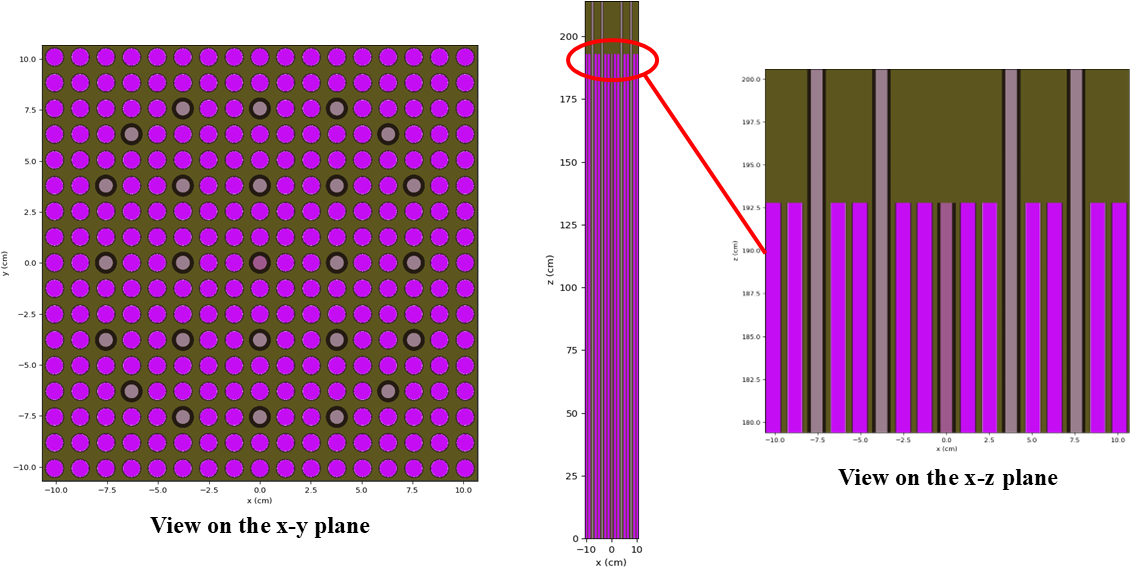

OpenMC's Python API is used to generate the Constructive Solid Geometry (CSG) model for this LWR assembly. We begin by defining the geometric specification of the assembly. This is followed by the creation of materials for each of the regions described in the previous section, where the helium gap is assumed to be well represented by a void region. We then define the geometry for each pincell (fuel, control rod in guide tube, fission chamber, reflector water) which are used to define the 17x17 lattice for both the active fuel region and the reflector. The sides and bottom of the assembly use reflective boundary conditions while the top of the assembly uses a vacuum boundary condition (in other words, we are modeling only half the axial extent of the bundle). The OpenMC model can be found in Figure 1. The Python script used to generate the model.xml file can be found below.

Figure 1: OpenMC geometry colored by material ID shown on the - and - planes

To generate the XML files needed to run OpenMC, you can run the following:

Or you can use the model.xml file that is included in the tutorials/lwr_amr directory.

