Conjugate Heat Transfer for Reflector Bypass Flow

In this tutorial, you will learn how to:

Couple NekRS with MOOSE for CHT in a pebble bed reactor reflector block

Propagate scalar values into the OCCA GPU kernels

To access this tutorial,

This tutorial also requires you to download some mesh files and restart files from Box. Please download the files from the fhr_reflector folder here and place these files within the same directory structure in tutorials/fhr_reflector.

This tutorial was developed with funding from the NRIC VTB. You can find additional context on this model in our conference publication Novak et al. (2021).

This tutorial requires HPC resources to run.

Geometry and Computational Model

The pebble region in the Pebble Bed Fluoride-Salt-Cooled High-Temperature Reactor (PB-FHR) is enclosed by an outer graphite reflector. In order to keep the graphite reflector within allowable design temperatures, the reflector contains several bypass flow paths so that a small percentage of the coolant flow can maintain the graphite within allowable temperature ranges. This bypass flow is important to quantify so that accurate estimates of core cooling and reflector temperatures can be obtained. By repeating these calculations for a range of Reynolds numbers and geometries, this model can be used to provide friction factor and Nusselt number correlations.

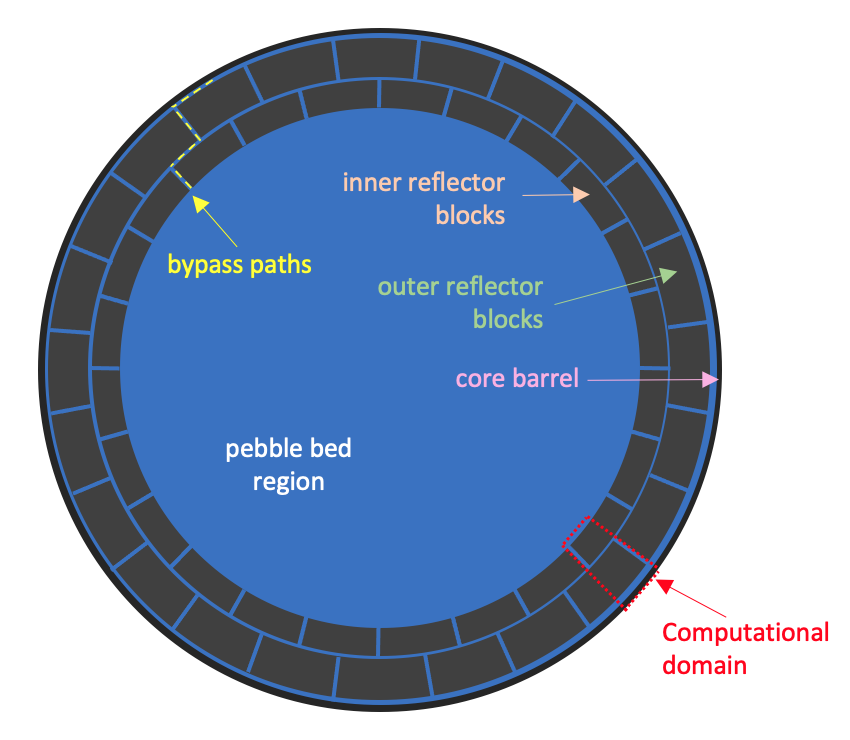

This section describes the PB-FHR reflector geometry and our computational model. A top-down view of the PB-FHR reactor is shown in Figure 1, with important specifications summarized in Table 1. The center region is the pebble bed core, which is surrounded by two rings of graphite reflector blocks, staggered in a brick-like fashion. The nominal gap size between blocks is 0.002 m, but to ease meshing and make model depiction easier, the gap between blocks is increased to 0.006 m (which could be interpreted as an end-of-life, maximum-swelling condition Novak et al. (2021)). Each ring contains 24 blocks. In black is shown the core barrel. To form the entire axial height of the reflector, rings of blocks are stacked vertically. The entire core height is 5.3175 m, or about 10 vertical rings of blocks. Additional structures are present as well, but are not considered here.

Figure 1: Top-down schematic of the PB-FHR reactor core.

Table 1: Geometric and operating conditions relevant to reflector block modeling, based on Shaver et al. (2019)

| Parameter | Value |

|---|---|

| Pebble core radius | 2.6 m |

| Inner block radial thickness | 0.3 m |

| Outer block radial thickness | 0.4 m |

| Barrel thickness | 0.022 m |

| Gap between blocks | 0.006 m |

| Gap between blocks and barrel | 0.02 m |

| Block height | 0.52 m |

| Core inlet temperature | 600°C |

| Core outlet temperature | 700°C |

FLiBe flows through the pebble bed, through small gaps between reflector blocks, and between small gaps between the reflector blocks and the barrel. These bypass paths are shown as yellow dashed lines in Figure 1. Due to the top-down orientation of Figure 1, flow paths radially (i.e. from lower to higher at a fixed between stacks of reflector blocks) are not shown. While such radial bypass paths contribute to bypass flow, they are not considered here.

The coupled NekRS-MOOSE simulation is conducted for a single ring of reflector blocks (i.e. a height of 0.52 m), with azimuthal symmetry assumed to further reduce the domain to half of an inner ring block, half of an outer ring block, and the vertical bypass flow paths between the blocks and the barrel. This computational domain is shown outlined with a red dotted line in Figure 1.

Heat Conduction Model

The MOOSE heat transfer module is used to solve for energy conservation in the solid. A fixed heat flux of 5 kW/m is imposed on the block surface facing the pebble bed. On the surface of the barrel, a heat convection boundary condition is imposed,

(1)

where is the heat flux, is the convective heat transfer coefficient, and is the far-field ambient temperature. At fluid-solid interfaces, the solid temperature is imposed as a Dirichlet condition, where NekRS computes the surface temperature. All other solid boundaries are treated as insulated.

NekRS Model

NekRS is used to solve the incompressible Navier-Stokes equations in non-dimensional form. In this tutorial, the following characteristic scales are selected:

m, such that the block gap width is unity

m/s, which corresponds to a Reynolds number of 100

K, the inlet temperature

K, an arbitrary selection

A Reynolds number of 100 corresponds to a bypass fraction of about 7%, considering that can be written equivalently as

(2)

where is the mass flowrate (a fraction of the total core mass flowrate, distributed among 48 half-reflector blocks) and is the inlet flow area.

The only characteristic scale that requires additional comment is - this parameter truly is arbitrary, since it does not appear in the definitions of or (and, none of the initial conditions/kernels in NekRS's case files assume any range for temperature). That is, if the converged solution has an inlet temperature of 400 K and an outlet temperature of 500 K, setting means that will range from 0 to 1. Setting a different value, such as , means that will instead range from 0 to 2. The only scenario where is of consequences is if you are setting initial conditions for temperature or have imposed a heat source yourself within the .oudf file.

At the inlet, the fluid temperature is taken as 650°C, or the nominal median fluid temperature. The inlet velocity is set to a uniform value such that the Reynolds number is 100. At the outlet, a zero pressure is imposed. On the boundary (i.e. the boundary), symmetry is imposed such that all derivatives in the direction are zero. All other boundaries are treated as no-slip.

The boundary (i.e. divided by 24 blocks, divided in half because we are modeling only half a block) should also be imposed as a symmetry boundary in the NekRS model. However, at the time when we first made this tutorial, NekRS only supported symmetry boundaries for sidesets aligned with the , , and coordinate axes. Here, a no-slip boundary condition is used instead, so the correspondence of the NekRS computational model to the depiction in Geometry and Computational Model is imperfect. This is no longer a restriction in NekRS.

At fluid-solid interfaces, the heat flux is imposed as a Neumann condition, where MOOSE computes the surface heat flux.

Because the NekRS mesh contains very small elements in the fluid phase, fairly small time steps are required to meet CFL conditions related to stability. Therefore, the approach to the coupled, pseudo-steady CHT solution can be accelerated by obtaining initial conditions from a pure conduction simulation. Then, the initial conditions for the CHT simulation will begin from the temperature obtained from the conduction simulation, with a uniform axial velocity and zero pressure. The process to run Cardinal in conduction mode is described in Part 1: Initial Conduction Coupling , while the process to run Cardinal in CHT mode is described in Part 2: CHT Coupling .

Meshing

Cubit SNL (2012) is used to programmatically create meshes with user-defined geometry and customizable boundary layers. Journal files, or Python-scripted Cubit inputs, are used to create meshes in Exodus II format. The MOOSE framework accepts meshes in a wide range of formats that can be generated with many commercial and free meshing tools; other tutorials will make meshes natively within MOOSE.

Solid Mesh

The Cubit script used to generate the solid mesh is shown below. To run this script yourself, open Cubit and click on 'Play Journal File' (the play button on a sheet of paper icon), and then find and open your file. Also, you will need to update the directory variable to point to the tutorials directory on your machine.