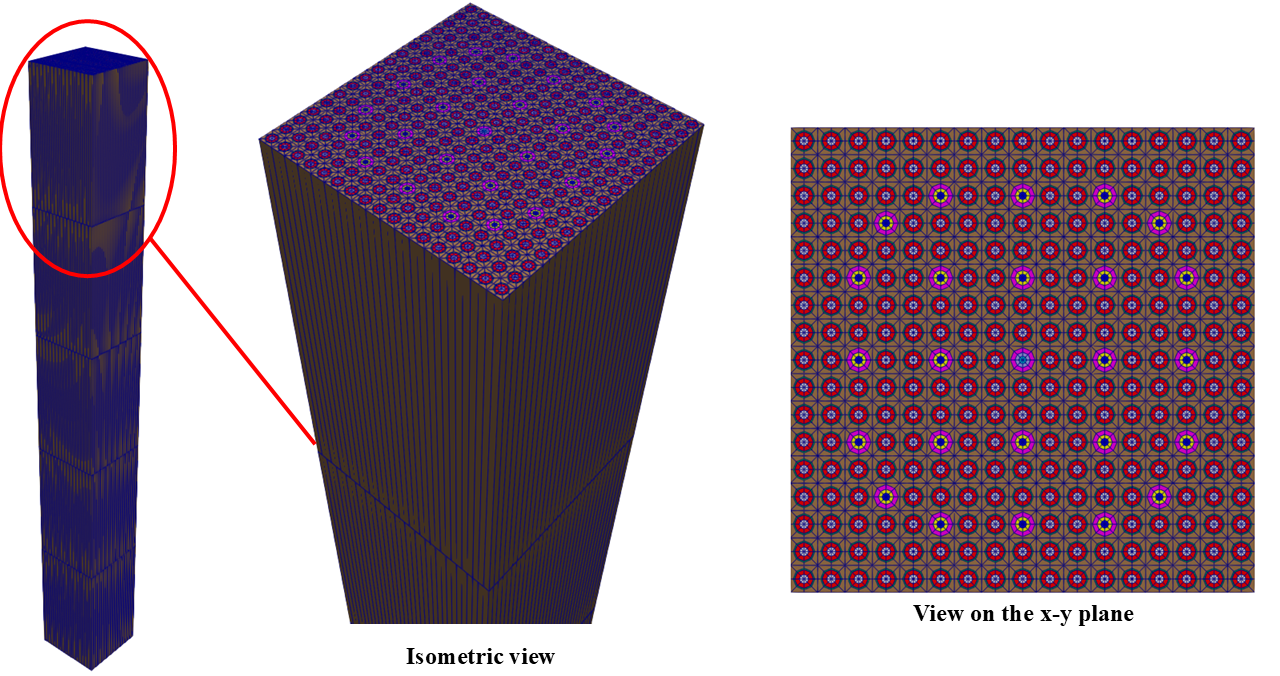

Mesh Generation with the Reactor Module

The mesh used to tally the fission heating in this problem will be generated using the MOOSE Reactor module, which provides a suite of mesh generators suited for common fission reactor geometries. We begin by defining the geometric properties of the assembly (as described in Table 1) followed by some discretization parameters. NUM_SECTORS is the number of azimuthal discretization regions per for a quadrant of the pincell, FUEL_RADIAL_DIVISIONS is the number of radial regions we use for subdividing the fuel, BACKGROUND_DIVISIONS is the number of radial subdivisions for the water bounding box, and AXIAL_DIVISIONS is the number of subdivisions we use when extruding the geometry into 3D.

After defining the geometric properties and discretization parameters we define the four different pincells in the [Mesh] block using the PolygonConcentricCircleMeshGenerator - the workhorse of the Reactor module. We set preserve_volumes = true in an attempt to preserve the volume of each region, which ensures that our tallied volumetric fission power is consistent with the OpenMC geometry.

After defining each pincell, these distinct regions are combined into a 2D assembly mesh using a PatternedCartesianMeshGenerator.

(tutorials/lwr_amr/mesh.i)The fuel-cladding gap blocks are deleted after the assembly mesh is generated - this is due to these regions being modelled as voids in OpenMC and so they will not receive any tallies (in other words, we are simply reducing some memory needed to keep unused parts of the mesh, though you could certainly keep those mesh blocks if you desired). We finish the mesh generation process by translating the assembly mesh such that its center is located at the origin, and extrude the geometry from the fuel centerline to the top of the active fuel region.

(tutorials/lwr_amr/mesh.i)We generate the mesh by running the command below, which creates the mesh_in.e file that is used in the Cardinal input file for volumetric tallies. The final mesh can be found in Figure 2, which is a fairly coarse mesh in the axial direction. We will rely on AMR to refine both the radial and axial power distribution.

Figure 2: Initial tally mesh colored by block ID, shown in an isometric view and sliced on the plane

Neutronics Input File

The neutronics calculation is performed over the entire assembly by OpenMC, and the wrapping of the OpenMC results in MOOSE is performed in openmc.i. We begin by defining the mesh which will be used by OpenMC to tally the volumetric fission power, which we generated in the previous step:

Next, the Problem and Tallies blocks describe all of the syntax necessary to replace the normal MOOSE finite element calculation with an OpenMC neutronics solve. This is done with an OpenMCCellAverageProblem.