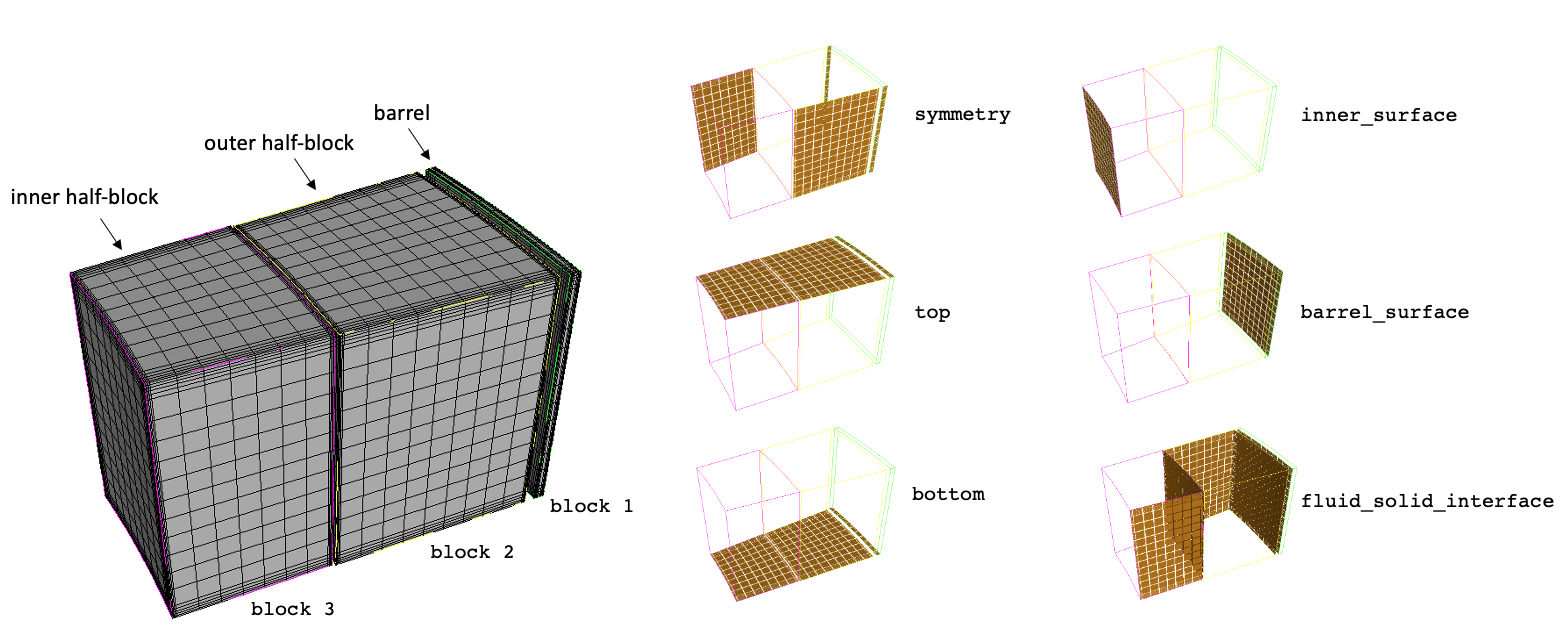

The solid mesh (before a series of refinements) is shown below; the boundary names are illustrated by showing only the highlighted surface to which each boundary corresponds. A unique block ID is used for the set of elements corresponding to the inner ring, outer ring, and barrel. Material properties in MOOSE are typically restricted by block, and setting three separate IDs allows us to set different properties in each of these blocks.

Figure 2: Solid mesh for the reflector blocks and barrel and a subset of the boundary names, before a series of mesh refinements

Unique boundary names are set for each boundary to which we will apply a unique boundary condition; we define the boundaries on the top and bottom of the block, the symmetry boundaries, and boundaries at the interface between the reflector and the bed and on the barrel surface.

One convenient aspect of MOOSE is that the same elements can be assigned to more than one boundary ID. To help in applying heat flux and temperature boundary conditions between NekRS and MOOSE, we define another boundary that contains all of the fluid-solid interfaces through which we will exchange heat flux and temperature, as fluid_solid_interface.

Fluid Mesh

The Cubit script used to generate the fluid mesh is shown below. To run this script yourself, you will need to update the directory variable to point to the tutorials directory on your machine.

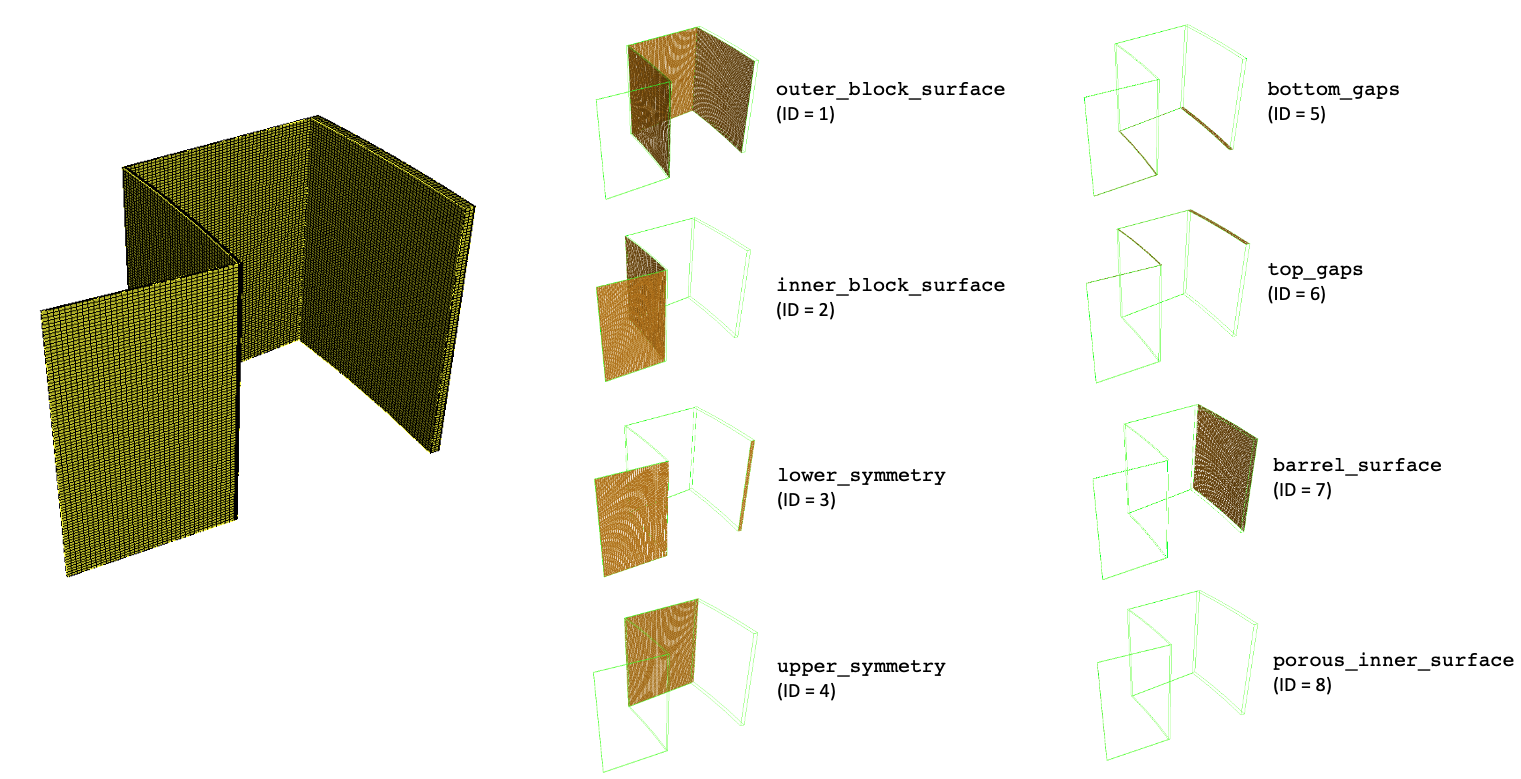

The fluid mesh is shown below; the boundary names are illustrated towards the right by showing the highlighted surface to which each boundary corresponds. While the names of the surfaces are shown, NekRS does not directly use these names - rather, NekRS assigns boundary conditions based on the boundary ID. An important restriction in NekRS is that the boundary IDs be ordered sequentially beginning from 1.

Figure 3: Fluid mesh for the FLiBe flowing around the reflector blocks, along with boundary names and IDs. It is difficult to see, but the porous_inner_surface boundary corresponds to the thin surface at the interface between the reflector region and the pebble bed.

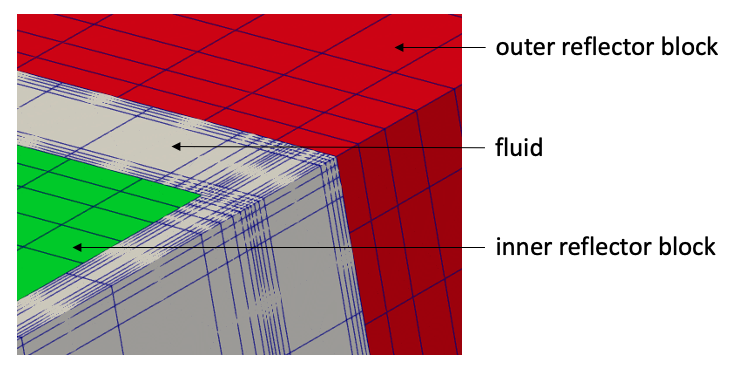

One strength of Cardinal for CHT applications is that the fluid and solid meshes do not need to share nodes on a common surface; MOOSE mesh-to-mesh data interpolations can communicate between surfaces with different refinement and position in space; meshes may even overlap or share no nodes at all, such as for curvilinear applications. Figure 4 shows a zoom-in of the two mesh files (for the fluid and solid phases). Each phase can be meshed according to its physics requirements.

Figure 4: Zoomed-in view of the fluid and solid meshes, overlaid in Paraview. Lines are element boundaries.

Because NekRS uses a custom binary mesh format with a .re2 extension, the exo2nek utility must be used to convert an Exodus II format to .re2 format. For more information, please consult the tools documentation.

Part 1: Initial Conduction Coupling

In this section, NekRS and MOOSE are coupled for conduction heat transfer in the solid reflector blocks and barrel, and through a stagnant fluid. The purpose of this stage of the analysis is to obtain a restart file for use as an initial condition in Part 2: CHT Coupling to accelerate the NekRS calculation for CHT. All input files for this stage are present in the tutorials/fhr_reflector/conduction directory. The following sub-sections describe these files.

Solid Input Files

The solid phase is solved with the MOOSE heat transfer module, and is described in the solid.i input. At the top of this file, the core heat flux is defined as a variable local to the file.

Next, the solid mesh is specified by pointing to the Exodus mesh.

(tutorials/fhr_reflector/conduction/solid.i)The heat transfer module will solve for temperature, which is defined as a nonlinear variable.

(tutorials/fhr_reflector/conduction/solid.i)The Transfer system is used to communicate auxiliary variables across applications; a boundary heat flux will be computed by MOOSE and applied as a boundary condition in NekRS. In the opposite direction, NekRS will compute a surface temperature that will be applied as a boundary condition in MOOSE. Therefore, both the flux (flux) and surface temperature (nek_temp) are declared as auxiliary variables. The solid app will compute flux, while nek_temp will simply receive a solution from NekRS.

An initial condition is set for nek_temp using a function.

Next, the governing equation solved by MOOSE is specified with the Kernels block.

Next, the boundary conditions on the solid are applied. On the fluid-solid interface, a MatchedValueBC applies the value of the nek_temp receiver auxiliary variable to the temperature in a strong Dirichlet sense. Insulated boundary conditions are applied on the symmetry, top, and bottom boundaries. On the boundary at the bed-reflector interface, the core heat flux is specified as a NeumannBC. Finally, on the surface of the barrel, a heat flux of is specified, where both and are specified as material properties.

The HeatConduction kernel requires a material property for the thermal conductivity; material properties are also required for the heat transfer coefficient and far-field temperature for the ConvectiveHeatFluxBC boundary condition. These material properties are specified in the Materials block. Here, different values for thermal conductivity are used in the graphite and steel.

Next, the MultiApps and Transfers blocks describe the interaction between Cardinal and MOOSE. The MOOSE heat transfer module is here run as the main application, with the NekRS wrapping run as the sub-application. We specify that MOOSE will run first on each time step.