(tutorials/lwr_amr/openmc.i)We specify the number of particles to use alongside the assembly power to normalize tally results. We set normalize_by_global_tally = false as the unstructured mesh tally does not perfectly represent the CSG geometry, and so some scores will be missed compared to a global tally. assume_separate_tallies and skip_statepoint are set to true as performance optimizations. A MeshTally is added in the [Tallies] block which will automatically score on mesh_in.e. This tally scores kappa_fission to a MOOSE variable named heat_source while also calculating the standard deviation of the tally field (stored in heat_source_std_dev). We specify that we only wish to tally on the fueled regions (uo2_center and uo2) as the remainder of the assembly will accumulate zero (or near-zero in the case of the fission chamber) tally scores for fission heating.

A steady-state executioner is selected as OpenMC will run a single criticality calculation. We then select exodus and CSV output (for our postprocessors) which will occur on the end of the simulation.

(tutorials/lwr_amr/openmc.i)Finally, we add three TallyRelativeError postprocessors to evaluate the minimum, maximum, and average tally relative error of the kappa_fission score. These are useful for determining if the number of batches need to be increased when increasing the mesh resolution using AMR.

Execution and Postprocessing

To run the wrapped neutronics calculation,

This will run OpenMC with 4 MPI ranks with 32 OpenMP threads per rank. To run the simulation faster, you can increase the parallel processes/threads, or simply decrease the number of particles used in OpenMC. When the simulation has completed, you will have created a number of different output files:

openmc_out.e: an Exodus mesh with the tally results;openmc_out.csv: a CSV file with the results reported by the TallyRelativeError postprocessors.