Three transfers are required to couple Cardinal and MOOSE; the first is a transfer of surface temperature from Cardinal to MOOSE. The second is a transfer of heat flux from MOOSE to Cardinal. And the third is a transfer of the total integrated heat flux from MOOSE to Cardinal (computed as a postprocessor), which is then used internally by NekRS to re-normalize the heat flux (after interpolation onto NekRS's GLL points).

(tutorials/fhr_reflector/conduction/solid.i)Next, postprocessors are used to compute the integral heat flux as a SideIntegralVariablePostprocessor.

(tutorials/fhr_reflector/conduction/solid.i)Finally, a transient executioner is used for the solid phase. The overall coupled simulation is considered converged once the relative change in the solution between steps is less than . An output format of Exodus II is specified.

(tutorials/fhr_reflector/conduction/solid.i)Fluid Input Files

The fluid phase is solved with NekRS. The wrapping of NekRS as a MOOSE application is specified in the nek.i file.

First, a local variable, fluid_solid_interface, is used to define all the boundary IDs through which NekRS is coupled via CHT to MOOSE. A first-order mirror of the NekRS mesh is constructed using the NekRSMesh. By specifying the boundary parameter, we are indicating that NekRS will be coupled via CHT through boundaries 1, 2, and 7 to MOOSE. In order for MOOSE's transfers to correctly find the closest nodes in the solid mesh to corresponding nodes in this fluid mesh mirror, the entire mesh must be scaled by a factor of to return to dimensional units (because the coupled MOOSE application is in dimensional units). This scaling is specified by the scaling parameter.

Next, the NekRSProblem specifies that NekRS simulations will be run in place of MOOSE. To allow conversion between a non-dimensional NekRS solve and a dimensional MOOSE coupled heat conduction application, the characteristic scales used to establish the non-dimensional problem are provided.

(tutorials/fhr_reflector/conduction/nek.i)Next, a Transient executioner is specified with the NekTimeStepper, which allows NekRS to control its own time stepping (except for synchronization points).

(tutorials/fhr_reflector/conduction/nek.i)Finally, several postprocessors are included to perform integrals and global min/max calculations over the NekRS domain for diagnostic purposes. Here, the NekHeatFluxIntegral postprocessor computes over a boundary in the NekRS mesh. The NekVolumeExtremeValue postprocessors then compute the maximum and minimum temperatures throughout the entire NekRS domain (i.e. not only on the CHT coupling surfaces).

(tutorials/fhr_reflector/conduction/nek.i)The nek.i input file only describes how NekRS is wrapped within the MOOSE framework; each NekRS simulation requires additional files that share the same case name fluid but with different extensions. The additional NekRS files are:

fluid.re2: Mesh filefluid.par: High-level settings for the solver, boundary condition mappings to sidesets, and the equations to solvefluid.udf: User-defined C++ functions for on-line postprocessing and model setupfluid.oudf: User-defined OCCA kernels for boundary conditions and source terms

First, begin with the fluid.par file.

Here, a time step of 0.025 (non-dimensional) is used; a NekRS output file is written every 100 time steps. Because the purpose of this simulation is only to obtain a reasonable initial condition, a low polynomial order of 2 is used.

Next, the [VELOCITY] and [PRESSURE] blocks describe the solution of the pressure Poisson equation and velocity Helmholtz equations. In the velocity block, setting solver = none turns off the velocity solution; therefore, none of the parameters specified here are used right now, so their description will be deferred to Part 2: CHT Coupling . Finally, the [TEMPERATURE] block describes the solution of the temperature passive scalar equation. is set to unity because the solve is conducted in non-dimensional form, such that

(3)

The coefficient on the diffusive equation term in the non-dimensional energy equation is equal to . In NekRS, specifying conductivity = -1500.5 is equivalent to specifying conductivity = 0.00066644 (i.e. ), or a Peclet number of 1500.5.

Next, residualTol specifies the solver tolerance for the temperature equation to . Finally, the boundaryTypeMap is used to specify the mapping of boundary IDs to types of boundary conditions. Boundaries 1, 2, and 7 are flux boundaries (these boundaries will receive a heat flux from MOOSE), boundaries 3, 4, and 8 are insulated, boundary 5 is a specified temperature, and boundary 6 is a zero-gradient outlet. The actual assignment of values for these boundary conditions is then performed in the fluid.oudf file. Because this case does not have any user-defined source terms in NekRS, these OCCA kernels are only used to apply boundary conditions.

Finally, the fluid.udf file contains user-defined C++ functions through which other interactions with the NekRS solution are performed. Here, the UDF_Setup function is called once at the very start of the NekRS simulation, and it is here that initial conditions are applied.

The initial condition is applied by looping over all the GLL points and setting zero to each (recall that this is a non-dimensional simulation, such that corresponds to a dimensional temperature of ). Here, nrs->cds->S is the array holding the NekRS passive scalar solutions (of which there is only one for this example).

Execution and Postprocessing

To run the pseudo-steady conduction model, run the following:

which will run with 48 MPI ranks. When the simulation has completed, you will have created a number of different output files:

fluid0.f<n>, where<n>is a five-digit number indicating the output file number created by NekRS (a separate output file is written for each time step according to the settings in thefluid.parfile). An extra program is required to visualize NekRS output files in Paraview; see the instructions here.solid_out.e, an Exodus II output file with the solid mesh and solution.solid_out_nek0.e, an Exodus II output file with the fluid mirror mesh and data that was ultimately transferred in/out of NekRS.

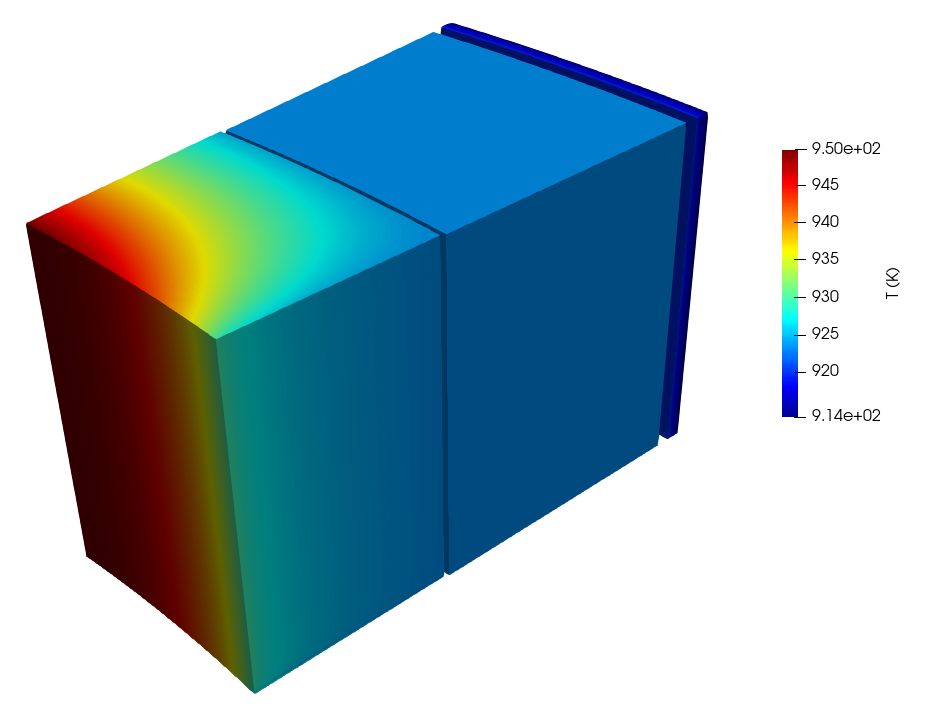

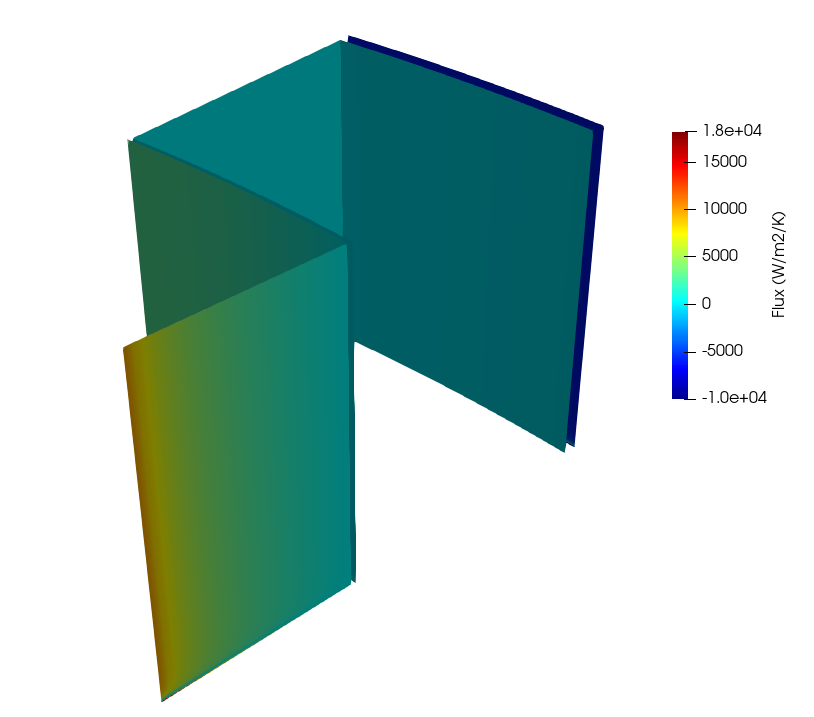

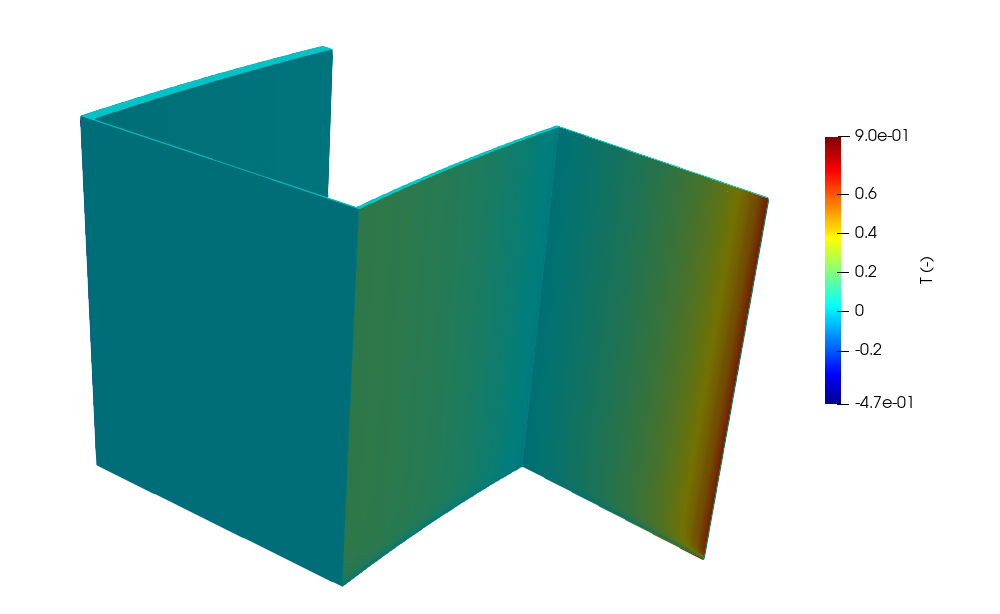

After converting the NekRS output files to a format viewable in Paraview, the simulation results can be displayed. The solid temperature, surface heat flux, and fluid temperature are shown below. Note that the fluid temperature is shown in nondimensional form based on the selected characteristic scales. The image of the fluid solution is rotated so as to better display the temperature variation around the inner reflector block. The domain shown in Figure 6 exactly corresponds to the "mirror" mesh constructed by NekRSMesh.

Figure 5: Solid temperature for steady state conduction coupling between MOOSE and NekRS

Figure 6: Solid surface heat flux for steady state conduction coupling between MOOSE and NekRS

Figure 7: Fluid temperature (nondimensional) for steady state conduction coupling between MOOSE and NekRS

The solid blocks are heated by the pebble bed along the bed-reflector interface, so the temperatures are highest in the inner block. As can be seen in Figure 6, the heat flux into the fluid is in some places positive (such as near the inner reflector block) and is in other places negative (such as near the barrel) where heat leaves the system.

Part 2: CHT Coupling

In this section, NekRS and MOOSE are coupled for CHT with fluid flow. All input files for this stage of the analysis are present in the tutorials/fhr_reflector/cht directory. The following sub-sections describe all of these files; for brevity, most emphasis will be placed on input file setup that is different or extends the conduction case in Part 1: Initial Conduction Coupling .

Solid Input Files

The solid phase is again solved with the MOOSE heat transfer module; the input file is largely the same except that the simulation is run for 400 time steps.

(tutorials/fhr_reflector/cht/solid.i)Fluid Input Files

The fluid phase is solved with NekRS. The input file is largely the same as the conduction case, except that additional postprocessors are added to query more aspects of the NekRS solution. The postprocessors are shown below.

(tutorials/fhr_reflector/cht/nek.i)We have added postprocessors to compute the average inlet pressure and the average inlet and outlet mass flowrates. Like the NekVolumeExtremeValue postprocessor, these postprocessors operate directly on NekRS's internal solution arrays to provide diagnostic information. Because the outlet pressure is set to zero, pressure_in corresponds to the pressure drop in the fluid.