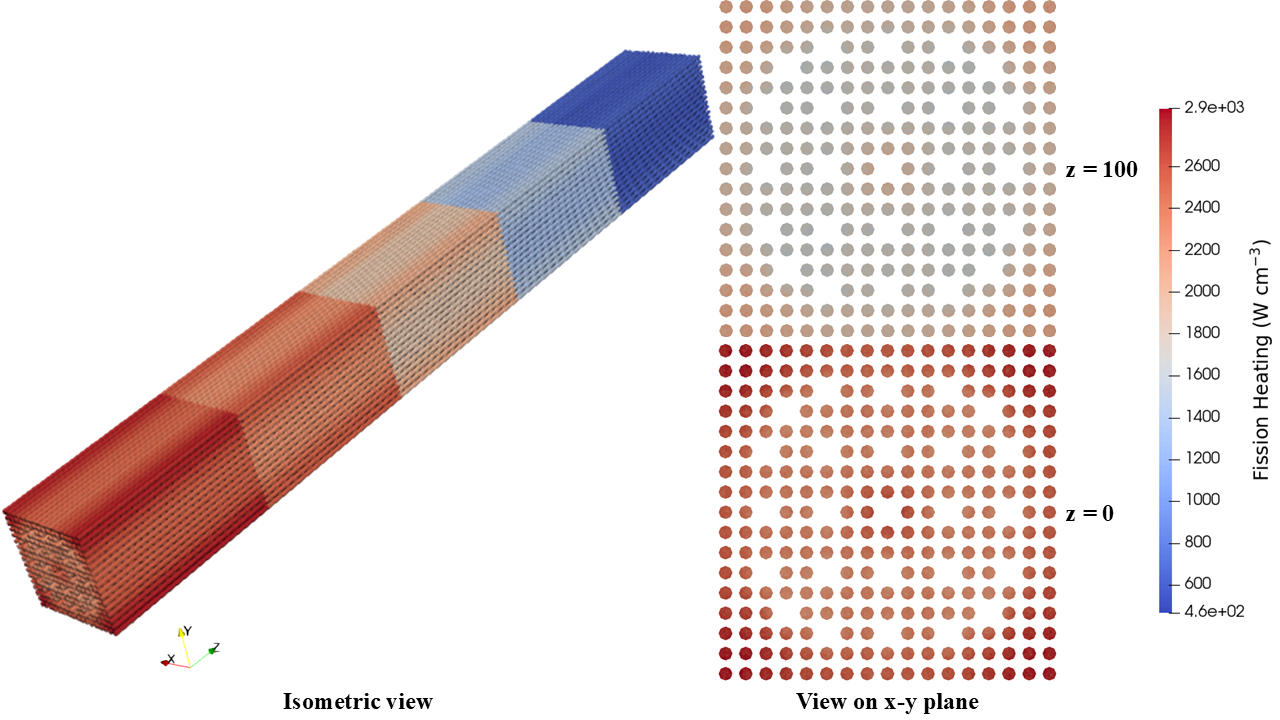

Figure 3 shows the resulting fission power computed by OpenMC on the mesh tally added by Cardinal. We can see that the radial power distribution peaks near the corners of the assembly (due to the reflective boundary conditions), and is depressed near the guide tubes due to the insertion of the control rods. The center of the assembly sees some additional power peaking due to the fission chamber. The power distribution within the assembly begins to decrease along the z-axis as one moves from the assembly centerline to the vacuum boundary condition. The coarse axial discretization makes it difficult to determine if this follows the standard cosine shape, and the lack of radial refinement fails to capture gradients within each pincell. This motivates the use of AMR to automatically refine the tally mesh.

To add AMR, we add two sub-blocks. The first is the Indicators block, members of which are responsible for computing estimates of the spatial solution error for each element in the mesh. The second is the Markers block, members of which take error estimates from indicators and use them to determine if an element should be isotropically refined or coarsened.

Figure 3: Fission power computed with the unstructured mesh tally, shown with an isometric view and sliced on the plane

Adding Adaptive Mesh Refinement

Next, we will adaptively refine the mesh using the adaptivity system included in MOOSE. The Cardinal input file for adaptivity is largely the same as the input file for the initial mesh tally - it can be found in openmc_amr.i. The main difference between openmc.i and openmc_amr.i is the addition of the Adaptivity block (shown below), which is responsible for determining the refinement / coarsening behaviour of the mesh. The adaptivity block consists of two sub-blocks: Indicators which compute estimates of spatial discretization error, and Markers which use these error estimates to mark elements for refinement or coarsening. Two steps of mesh adaptivity are selected with steps = 2, and error_combo is selected to be the marker to use when modifying the mesh.

In this adaptivity block we define a single indicator which assumes that the spatial error in an element is proportional to the mean optical depth within the element (optical_depth). This indicator requires a tally score to use for computing the energy-integrated reaction rate in an element - we select the fission reaction rate as we aim to optimize the spatial distribution of fission heating. It also requires an estimate of the mean chord length in the element (h_type) which we set to the maximum vertex separation in an element due to the coarse axial discretization in our initial mesh.

We then add three markers, the first of which is a ErrorFractionMarker (depth_frac) which takes optical_depth as an input. This marker sorts all elements into descending order based on the indicator value, then iterates over the list (starting with the largest error estimate). Elements whose optical depth sum to a refinement fraction multiplied by the total error estimate are refined. The list is iterated in reverse to mark elements for coarsening. We set the refinement fraction refine = 0.3, while setting the coarsening threshold coarsen = 0.0. The next marker we add is a ValueThresholdMarker (rel_error), which marks elements for refinement if their value is above refine and marks elements to be coarsened if their value is above coarsen. We pass it the variable containing the relative error of the fission heating (variable = heat_source_rel_error) and set invert = true. This has the effect of marking an element for coarsening if the fission heating relative error is above 1e-1, while allowing refinement of the relative error of the fission heating relative error is below 5e-2. We set third_state = DO_NOTHING to indicate that elements in this region should not be refined or coarsened. The final marker we add is a BooleanComboMarker (error_combo) which combines the previous two markers based on a flag in boolean_operator. refine_markers = 'rel_error depth_frac' with the and boolean flag results in refinement only when the element is marked based on it's fraction of the optical depth and has a sufficiently low statistical relative error. coarsen_markers = 'rel_error' results in coarsening only if the element has a sufficiently hight statistical relative error.

The remaining modifications that need to be made are done to support [Adaptivity]. We modify heat_source to also score flux and fission to allow for the calculation of the optical depth. This also necessitates the specification of source_rate_normalization = 'kappa_fission' as two non-heating scores have been added. unrelaxed_tally_rel_error is added to the output parameter to enable the rel_error marker. The modifications to the [Problem] and [Tallies] block can be found below.

The final change we make is to add an extra postprocessor named num_elem to output the number of elements. This postprocessor filters for the number of active elements, which are the elements currently being tallied on. This is distinct from the total number of elements as MOOSE/libMesh maintains the entire refinement hierarchy, and so elements which aren't participating in the solve at the current refinement cycle still exist in memory (and therefore are included in the total element count).

Execution and Postprocessing

To run the neutronics calculation with AMR,

First, lets examine how the reported relative errors and the number of elements in the problem changes as the mesh is adaptively refined / coarsened:

We can see that avg_rel_err starts at ~1% on the first iteration and jumps to ~4% on the second iteration, which is corroborated by num_elem quadrupling on this step (from 46240 to 194080) indicating that a large amount of refinement is taking place. This behavior slows down on the third step as the number of elements remaining that meet both the spatial refinement criteria (optical depth) and the statistical error requirement (relative error less than 5%) are limited, and so the average relative error only increases to ~6% while another 52619 elements are added. Looking at max_rel_err we can also see that some elements meet the statistical error criteria before refinement, but after refinement their relative error overshoots the maximum error threshold and so the maximum relative error in the problem jumps to ~20%. We can see this behavior in Figure 4 where the heat source is initially refined semi-uniformly over the domain. Then, the elements near the core centerline and the edges of the assembly are marked for refinement due to an increase in the estimated optical depth from higher fission rates. After the third iteration the edge of the assembly nearest to the vacuum boundary and the corners of the assembly are marked for coarsening due to the jump in relative error. Running the simulation with additional particles per batch or more active batches would further decrease the per-element relative error and allow for added refinement steps. The jumps in relative error above the upper limit of 10% can also be mitigated by decreasing the refinement threshold in rel_error from 5% to 1%.

Figure 4: Elements marked for refinement (left), fission power (middle), and elements marked for coarsening (right) for the LWR assembly over multiple adaptivity cycles.

Single Pincell

In this section, we isolate a single pin from the corner of the assembly mesh to tally and run adaptivity on. The mesh input file (mesh_pin.i) can be found below. We first generate a UO pin, and translate it to ensure it lines up with a fuel pin (as the central pin in the assembly is a fission chamber). This pin is then extruded to the full length of the fueled region and the gap block is deleted (as it will never be tallied on).

The mesh can be generated by running:

The first modification made to openmc_amr.i is to change the mesh block such that it tallies on the single pin mesh:

The second modification is to set particles = 1000 to ensure this problem is runnable with modest computational resources:

Execution and Postprocessing

To run the single pin problem,

First, lets examine how the reported relative errors and the number of elements in the problem changes as the mesh is adaptively refined / coarsened:

The behavior of the relative error for the single pincell is similar to the full assembly case, though the reduced number of particles per batch decreases the amount of refinement that the model can support. avg_rel_err starts at ~5% on the first iteration, and then jumps to ~9% due to the addition of more elements on the second iteration. The selected adaptivity scheme then coarsens those elements which results in a decrease in max_rel_err from ~17% on iteration two to ~15% on iteration three - the maximum doesn't decrease a substantial amount as certain elements have a relative error less than 5% and refine to a relative error larger than 10%. We can see this behaviourin Figure 5, where the adaptivity algorithm initially over-refines and then coarsens to ensure the relative error of the tally bins is between 5% and 10%

Figure 5: Elements marked for refinement (left), fission power (middle), and elements marked for coarsening (right) for a single pincell over multiple adaptivity cycles.

References

- S. Cathalau, J. C. Lefebvre, and J. P. West.

Proposal for a Second Stage of the Benchmark on Power Distributions within Assemblies.

Technical Report NEA/NSC/DOC(96)2, Organisation for Economic Cooperation and Development, Nuclear Energy Agency, 1996.

URL: https://www.oecd-nea.org/upload/docs/application/pdf/2020-01/nsc-doc96-02-rev2.pdf.[BibTeX]

- M.A. Smith, E.E. Lewis, and Byung-Chan Na.

Benchmark on Deterministic 3-D MOX Fuel Assembly Transport Calculations without Spatial Homogenization.

Progress in Nuclear Energy, 48(5):383–393, 2006.

doi:https://doi.org/10.1016/j.pnucene.2006.01.002.[BibTeX]