As in Part 1: Initial Conduction Coupling , additional files are required to set up the NekRS simulation - fluid.re2, fluid.par, fluid.udf, and fluid.oudf. These files are largely the same as those used in the steady conduction model, so only the differences will be emphasized here. The fluid.par file is shown below. Here, startFrom provides a restart file (that we generated from Part 1: Initial Conduction Coupling ), conduction.fld and specifies that we only want to read temperature from the file (by appending +T to the file name). We increase the polynomial order as well.

In the [VELOCITY] block, the density is set to unity, because the solve is conducted in nondimensional form, such that

(4)

The coefficient on the diffusive term in the non-dimensional momentum equation is equal to . In NekRS, specifying diffusivity = -100.0 is equivalent to specifying diffusivity = 0.001 (i.e. ), or a Reynolds number of 100.0. All other parameters have similar interpretations as described in Part 1: Initial Conduction Coupling .

The fluid.udf file is shown below. The UDF_Setup function is again used to apply initial conditions; because temperature is read from the restart file, only initial conditions on velocity and pressure are required. nrs->U is an array storing the three components of velocity (padded with length nrs->fieldOffset), while nrs->P is the array storing the pressure solution.

This file also includes the UDF_LoadKernels function, which is used to propagate quantities to variables accessible through OCCA kernels. The kernelInfo object is used to define two variables - Vz and inlet_T that will be accessible through the Graphics Processing Unit (GPU) kernels, eliminating some burden on the user if the problem setup must be changed in multiple locations throughout the NekRS input files.

Finally, the fluid.oudf file is shown below. Because the velocity is enabled, additional boundary condition functions must be specified. In the velocityDirichletConditions function, the kernel variable Vz was defined in the fluid.udf file. The other boundary conditions - the Dirichlet temperature conditions and the Neumann heat flux conditions - are the same as for the steady conduction case.

Execution and Postprocessing

To run the pseudo-steady CHT model, run the following:

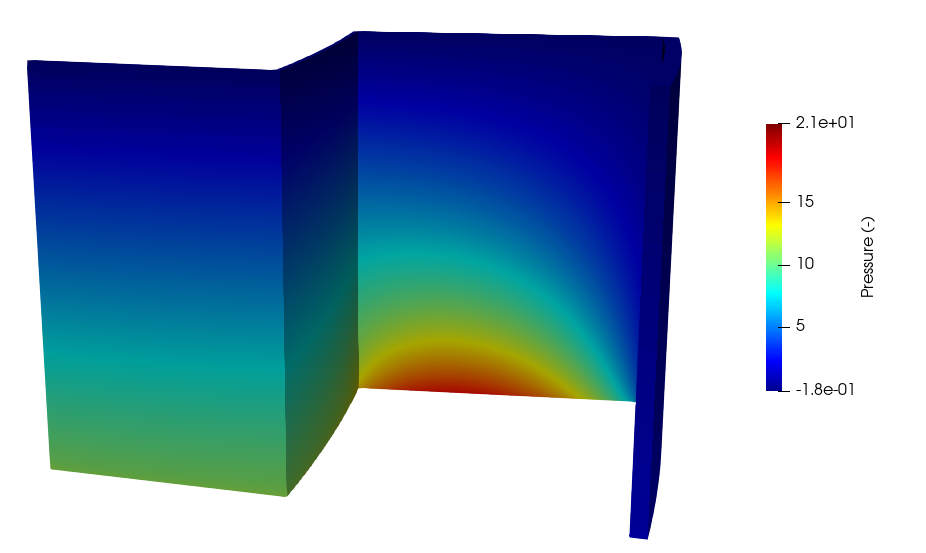

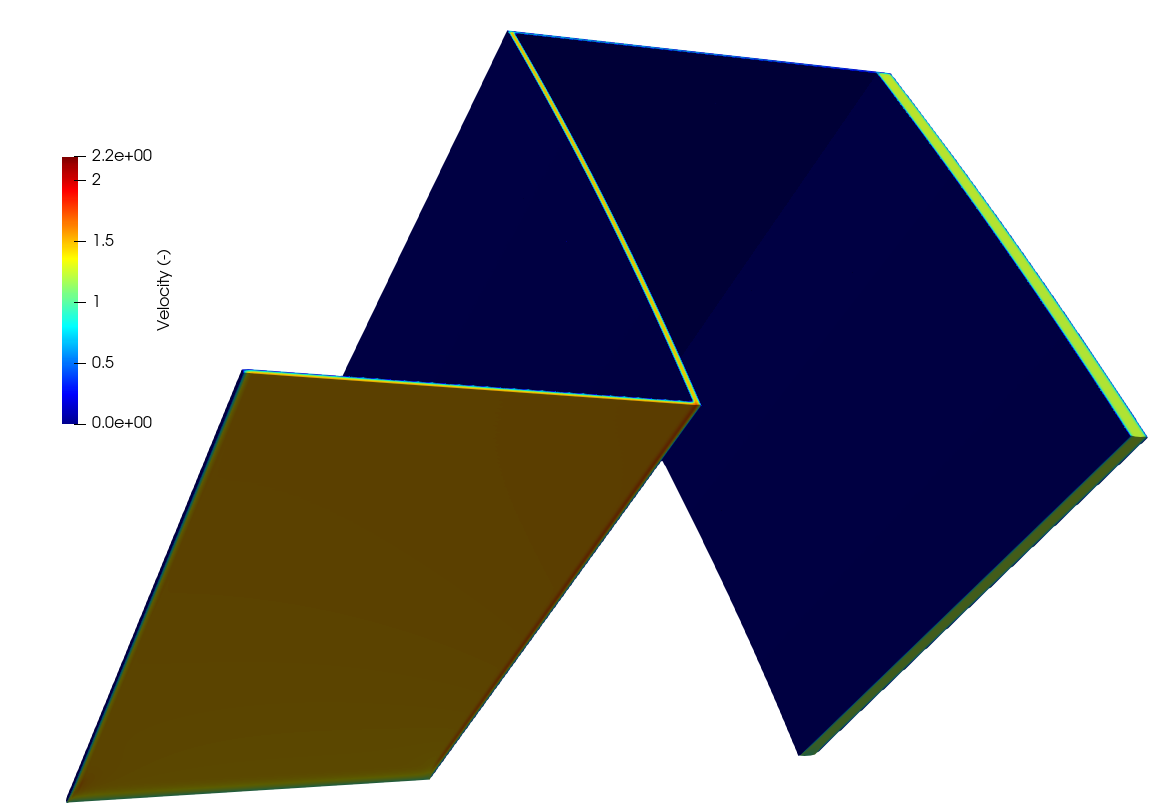

The pressure and velocity distributions are shown below, both in non-dimensional form.

Figure 8: Pressure (nondimensional) for CHT coupling between MOOSE and NekRS

Figure 9: Velocity (nondimensional) for CHT coupling between MOOSE and NekRS

The no-slip condition on the solid surface, and the symmetry condition on the surface, are clear in Figure 9. The pressure loss is highest in the gap along the boundary due to the imposition of no-slip conditions on both sides of the half-gap width.

References

- A.J. Novak, S. Schunert, R.W. Carlsen, P. Balestra, R.N. Slaybaugh, and R.C. Martineau.

Multiscale thermal-hydraulic modeling of the pebble bed fluoride-salt-cooled high-temperature reactor.

Annals of Nuclear Energy, 2021.

doi:10.1016/j.anucene.2020.107968.[BibTeX]

- A.J. Novak, D. Shaver, and B. Feng.

Conjugate Heat Transfer Coupling of NekRS and MOOSE for Bypass Flow Modeling.

In Proceedings of ANS. 2021.[BibTeX]

- D. Shaver, R. Hu, L. Zou, and E. Merzari.

Initial Industry Collaborations of the Center of Excellence.

Technical Report ANL/NSE-19/15, Argonne National Laboratory, 2019.

URL: https://www.osti.gov/biblio/1556071.[BibTeX]

- SNL.

CUBIT 13.2 User Documentation.

2012.

URL: https://tinyurl.com/rgsbqb7.[BibTeX]